- Inspect

- Fuel system components, including visible and readily accessible tanks, lines, pipes, valves, filler pipes, vents, and meters

- Visible and readily accessible fuel supply system(s)

- Describe

- Type and location of fuel storage

- Location of fuel shut-off valve(s)

- Not required

- Public or private utility fuel service

- Ownership of fuel tanks associated with the property

Tanks

On-site fuel oil and propane tanks provide a homeowner with both great convenience and flexibility in choosing how to heat their homes and what type of water heating or cooking appliances they use. They also mean that we have 275 gallons of flammable liquid or 100-500 gallons of liquefied explosive gas right on the property. On top of that are the lines and pipes that carry those products into the home’s interior. Now the importance of our work in this category comes into better focus!

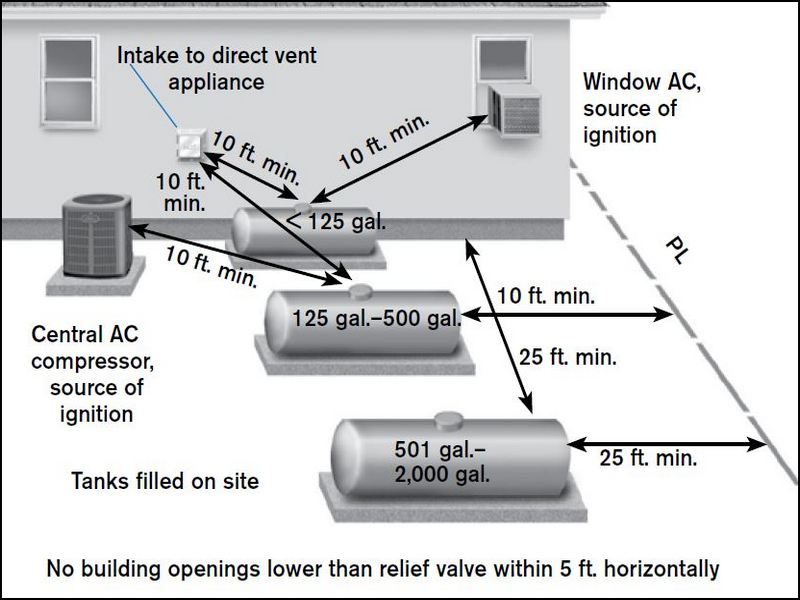

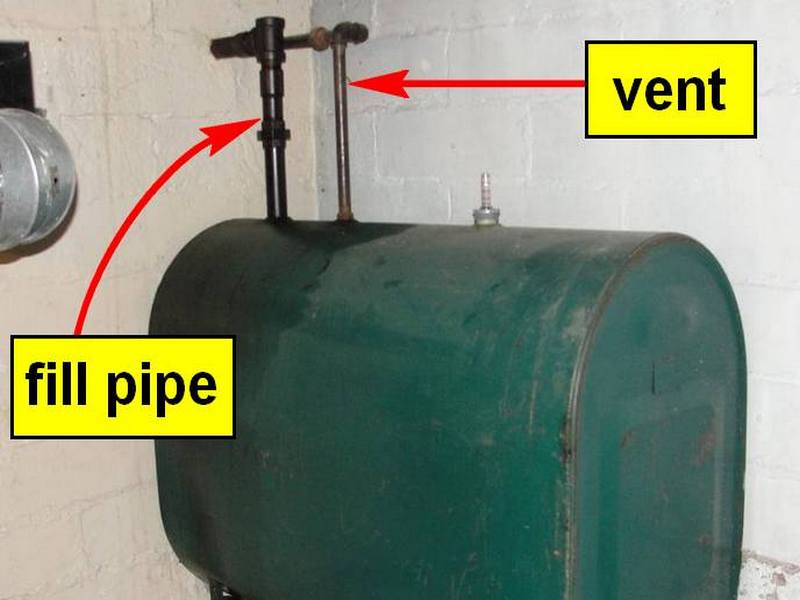

We must accurately identify the type(s) of fuel being used, where the tank(s) is, and where the main shut-off valve(s) is. Take photos of the tank and valve. Inspect for condition, leaks, proper venting, abandoned fill pipes, missing valves and filters. Underground oil storage tanks (UST) are always reported. Smaller propane tanks (100 gallons/420 lbs) cannot be within 5 feet of a low house opening such as a crawlspace vent. Larger tanks (500 gallons) must be 10′ from house openings and/or ignition sources (AC units, exhaust fans). Be alert to evidence that the wrong gas is being used for the appliance. Furnaces and water heaters are clearly labeled. Improper burner flame characteristics should be reported.

Propane Tank Clearances

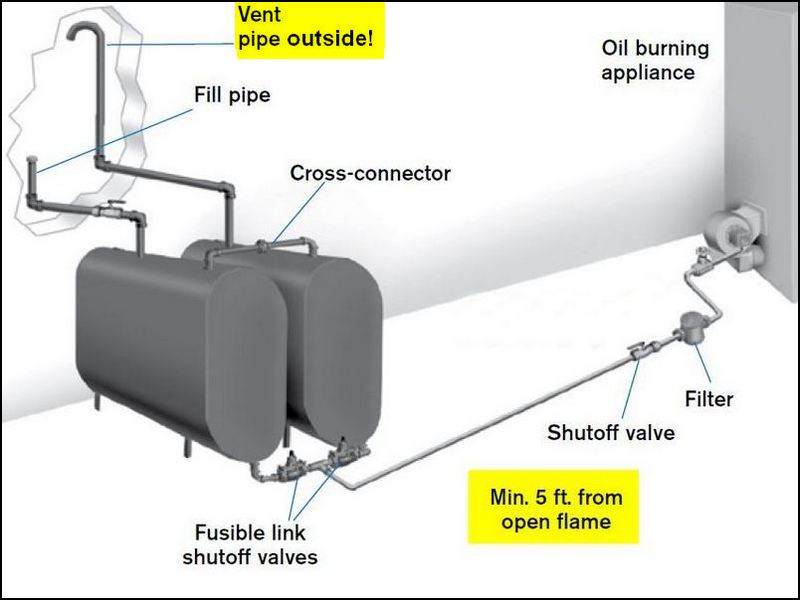

Indoor oil tanks

The fuel storage tank is improperly located. This is a safety concern. Hire a contractor to relocate the tank to a proper location.

The fuel storage tank is leaning or unstable. This is a safety concern as the tank may fall. Hire a contractor to secure the tank.

The fuel storage tank supports are corroded. This is a safety hazard. Hire a contractor to replace the supports.

The fuel storage tank is corroded. This may allow fuel to leak. Hire a contractor to replace the tank.

The fuel storage tank is leaking. This is a health and safety hazard. Hire a contractor to evaluate the tank and to make required repairs.

The fuel storage tank shows evidence of leaks and past repairs. This makes the tank’s reliability questionable. Hire a contractor to evaluate the tank and to make required repairs.

Metal straps holding rubber patches in place

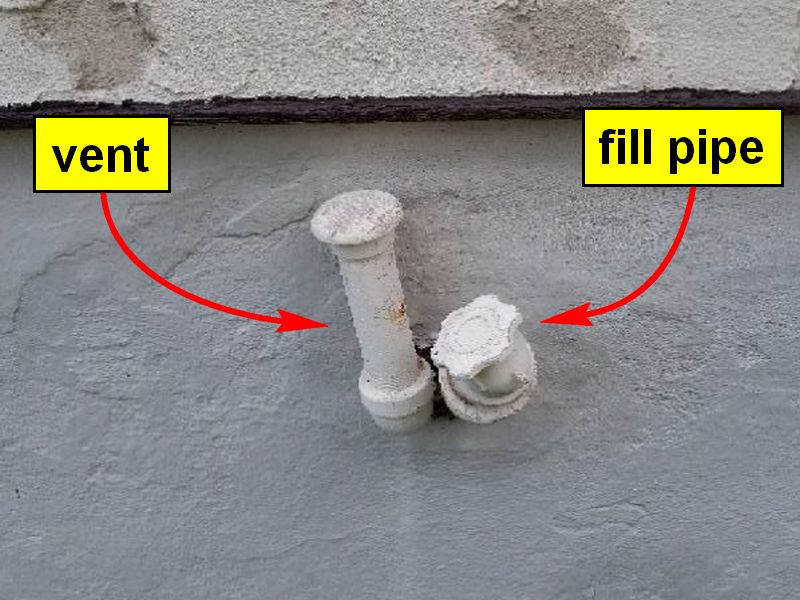

Both underground oil storage tanks (UST) and abandoned fuel tanks can present environmental hazards. Inspect carefully in basements, crawl spaces, and the yard for signs of a UST, e.g. cut-off oil lines and vent or filler pipes.

There is evidence of a possible underground fuel storage tank on the property. This is a risk for leaks and would be a costly environmental clean-up. Hire an environmental specialist to evaluate the tank and to propose required actions.

There is an abandoned or decommissioned fuel tank. The tank may represent an environmental risk. Hire an environmental specialist to evaluate the tank and to propose required actions.

The fuel lines are not protected against damage. This is a safety hazard. Hire a plumber to add protection to the line.

The fuel line is damaged. This is a safety hazard. Hire a plumber to replace the line.

The oil fill pipe is not connected to a tank. This is a safety hazard that can allow fuel to be pumped into the interior of the home. Hire a plumber or HVAC contractor for repairs as needed.

The oil fill pipe is leaking. This is a safety hazard. Hire a plumber or HVAC contractor for repairs as needed.

The oil fill pipe is loose or damaged. This is a safety hazard. Hire a plumber or HVAC contractor for repairs as needed.

The oil fill pipe is corroded. This is a safety hazard. Hire a plumber or HVAC contractor for repairs as needed.

The oil fill pipe cap is missing. This is a safety hazard. Replace the fill pipe cap.

The fuel shut-off valve is damaged or leaking. This is a safety hazard. Hire a plumber or HVAC contractor for repairs as needed.

The fuel shut-off valve is corroded. This is a safety hazard. Hire a plumber or HVAC contractor for repairs as needed.

The fuel shut-off valve is missing. This is a safety hazard. Hire a plumber or HVAC contractor for repairs as needed.

The fuel system vent is inside the house. This is a safety hazard. Hire a plumber or HVAC contractor for repairs as needed.

Indoor oil tanks must have their vents outside

The fuel system vent pipe cap is loose or missing. This can allow debris and contamination into the tank. Secure or replace the cap.

Fuel oil filter systems have long been cartridge devices similar to a car’s filter.

Newer “Tiger Loop” systems are sealed and pressurized. They reduce aeration in the oil for cleaner, more efficient combustion.

The fuel oil filter is leaking. This is a safety concern. Hire a plumber or HVAC contractor for repairs as needed.

The fuel oil filter is missing. A filter is needed to trap contaminants and keep the particles from clogging the oil burner. Hire a plumber or HVAC contractor for repairs as needed.

Tanks Limitation and Information Statements

Pilot light off, no operation: The pilot light is off, which prevents system operation and limits the inspection.

Underground tanks not visible, limited inspection: Underground gas and fuel oil storage tanks are largely or entirely not visible. Therefore, the inspection is limited.

Near/at end useful life, budget for replacement: The fuel tank is near or at the end of its useful life. We recommend establishing a budget to replace the fuel tank.

Past end useful life, budget for replacement: The fuel tank is past the end of its useful life. We recommend establishing a budget to replace the fuel tank.

Copper fuel oil lines under flooring, common in older buildings, not permitted by current standards, possible environmental concerns, install oil safety valve: There are copper fuel oil lines under the flooring, which is common in older buildings but is not permitted per current industry standards. Copper fuel lines can interact with concrete and cause corrosion, deterioration, and leakage under the floor. Environmental concerns and costly clean-ups are possible. Install an oil safety valve as close as possible to the oil supply tank, which would help to prevent oil leaks from deteriorated lines under the floor. The valve requires a vacuum on the outlet side in order to open and allow the oil to flow, i.e., when the heating system’s burner is off, there is no vacuum and the oil flow is stopped.

Meter

In the component “Fuel Services – Meter” we are looking at a fuel gas system that is connected to the home and supplied constantly from a remote location. This is most commonly natural gas, but can be LP. When LP or #2 heating oil is delivered to a property, the metering for the fuel’s cost is done at the truck. The on-site supply will often have a regulator. The meters in this component track usage as well as provide regulation. Additionally, we will consider the various concerns with gas piping, including valves.

Inspect meters for a secure installation, damage or deterioration, debris, and protection from impact. Where relevant, seismic shut-off valves must be present. Always take photos and report the locations of the meter and the main shut-off. Evaluate gas pipes carefully. Be familiar with the concerns about CSST, including local requirements. You should know the difference between a drip leg and a sediment trap, and how they should be installed. Shut-off valves must be in place and in good condition at all gas appliances.

Seismic gas meter valves

The gas meter does not have a seismic shut-off valve. This is a safety hazard in earthquake-prone areas; they are required by some municipalities and insurance carriers. Hire a plumber for repairs as needed.

The gas meter lacks impact protection. It is installed in a vulnerable location. This is a safety hazard. Add impact protection to the meter.

The gas meter is partially buried in the ground or is covered by mulch. This can damage the equipment, and is a safety hazard. Clear the soil or mulch from the meter.

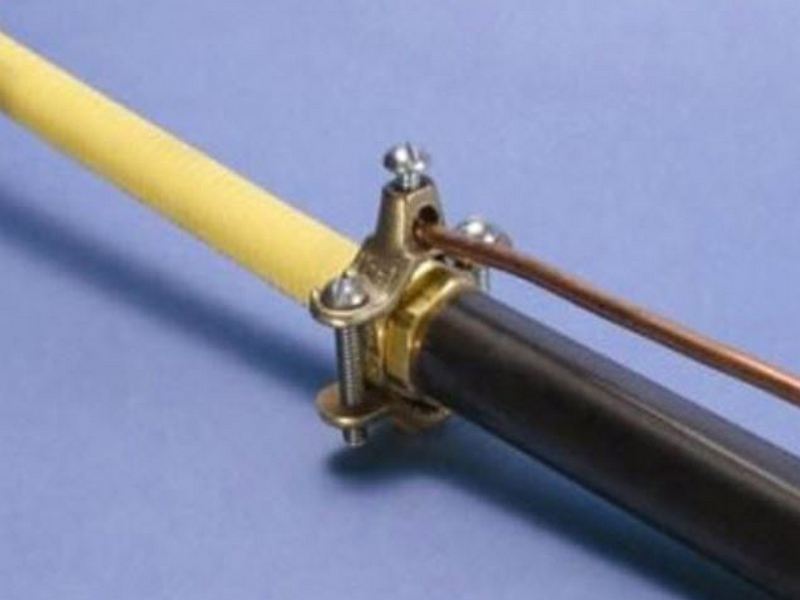

Corrugated Stainless Steel Tubing (CSST) gas piping must be bonded back to the system ground to avoid damage during lightning events.

A nearby strike can cause an arc that perforates the gas line.

Yellow CSST gas lines are present. Manufacturers believe that yellow corrugated stainless steel tubing (CSST) is safer if properly bonded and grounded as required by the manufacturer’s installation instructions. Proper bonding and grounding of CSST can be determined only by a Licensed Master Electrician. Hire a Licensed Master Electrician to properly bond and ground the lines.

The flexible appliance connector is improperly installed. It is passing though the cabinet of the appliance. Any excess vibrations can damage the line and cause a fuel leak. Hire a plumber to replace the connector or install protective bushings as required.

The gas lines are not protected against damage. This is a safety hazard. Hire a plumber to add protection to the line.

The gas line is damaged. This is a safety hazard. Hire a plumber to replace the line.

The gas lines are not properly supported. This is a safety hazard that can lead to leaks. Hire a plumber to properly support the line.

There is a gas service pipe with an open end which is readily accessible. This is an active line that has a shut-off valve that could be unintentionally opened. Hire a plumber for repairs as needed.

There are unmarked copper gas lines present. Accepted safe practice is to mark the lines in bright yellow to distinguish them from copper water pipes. Properly mark the lines.

The gas system is missing sediment traps. These are generally required at each appliance between the shutoff valve and the appliance to ensure reliable and safe operation.

The gas shut-off valve is damaged or leaking. This is a safety hazard. Hire a plumber or HVAC contractor for repairs as needed.

The gas shut-off valve is corroded. This is a safety hazard. Hire a plumber or HVAC contractor for repairs as needed.

The gas shut-off valve is missing. This is a safety hazard. Hire a plumber or HVAC contractor for repairs as needed.

Meter Limitation and Information Statements

Yellow CSST piping safer if properly bonded/grounded per manufacturer’s installation instructions, proper bonding/grounding determined only by licensed Master Electrician: Manufacturers believe that yellow Corrugated Stainless Steel Tubing (CSST) is safer if properly bonded and grounded as required by the manufacturer’s installation instructions. Proper bonding and grounding of CSST can be determined only by a licensed Master Electrician.