- Inspect

- Installed kitchen appliances using normal controls

- Laundry appliances that convey with the property

- Exhaust vents, catch pans, and faucets associated with laundry facilities

- Refrigerators, freezers, and ice makers that convey with the property

- Central vacuum systems if a sampling of outlets and the main canister can be tested without system accessories (i.e., by tripping low voltage contacts)

- Not required

- Appliances not fully installed or which could cause leakage or property damage, including washers when a secure drain hose connection cannot be confirmed

- Laundry appliances which contain personal items

- Central vacuum system accessories (hoses, attachments, etc.)

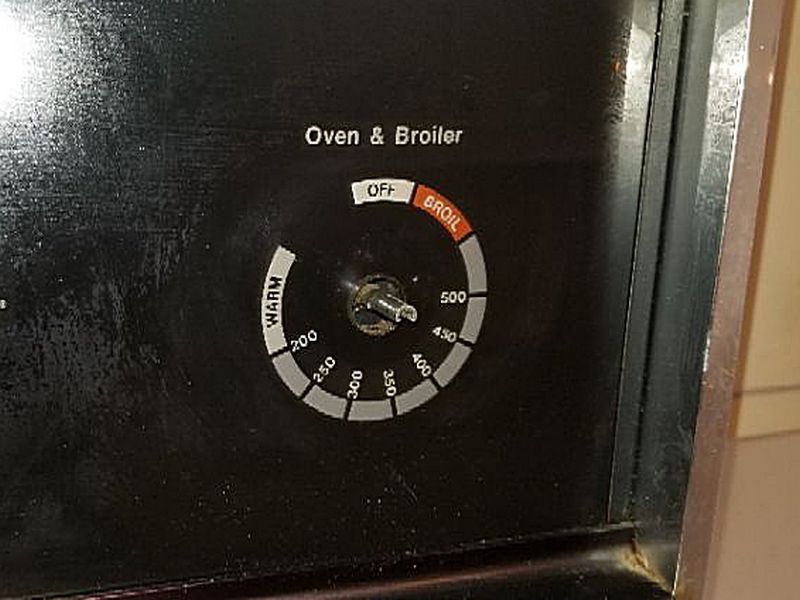

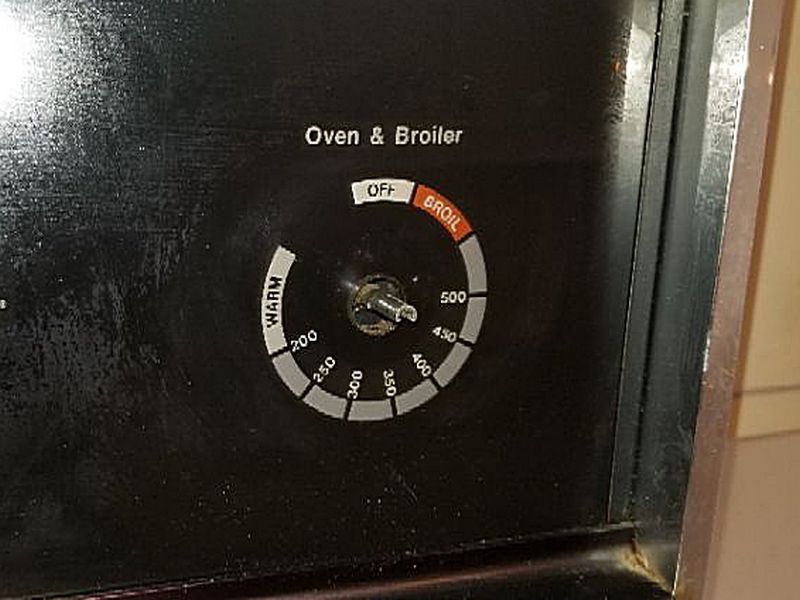

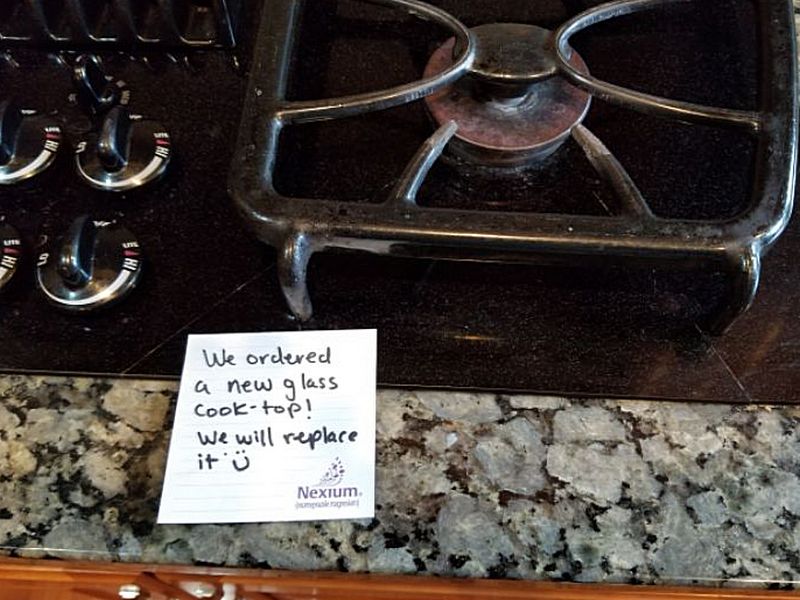

Range/Oven

If “the kitchen is the heart of a home”, then the cooking appliances are where the heartbeat comes from. Range/ovens are the most common style of this appliance. They have, as the name implies, both an oven compartment for baking and roasting and a cooktop surface. Range/ovens can be all-electric, all-gas, or a gas cooktop with an electric oven. Electric cooking requires a 240 volt connection; gas-only models just need 120 volts. Most units are completely free-standing on their own legs. “Drop-in” models fit into a cut-out in the countertop, and generally rest on a platform.

Range/Ovens share many inspection concerns with the components “Oven” and “Cooktop.” Safety and functionality are key. The top defect with free-standing units is a missing anti-tip bracket: this is a potential life safety issue. Always check inside the oven before testing it to ensure nothing’s in there, and never walk away from the appliance when operating the cooktop or oven. Assess the doors, door seals and handles, and convection fans when present (they may take a few minutes to start). Inspect for damage to a glass cooktop, missing cooktop or oven racks, and overall condition.

The range/oven’s anti-tip device is missing or improperly installed. This is a safety hazard that can allow the appliance to fall forward. Install an anti-tip device.

The range/oven is loose within its cabinet. This is a safety concern. Secure the range/oven.

The range/oven has one or more inoperative elements. This affects proper function. Repair or replace the elements.

The range/oven is inoperative. This prevents normal use. Repair or replace the range/oven.

The cooktop glass is broken. This affects proper operation and is a safety concern. Replace the glass.

The range/oven door glass is cracked. This is a safety concern. Repair or replace the glass or door.

The range/oven’s convection fan does not turn on during operation. This affects proper operation. Repair or replace the fan.

The range/oven door is broken. This is a safety concern. Repair or replace the door.

The range/oven door seal has failed. This affects proper operation. Replace the door seal.

The range/oven door springs are broken. This is a safety concern. Repair or replace the springs.

The range/oven door handle is broken or missing. This is a safety concern. Repair or replace the door handle.

The range/oven has significant interior damage or corrosion. This is a safety and reliability concern. Replace the range/oven.

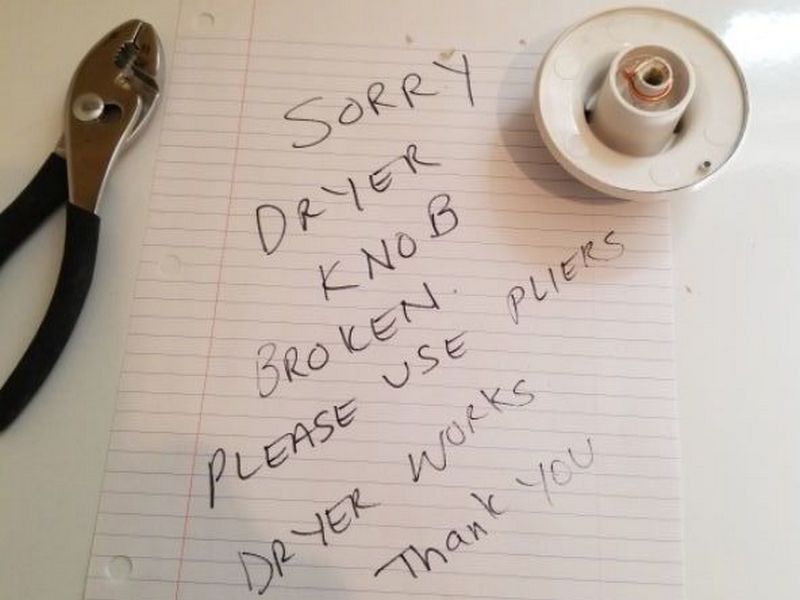

The range/oven has one or more damaged or missing control knobs. This affects proper function. Replace the control knobs.

The range/oven has one or more missing racks. This affects normal use. Replace the racks.

Range/Oven Limitation and Information Statements

Pilot light off, no operation: The pilot light is off, which prevents system operation and limits the inspection.

In use, not inspected: The range/oven is in use and, therefore, is not inspected.

Near/at end useful life, budget for replacement: The range/oven is near or at the end of its useful life. We recommend establishing a budget to replace the range/oven.

Past end useful life, budget for replacement: The range/oven is past the end of its useful life. We recommend establishing a budget to replace the range/oven.

Oven

In the component “Oven” we are essentially inspecting the lower portion of a Range/Oven; just the compartment where the bake and broil elements are. Ovens are built into cabinets, often as double units. A separate Cooktop appliance must provide a burner surface for pots and pans. Ovens can be electric or gas. Electric cooking requires a 240 volt connection; gas models just need 120 volts.

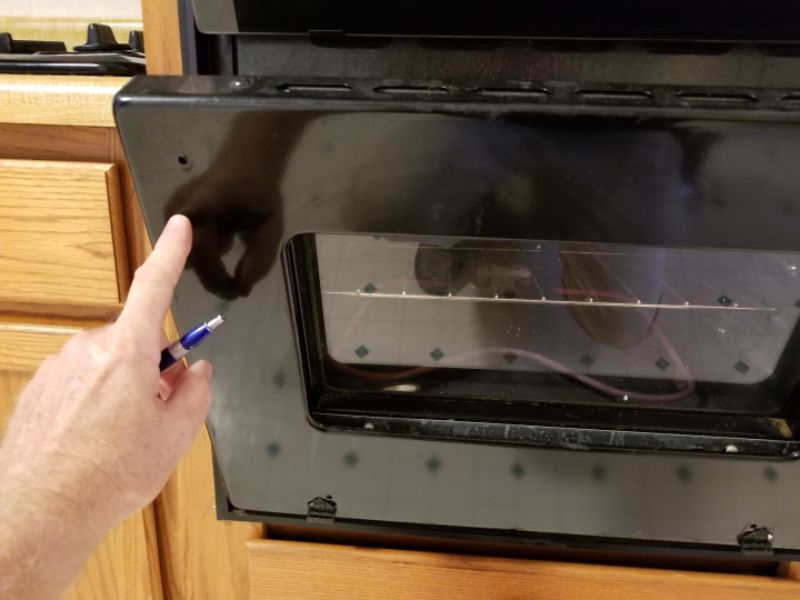

Ovens share many inspection concerns with the component “Range/Oven.” Safety and functionality are key. As a built-in appliance, ovens may not have the same anti-tip device as a free-standing unit, however they must be secure in the cabinet. This is a potential life safety issue. Always check inside the oven before testing it to ensure nothing’s in there, and never walk away from the appliance when an element is on. Assess the doors, door seals and handles, and convection fans when present (they may take a few minutes to start). Inspect for damage to a glass door, missing racks, and overall condition.

The oven is loose within its cabinet. This is a safety concern. Secure the oven.

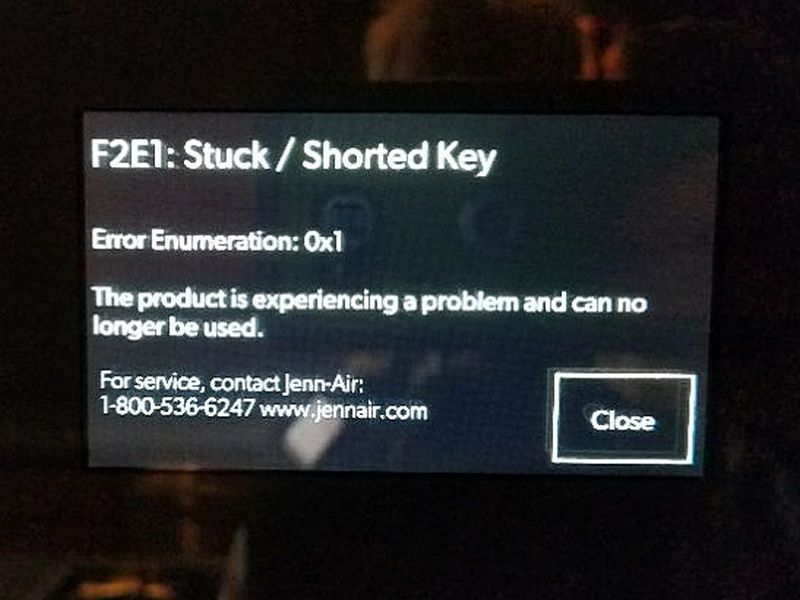

The oven has one or more inoperative elements. This affects proper function. Repair or replace the elements.

The oven is inoperative. This prevents normal use. Repair or replace the oven.

The oven door glass is cracked. This is a safety concern. Repair or replace the glass or door.

The oven’s convection fan does not turn on during operation. This affects proper operation. Repair or replace the fan.

The oven door is broken. This is a safety concern. Repair or replace the door.

The oven door seal has failed. This affects proper operation. Replace the door seal.

The oven door springs are broken. This is a safety concern. Repair or replace the springs.

The oven door handle is broken or missing. This is a safety concern. Repair or replace the door handle.

The oven has significant interior damage or corrosion. This is a safety and reliability concern. Replace the oven.

The oven has one or more damaged or missing control knobs. This affects proper function. Replace the control knobs.

The oven has one or more missing racks. This affects normal use. Replace the racks.

Oven Limitation and Information Statements

Pilot light off, no operation: The pilot light is off, which prevents system operation and limits the inspection.

In use, not inspected: The oven is in use and, therefore, is not inspected.

Near/at end useful life, budget for replacement: The oven is near or at the end of its useful life. We recommend establishing a budget to replace the oven.

Past end useful life, budget for replacement: The oven is past the end of its useful life. We recommend establishing a budget to replace the oven.

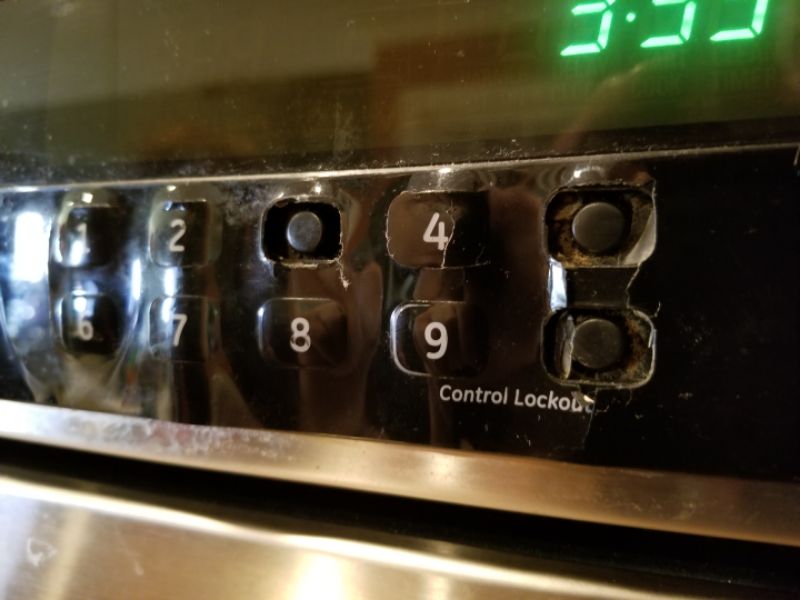

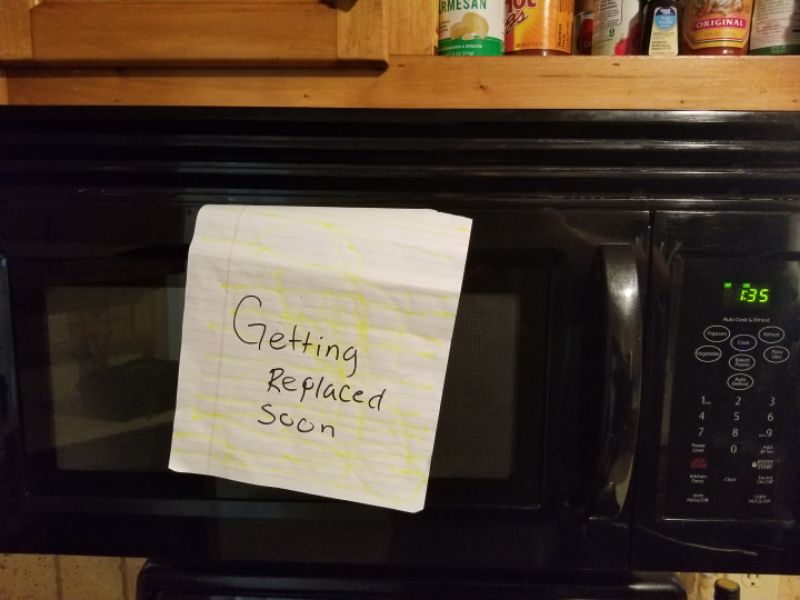

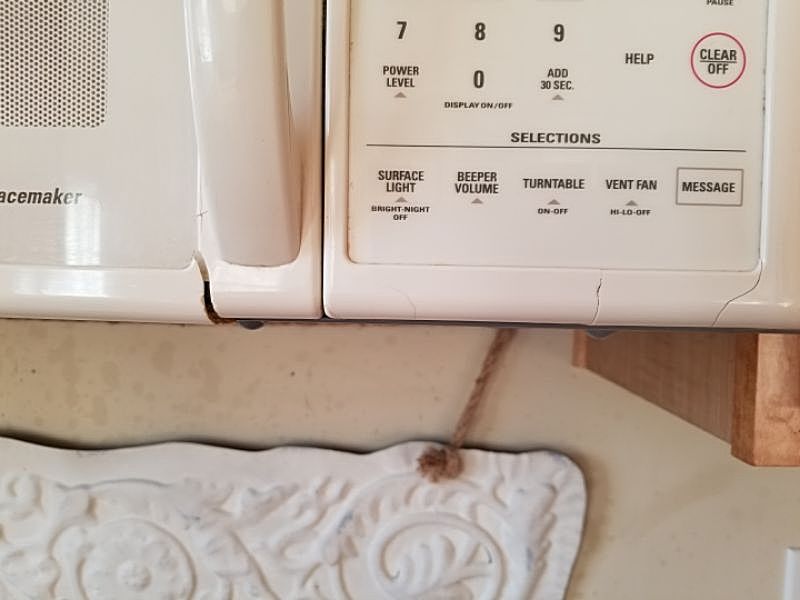

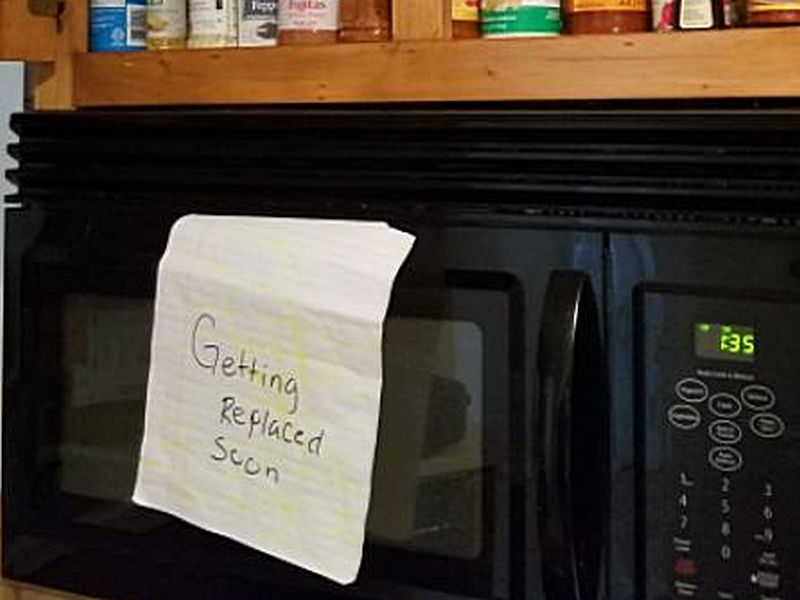

Microwave

Microwave ovens, once an expensive novelty, are now found in most kitchens. Microwaves are a form of electromagnetic energy. It passes through the food and is readily absorbed by water, sugar, and fat molecules, causing them to vibrate. This increased molecular activity is basically how we define heat! That’s why people say a microwave oven cooks things “from the inside.” The radiation is reflected by metal. This is why metal containers shouldn’t used, and why the oven’s walls are metal: it reflects the microwaves and keeps them safely inside.

Never run a microwave oven when empty, as this can damage it. You can test using a dampened paper towel or a small cup of water. Within 15-20 seconds the water should boil or the towel start to steam. Always report any arcing. Inspect for any physical damage inside and outside, including the door’s grid screen. The door should open easily and close tightly. If the unit is mounted it must be secure. If above a cooking surface a minimum 18″ clearance is needed. Check for functioning fans, lights, and turntables as present. Fans should not cause air to blow out around the cabinets; that implies a duct leak.

The microwave oven is inoperative. This prevents normal use. Repair or replace the oven.

The microwave oven is arcing during operation. This is a safety hazard. Replace the oven.

The microwave has significant interior damage or corrosion. This is a safety concern. Replace the oven.

The microwave door is broken or inoperative. This is a safety concern. Repair or replace the door.

The microwave door handle is broken or missing. This affects proper operation. Repair or replace the door handle.

The microwave has one or more missing, damaged, or inoperative controls. This affects proper function. Repair or replace the oven.

The microwave mounting is not secure. This is a safety concern. Secure the oven.

The space between the bottom of the microwave and the cooking surface is inadequate. This is a safety concern. Reinstall the oven so the space between the bottom of the oven and the cooking surface meets the manufacturer’s guidelines.

Microwave Limitation and Information Statements

In use, not inspected: The microwave oven is in use and, therefore, is not inspected.

Near/at end useful life, budget for replacement: The microwave is near or at the end of its useful life. We recommend establishing a budget to replace the microwave.

Past end useful life, budget for replacement: The microwave is past the end of its useful life. We recommend establishing a budget to replace the microwave.

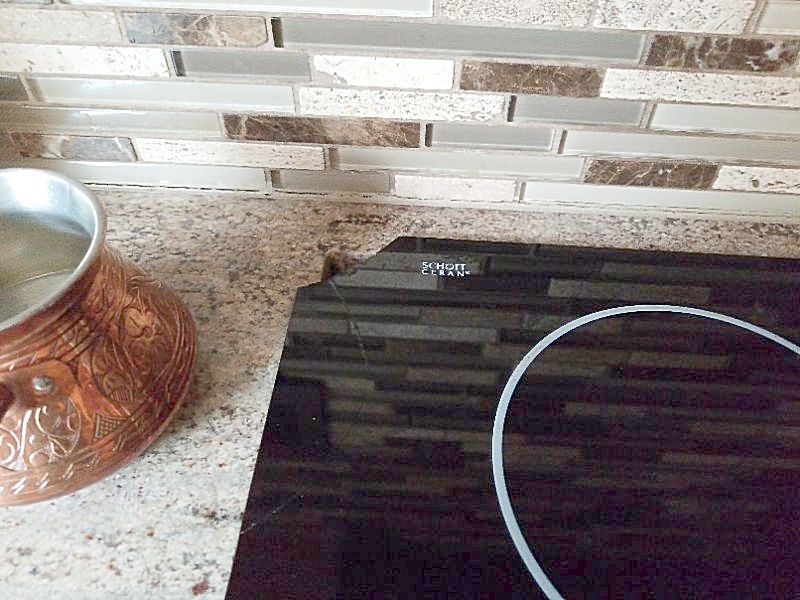

Cooktop

The component “Cooktop” is really just the upper burner section of a Range/Oven. As they are installed into a countertop, it’s little different from a drop-in range/oven minus the oven section. They can be electric or gas. Electric models require a 240 volt connection; gas just needs 120 volts as most newer units have electronic ignition rather than standing pilot lights.

Cooktops share many inspection concerns with Range/Ovens. Safety and functionality are key. They must be securely mounted. If a gas model, a shut-off valve must be accessible in the cabinet below. Electrical connections have to be properly installed in a junction box. Never walk away from the appliance when operating the burners. Assess any integral exhaust fans and report defects there in the component “Appliances – Ventilation Systems.” Inspect for damage to a glass cooktop, missing cooktop pan racks, burner functionality, and overall condition.

There are one or more inoperative burners. This affects proper function. Replace the burners.

The cooktop is inoperative. This prevents normal use. Repair or replace the cooktop.

The cooktop glass is broken. This affects proper operation and is a safety concern. Replace the glass.

There are one or more damaged or missing control knobs. This affects proper operation. Replace the control knobs.

Cooktop Limitation and Information Statements

Near/at end useful life, budget for replacement: The cooktop is near or at the end of its useful life. We recommend establishing a budget to replace the cooktop.

Past end useful life, budget for replacement: The cooktop is past the end of its useful life. We recommend establishing a budget to replace the cooktop.

Garbage Disposal

The United States is the global leader in the use of garbage disposals. About 50% of homes have one, compared to 3-5% in Canada. Historically, they have been prohibited in many localities. New York City only rescinded its ban on them in 1997. Their environmental impact is debatable. Food waste can be problematic in landfills. Its high water content means it take more energy to burn it in a waste-to-energy plant than it creates. Overall, a disposal’s low energy usage is balanced out by the useful biogas contribution the food waste provides to well-managed sewage treatment plants. As inspectors, we want to ensure that the garbage in the disposal keeps flowing away without any concerns.

The more powerful a disposal is, and the more stainless steel in its construction, the longer it will last. Inspect for a smooth, quiet operation and for any signs of leaking. Look inside with your flashlight for significant corrosion. The rubber splash guard must be in place at the sink drain for safety. Additionally, power switches should not be placed on the cabinet’s front surface or toe kick where they can inadvertently be pressed and turn on the appliance.

The garbage disposal is leaking. This can cause water damage. Replacement may be required. Replace the disposal.

Debris is present in the garbage disposal. It does not function as intended. The debris may have caused damage to the inside of the unit. Clean the disposal. Replace the appliance as needed.

The garbage disposal’s rubber splash guard is missing. This is a safety concern. Install a splash guard.

The garbage disposal is excessively corroded. This indicates a failing and unreliable appliance. Replace the disposal.

The garbage disposal’s power switch is in an unsafe location. It can be accidentally turned on while working at the counter. Hire an electrician to relocate the power switch to a safe and appropriate location.

Garbage Disposal Limitation and Information Statements

Near/at end useful life, budget for replacement: The garbage disposal is near or at the end of its useful life. We recommend establishing a budget to replace the garbage disposal.

Past end useful life, budget for replacement: The garbage disposal is past the end of its useful life. We recommend establishing a budget to replace the garbage disposal.

Garbage disposal includes a reset button, push button if garbage disposal becomes inoperative: The garbage disposal includes a reset button. Push the reset button if the garbage disposal becomes inoperative.

House served by private septic system and garbage disposal unit, combo not recommended, some local jurisdictions prohibit combo: The house is served by a private septic waste disposal system and a garbage disposal unit. This combination is not recommended because the garbage disposal produces more insoluble solid waste than is advised for a septic system. Some local jurisdictions prohibit this combination.

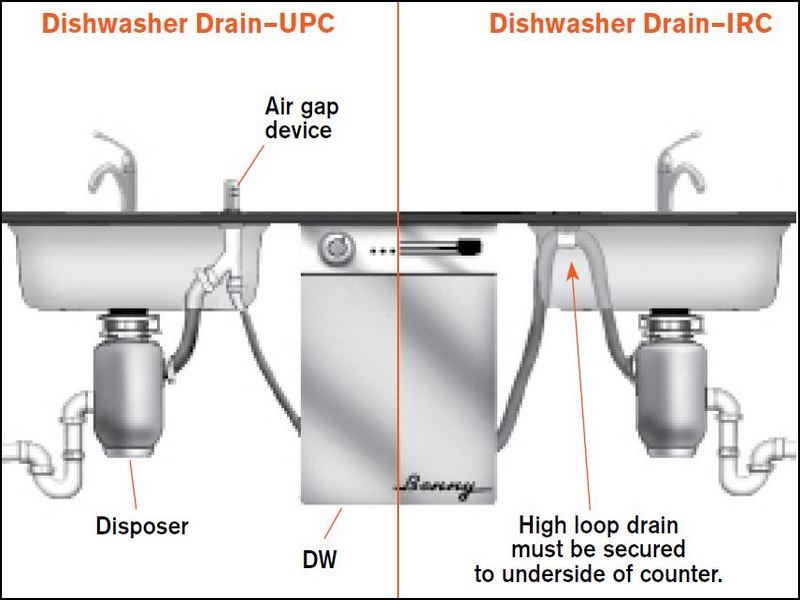

Dishwasher

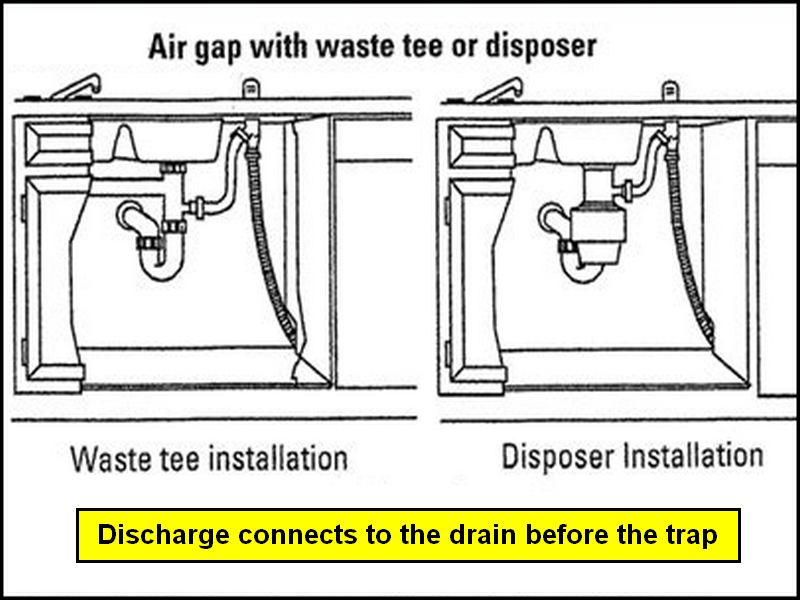

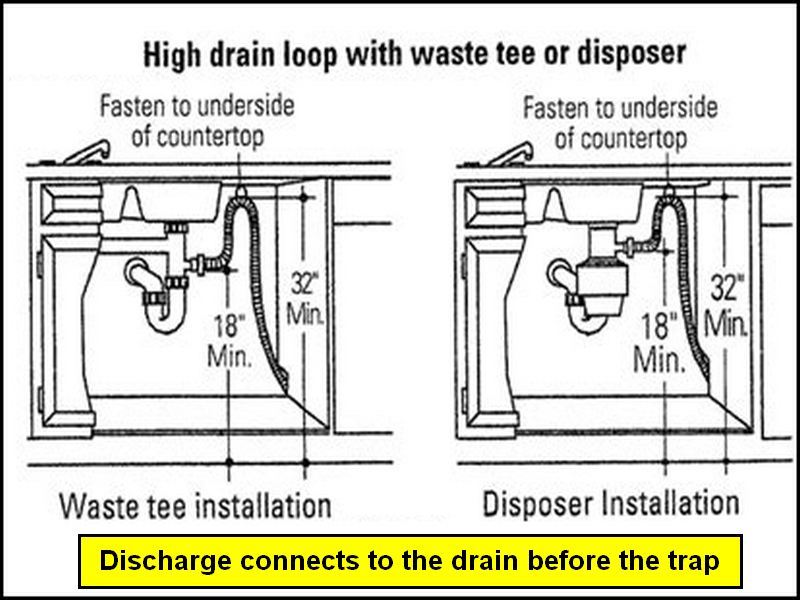

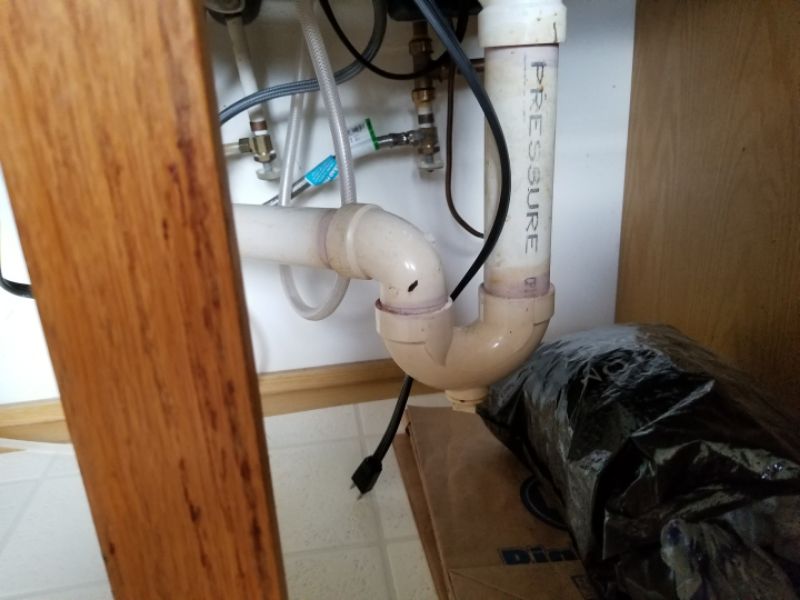

Well over 75% of homes in this country have a dishwasher. Regardless, most homeowners are unaware of the damage and health risks they can cause. Leaks are the more obvious concern, but the problem may not be readily visible. The lack of a properly-installed air gap or “high loop” on the discharge is the #1 defect. It can allow drain waste to contaminate the dishwasher. You must know which rules apply in your area. Connecting the appliance to the cold water supply is unsanitary. A secure, level installation is required, as well as full functionality.

Inspect for an air gap device or a high loop. The dishwasher’s built-in drain hose loop or a garbage disposer are not a substitute. High loops must be secured at the underside of the countertop. The discharge hose must connect to the drain before the trap. The appliance should be secured to the countertop or cabinet so it can’t tip or shift. Check the interior and close the soap dish before operating it. Do this first when inspecting the kitchen so you can watch for leaks: check back frequently. Did the soap dish open and the unit drain? Is there any damage apparent? Check the basement or crawlspace for water damage underneath.

You must know which rules apply in your area

Air Gap installation

Air Gaps should be installed to drain into the sink if a blockage occurs

“High Loop” installation

The dishwasher does not have an anti-siphon device on the drain line. An air gap or a “high loop” in the drain line prevents wastewater from entering the dishwasher and water supply. Install a “high loop” or an anti-siphon device.

The dishwasher leaks. This affects proper operation and can cause damage. Repair or replace the dishwasher.

The dishwasher does not drain properly during a complete cycle. This affects proper function and can be a health concern. Repair or replace the dishwasher.

The dishwasher discharge backs up into the sink. This implies a partially clogged drain or improper installation of the dishwasher discharge pipe. Hire a plumber for an evaluation and to make repairs as needed.

The dishwasher is plumbed to the cold water supply. This is a sanitary and health risk. Dishwashers must be supplied by hot water. Hire a plumber to connect the dishwasher to the hot water supply.

The dishwasher is not properly secured to the cabinet or the countertop. This is a safety hazard. Secure the dishwasher.

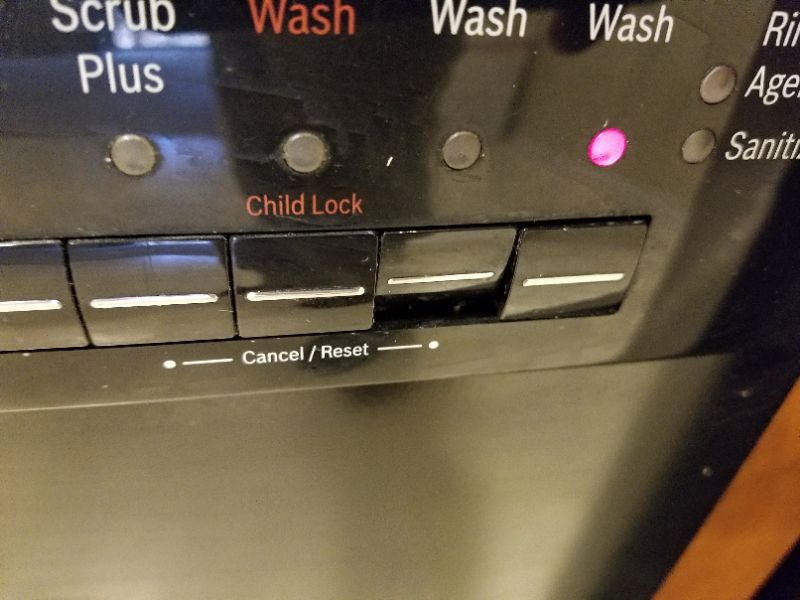

The dishwasher is inoperative. This prevents normal use. Repair or replace the dishwasher.

The dishwasher controls are broken. This affects proper function. Replace the controls.

The dishwasher’s soap dispenser does not operate properly. This is a safety concern that prevents adequate cleaning. Hire a contractor for repairs as needed.

The dishwasher door springs are inoperative. This is a safety concern. Replace the springs.

The dishwasher door does not close properly. This affects proper operation and can allow leaks. Repair or replace the door or replace the dishwasher.

The dishwasher racks are damaged or missing. This affects proper operation. Replace the racks.

The dishwasher isn’t level. This can affect proper operation, and can cause loose connections and leaks. Level the dishwasher.

Dishwasher Limitation and Information Statements

In use, not inspected: The dishwasher is in use and, therefore, is not inspected.

Water service to dishwasher is off, visual inspection: Water service to the dishwasher is not turned on; we do not operate shut-off valves. Therefore, portions of the appliance which require water for operation are visually inspected only.

Near/at end useful life, budget for replacement: The dishwasher is near or at the end of its useful life. We recommend establishing a budget to replace the dishwasher.

Past end useful life, budget for replacement: The dishwasher is past the end of its useful life. We recommend establishing a budget to replace the dishwasher.

Air gap device located on top of kitchen counter/or high loop installed under sink, prevents possibility of back-siphoning non-potable water into dishwasher: The dishwasher air gap is a device located on top of the kitchen counter by the sink or a high loop installed under the kitchen sink. The purpose of an air gap is to prevent the possibility of back siphoning non-potable water from the dishwasher.

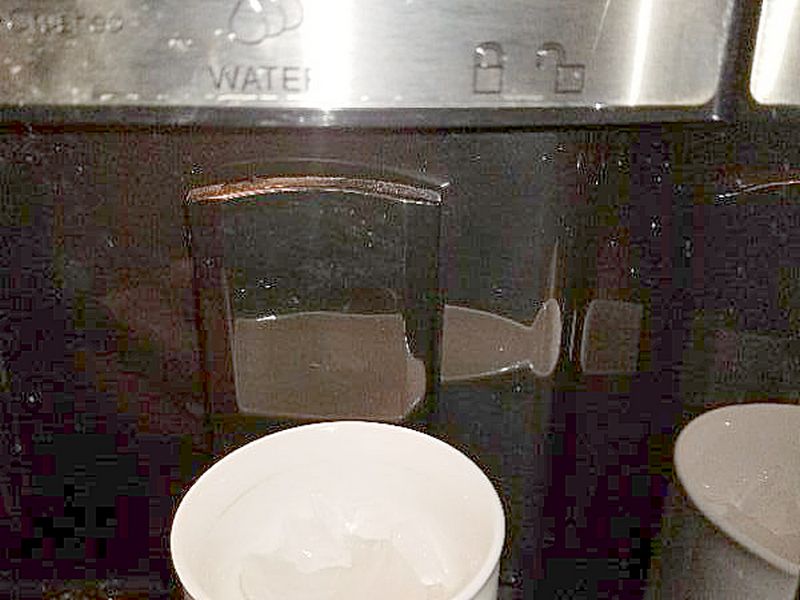

Refrigerator/Freezer

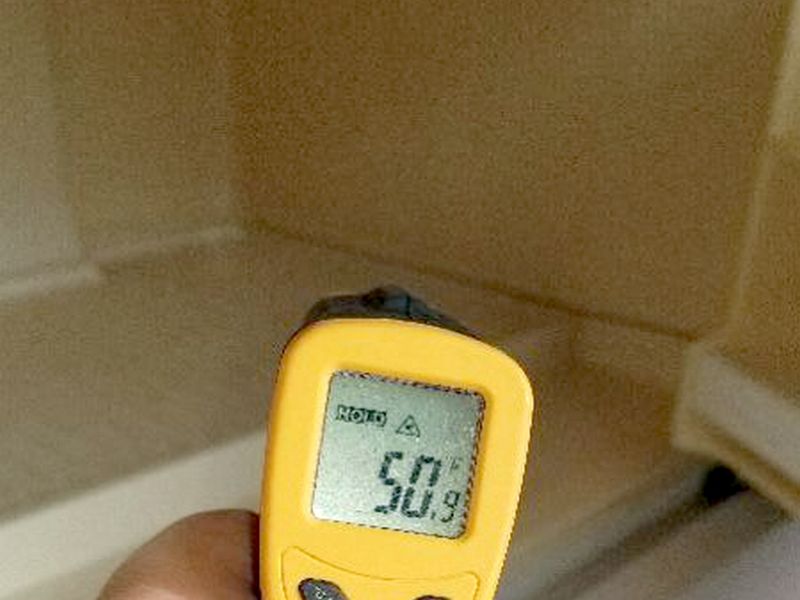

Imagine if you built a small room, and made it very tight and super-insulated. If you add sufficient air conditioning to drive the interior temperature below freezing, you’ve just made a walk-in freezer! That’s basically what your home’s refrigerator/freezer is. Remember: AC units don’t “make cold”, they remove heat. That happens in the freezer section. The cold air there is pumped by a fan into the refrigerator compartment and regulated to an appropriate temperature. Modern refrigerator/freezers aren’t just dark, cold boxes. They often dispense water and ice, have filters, racks, slide-outs, and multiple sections. We need to look at all of this in addition to just making sure everything’s cold enough.

Use your IR camera or thermometer to check the appliance’s temperatures. The refrigerator section must be between 34° F. and 40° F. The freezer should be well below freezing; at or near 0° F is recommended. Check all ice and water dispensing functions, and look carefully for leaks. Door seals must be in good condition to maintain temperatures. Cabinet-mounted models must be secure. All refrigerator/freezers should be on a dedicated circuit.

The refrigerator is inoperative. This prevents normal use. Repair or replace the refrigerator as needed.

The refrigerator ice-maker is not working properly. This affects normal use. Repair or replace the ice-maker.

The refrigerator water dispenser is not working properly. This affects normal use. Repair or replace the water dispenser.

The refrigerator water supply is leaking. This can cause damage. Repair or replace the refrigerator as needed.

The refrigerator door gasket is worn or damaged. The temperature may be prone to fluctuations. This affects proper function. Replace the gasket.

The refrigerator has damaged interior components. This affects proper function. Repair or replace the refrigerator as needed.

The refrigerator door handle is broken or missing. This affects proper function. Replace the door handle.

Refrigerator/Freezer Limitation and Information Statements

Water service to refrigerator/freezer is off, visual inspection: Water service to the refrigerator/freezer is not turned on; we do not operate shut-off valves. Therefore, portions of the appliance which require water for operation are visually inspected only.

Near/at end useful life, budget for replacement: The refrigerator/freezer is near or at the end of its useful life. We recommend establishing a budget to replace the refrigerator/freezer.

Past end useful life, budget for replacement: The refrigerator/freezer is past the end of its useful life. We recommend establishing a budget to replace the refrigerator/freezer.

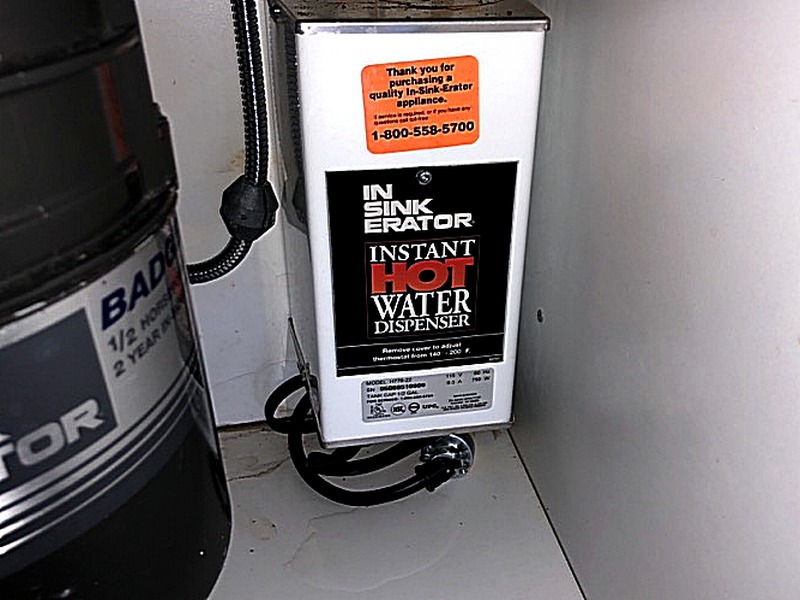

Other Built-ins

The component “Other Built-ins” includes free-standing ice-makers, wine coolers, instant hot water dispensers, and trash compactors. We will also look briefly at central vacuum systems. Wine coolers are basically specialized refrigerators. Instant hot water dispensers provide near-boiling water on demand. Trash compactors, while waning in popularity, do exactly what their name implies. Free-standing ice-makers are usually under-counter appliances.

Most free-standing ice-makers don’t actually keep the ice fully frozen. This saves energy, produces ice faster, makes scooping easier, and prevents the ice from clumping into ball in a drink. It also means the ice is constantly melting, hence a drain system is needed; check for leaks. Wine coolers are inspected much the same as a refrigerator. Instant hot water dispensers have a sink-top spigot. They must be checked for function as well as leaks and wiring defects in the cabinet below. Trash compactors shouldn’t operate until the door is fully closed and latched. Check inside before testing. We only check central vacuum outlets, not hoses and attachments.

The ice-maker is inoperative. This prevents normal use. Repair or replace the ice-maker.

The wine cooler is inoperative. This prevents normal use. Repair or replace the wine cooler.

The wine cooler door or door handle is defective. This affects proper operation. Repair or replace the door or handle.

The instant hot water device is inoperative. This prevents normal use. Repair or replace the instant hot water device.

The instant hot water system leaks. This can cause damage. Repair or replace the instant hot water device.

The trash compactor is inoperative. This prevents normal use. Repair or replace the trash compactor.

The central vacuum system is inoperative. The reason for this is not known. Hire a contractor for repairs or replacement as needed.

The central vacuum system’s port is damaged or inoperative. This affects proper function and can reduce the overall suction. Hire a contractor for repairs as needed.

Other Built-ins Limitation and Information Statements

Near/at end useful life, budget for replacement: The appliance is near or at the end of its useful life. We recommend establishing a budget to replace the built-in appliance.

Past end useful life, budget for replacement: The appliance is past the end of its useful life. We recommend establishing a budget to replace the built-in appliance.

Ventilation System

“Appliances – Ventilation System” includes two somewhat different sub-components. Exhaust fans, in this case kitchen ventilators, move stale air, cooking smoke, and excess moisture out of the home. This is essential for safety and a healthy indoor environment. Equally important are dryer vent systems, notably the transition and exhaust ducts, and their terminations. These carry lint-filled, warm, moist air out of the house. This has both health and safety implications. Dryer venting has been provided here, as well as in the component “Appliances – Dryer” to enable reporting on concerns with the ducts when a dryer is not present.

Exhaust fans and dryer venting should always discharge to the exterior of the home. The attic, crawlspace, wall cavity, and garage are not appropriate. An effort must be made to identify the termination, which can be tricky. Exhaust fans that vent inside can cause grease build-up, condensation, mold, and mildew. Dryers must be able to freely discharge outdoors. Any configuration that causes lint build-up is a fire hazard. Vent hoods must be in good condition and free of screening. Maximum effective duct length limits must be observed.

The exhaust fan is inoperative. This prevents normal use. Repair or replace the exhaust fan.

The exhaust fan terminates into the attic, which creates moisture in the attic, and may cause mold and mildew problems. This is also a fire hazard. Reroute the fan to the exterior.

The exhaust fan terminates in the garage, which creates moisture inside the garage. This is a fire hazard. The exhaust fan also creates a path for exhaust fumes, smoke, or fire to enter the house. Reroute the fan to the exterior.

The exhaust fan terminates into the crawl space, which creates moisture in the crawl space, and may cause molds and mildew problems. This is also a fire hazard. Reroute the fan to the exterior.

The exhaust fan filter is missing. This is a safety concern. Replace the filter.

The exhaust fan is dirty. Dirt and grease build-up are fire hazards. Clean the exhaust fan.

The exhaust fan vent pipe material is not recommended for kitchen exhausting applications. This is a fire hazard. Replace the pipe.

The exhaust fan controls are broken or missing. This affects proper operation. Repair or replace the controls.

The exhaust fan exterior cover is damaged or missing. This is a safety concern. Repair or replace the cover.

The exhaust fan damper is missing or inoperative. This allows exterior air to enter. Repair or replace the damper.

The dryer’s vent pipe has excessive lint buildup. This is a fire hazard. Clean the vent pipe.

The dryer’s vent is an improper material. This is a fire hazard. Replace the vent.

The dryer’s vent terminates inside the house. This creates moisture in the house and may cause mold or mildew problems. It is a fire hazard. Reroute the vent to the exterior.

The dryer’s vent terminates into the crawl space. This creates moisture inside the crawl space and may cause mold or mildew problems. It is a fire hazard. Reroute the vent to the exterior.

The dryer’s vent terminates into the attic. This creates moisture inside the attic and may cause mold or mildew problems. It is a fire hazard. Reroute the vent to the exterior.

The dryer’s vent exterior hood is damaged or missing. This is a safety hazard. Repair or replace the exterior hood.

The dryer’s vent exterior hood is screened. This is improper as it can cause lint build-up and create a fire hazard. Remove the screen.

The dryer’s vent pipe is damaged. It will not provide adequate venting and can trap lint within it. This is a fire hazard. Replace the vent pipe.

The dryer’s vent pipe has screws connecting the sections together. This can lead to buildup and clogging, which is a fire hazard. Repair or replace the vent pipe ensuring that the sections are taped together using a properly-rated product.

The dryer’s vent pipe sags, which will allow condensation and lint to collect and block the air flow. This is a safety concern and a fire hazard. Replace the vent pipe.

The dryer’s vent pipe is disconnected. This permits moisture inside of the house as well as possible pest intrusion. Connect the vent pipe.

The dryer’s vent is missing insulation where the duct passes through unconditioned spaces. This can lead to condensation on the inside of the vent and can allow ice to form and obstruct the vent. Install insulation.

The dryer’s vent pipe is too long; vent pipes should not 35 calculated feet. Warm, moist air can condense inside the pipe and block proper exhaust. This is a safety concern. Replace and re-route the vent pipe.

Ventilation System Limitation and Information Statements

Near/at end useful life, budget for replacement: The exhaust fan is near or at the end of its useful life. We recommend establishing a budget to replace the exhaust fan.

Past end useful life, budget for replacement: The exhaust fan is past the end of its useful life. We recommend establishing a budget to replace the exhaust fan.

Exhaust fan is recirculating, clean the filter at regular intervals: The exhaust fan is a recirculating type, i.e., the fan does not vent to the exterior. Clean the filter at regular intervals.

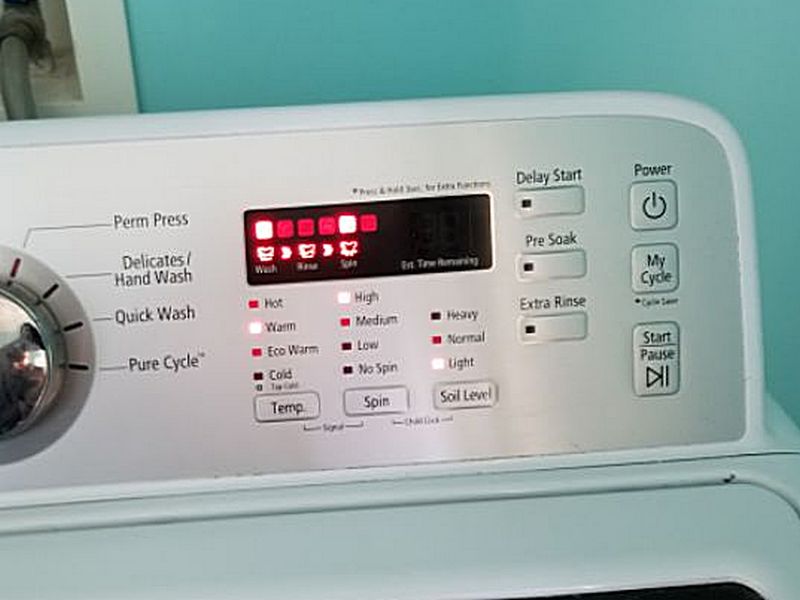

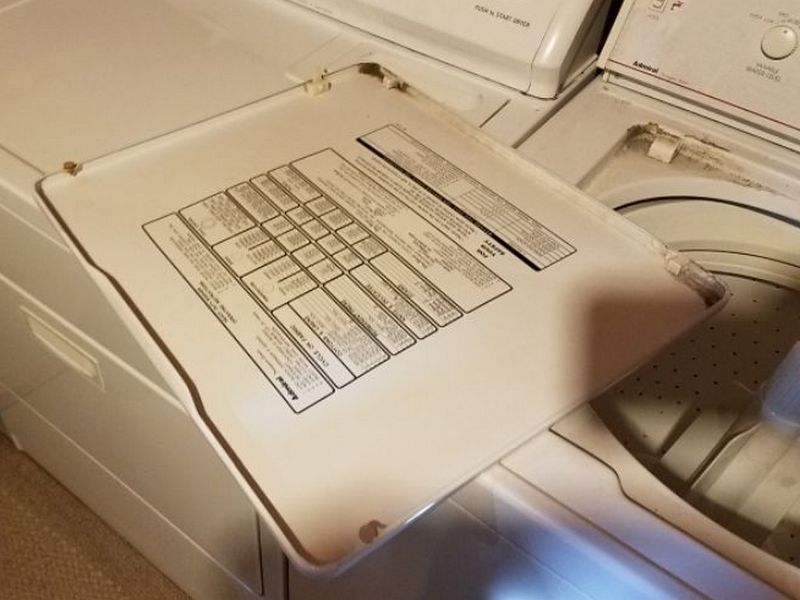

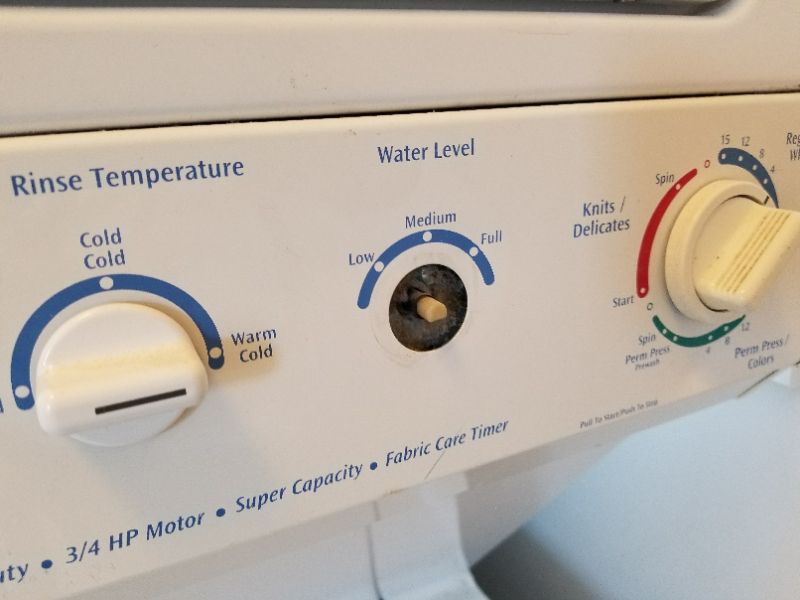

Washer

Clothes washers are very high on the list of modern appliances the average person considers essential. They may do without a dishwasher. But even if you have to go to a laundromat, washing the family’s clothes by hand is not something most folks would even think about. Our job is not to evaluate how well a washer cleans clothes; we are concerned with basic functionality. Additionally, as this is an appliance that uses gallons of water in each cycle, we must look at features that help prevent water damage.

We never operate a washer unless we can ensure that a drain hose is securely attached to the machine and to the drain stand. This is to prevent major flooding. If this cannot be confirmed, do not operate the washer: report it as “Not Inspected” and state why. A washer should operate quietly and without excess vibration or movement. Take a photo of the washer filling to show that it was operated. The tub should drain completely. Inspect for damage. Any washer on or above a finished level should have an intact catch pan with a drain. If a washer isn’t present, best practice is to use a length of hose to test the laundry drain, and take a photo.

The washing machine is inoperative. This prevents normal use. Repair or replace the washing machine.

The washing machine is leaking. This can cause damage. Repair or replace the washing machine.

The washing machine is damaged. This affects reliability and function. Repair or replace the washer.

The washing machine controls are broken. This affects proper operation. Replace the controls.

The washing machine is rusted or corroded. This implies an unreliable appliance and a limited remaining service life. Repair or replace the washing machine.

Water flow to the washing machine is insufficient. Typically, this indicates clogged filters or screens at the inlet hoses, or a malfunctioning solenoid valve. Clean the screens. If this does not solve the problem, hire a contractor for repairs or replacement as needed.

The washing machine’s door shut-off sensor is broken. The washer continues to run when the door is opened. This is a safety concern. Repair or replace the sensor.

Transmission fluid is leaking from the washing machine. This implies a problem that can further damage the washer. Repair or replace the washing machine.

The washing machine does not have a drip pan. Washers on or above finished areas should be installed on a draining catch pan to prevent water damage if the appliance leaks. Install a draining drip pan.

The pan under the washing machine is damaged. Washers on or above finished areas should be installed on a draining catch pan to prevent water damage if the appliance leaks. Replace the drip pan.

The drain pan under the washing machine is not connected to a drain line. Washers on or above finished areas should be installed on a draining catch pan to prevent water damage if the appliance leaks. Connect the pan to a proper drain line.

The washing machine’s drain pipe discharges to the exterior. Draining gray water to other than a proper drain/waste disposal system is improper and may lead to unsanitary conditions. Hire a plumber for repairs as needed.

The washing machine drains into a sump served by a pump made for water control. This is inappropriate as the pump is not designed to handle the “gray water” discharge of a clothes washer. Hire a plumber for repairs as needed.

The washing machine drain standpipe lacks a trap. This may allow sewage gases to vent into the interior of the dwelling. Hire a plumber for repairs as needed.

The drain line for the washing machine does not have an “air break” as required by accepted practice. This risks recycling and siphoning waste water. Hire a plumber for repairs as needed.

Washer Limitation and Information Statements

In use, not inspected: The washer is in use and, therefore, is not inspected.

Water service to washing machine is off, visual inspection: Water service to the washing machine is not turned on; we do not operate shut-off valves. Therefore, portions of the appliance which require water for operation are visually inspected only.

Not inspected/operated, outside scope of inspection: The washing machine is not inspected or operated as it is outside the scope of a Home Inspection.

Near/at end useful life, budget for replacement: The washer is near or at the end of its useful life. We recommend establishing a budget to replace the washer.

Past end useful life, budget for replacement: The washer is past the end of its useful life. We recommend establishing a budget to replace the washer.

Drain for catch pan under not visible, confirm that pan is connected and sealed to a drain line, pans should drain to exterior: The drain for the catch pan under the washing machine is not visible. We recommend that you confirm that the pan is connected and sealed to a drain line. Pans used as the only leak control measure should drain to the exterior.

Connects to water supply using rubber hoses, recommend upgrade to metal-mesh clad hoses: The washing machine connects to the water supply using rubber hoses. These are considered unreliable because rubber hoses tend to weaken with age, bulge, and burst causing flooding. We recommend upgrading to metal-mesh clad hoses.

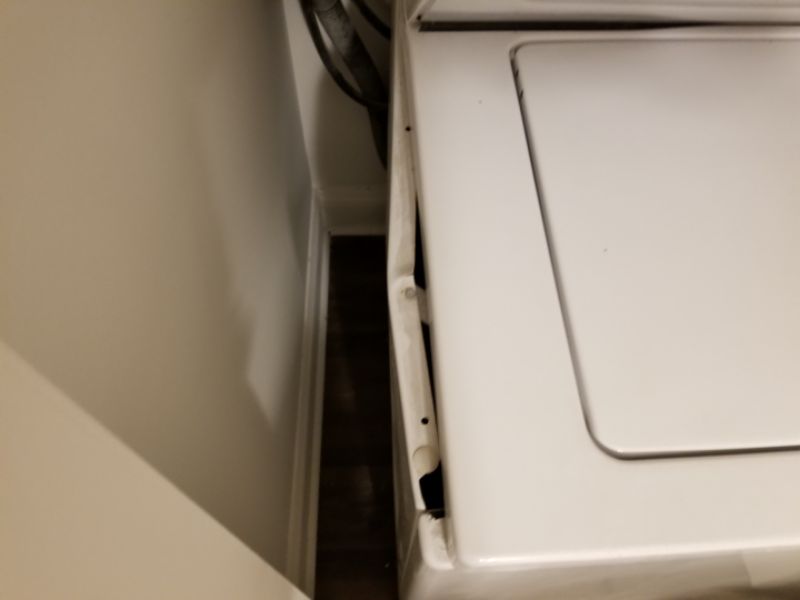

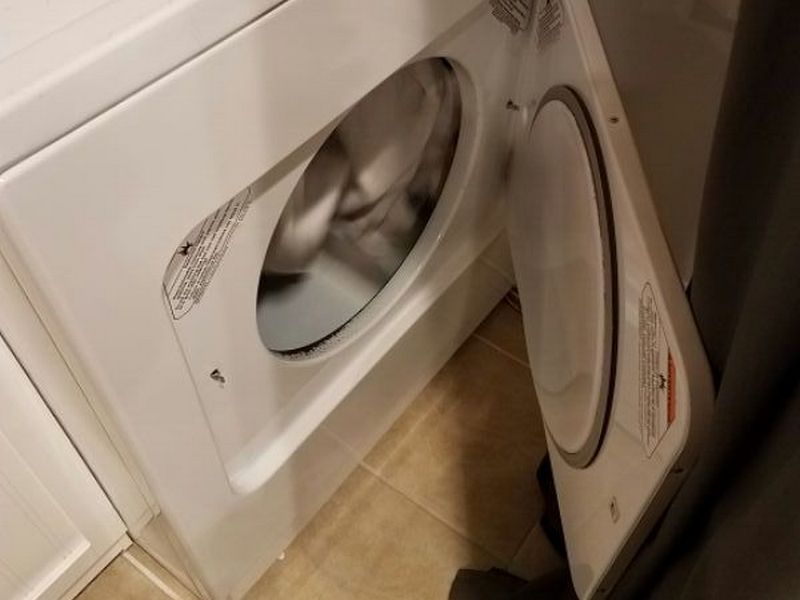

Dryer

The large majority of clothes dryers in this country are basic affairs. Called tumble dryers, they have a rotating drum. Ambient air is drawn in, heated, and passed over the wet clothes as they “tumble” about in the drum, driving out the moisture. The resulting hot, humid air is vented from the machine. This is fairly wasteful. However, they are simple and reliable, and hence, very popular. There are other systems, including heat pump dryers, centrifugal spin units, convective, condenser, microwave, and ultrasonic dryers. These are rare in our work at this time, and we won’t cover them.

As with washers, we focus on functionality. Does it heat? Is the operation smooth and quiet? Inspect for damage, including a door interlock. Additionally, safety is a concern, specifically with the venting. Over 5,000 house fires annually are attributed to improper dryer venting. Dryers must be able to freely discharge outdoors. Any configuration that causes lint build-up is a fire hazard. Vent hoods must be in good condition and free of screening. Maximum effective duct length limits must be observed.

The dryer is inoperative. This prevents normal use. Repair or replace the dryer.

The dryer is damaged. This affects normal use and can be a safety hazard. Repair or replace the dryer.

The dryer’s controls are broken. This affects proper operation. Replace the controls.

The dryer’s door shut-off sensor is broken. The dryer continues to run when the door is opened. This is a safety concern. Repair or replace the sensor.

The dryer’s lint screen is damaged or missing. This is a safety concern. Replace the lint screen.

The clothes dryer appears to be overheating. This is a safety hazard. Repair or replace the dryer.

The dryer’s vent pipe has excessive lint buildup. This is a fire hazard. Clean the vent pipe.

The dryer’s vent is an improper material. This is a fire hazard. Replace the vent.

The dryer’s vent terminates inside the house. This creates moisture in the house and may cause mold or mildew problems. It is a fire hazard. Reroute the vent to the exterior.

The dryer’s vent terminates into the crawl space. This creates moisture inside the crawl space and may cause mold or mildew problems. It is a fire hazard. Reroute the vent to the exterior.

The dryer’s vent terminates into the attic. This creates moisture inside the attic and may cause mold or mildew problems. It is a fire hazard. Reroute the vent to the exterior.

The dryer’s vent exterior hood is damaged or missing. This is a safety hazard. Repair or replace the exterior hood.

The dryer’s vent exterior hood is screened. This is improper as it can cause lint build-up and create a fire hazard. Remove the screen.

The dryer’s vent pipe is damaged. It will not provide adequate venting and can trap lint within it. This is a fire hazard. Replace the vent pipe.

The dryer’s vent pipe has screws connecting the sections together. This can lead to buildup and clogging, which is a fire hazard. Repair or replace the vent pipe ensuring that the sections are taped together using a properly-rated product.

The dryer’s vent pipe sags, which will allow condensation and lint to collect and block the air flow. This is a safety concern and a fire hazard. Replace the vent pipe.

The dryer’s vent pipe is disconnected. This permits moisture inside of the house as well as possible pest intrusion. Connect the vent pipe.

The dryer’s vent is missing insulation where the duct passes through unconditioned spaces. This can lead to condensation on the inside of the vent and can allow ice to form and obstruct the vent. Install insulation.

The dryer’s vent pipe is too long; vent pipes should not 35 calculated feet. Warm, moist air can condense inside the pipe and block proper exhaust. This is a safety concern. Replace and re-route the vent pipe.

Dryer Limitation and Information Statements

Pilot light off, no operation: The pilot light is off, which prevents system operation and limits the inspection.

In use, not inspected: The dryer is in use and, therefore, is not inspected.

Not inspected/operated, outside scope of inspection: The dryer is not inspected or operated as it is outside the scope of a Home Inspection.

Near/at end useful life, budget for replacement: The dryer is near or at the end of its useful life. We recommend establishing a budget to replace the dryer.

Past end useful life, budget for replacement: The dryer is past the end of its useful life. We recommend establishing a budget to replace the dryer.

240V electrical receptacle and gas line hookup: There is a 240V electrical receptacle and gas line hookup for the dryer.

240V electrical receptacle, no gas line: There is a 240V electrical receptacle for the dryer. There is no gas line.

3-wire plug, check dryer to ensure connection is compatible: The laundry facility includes a 3-wire plug. Check your dryer to ensure that the connection is compatible.

4-wire plug, check dryer to ensure connection is compatible: The laundry facility includes a 4-wire plug. Check your dryer to ensure that the connection is compatible.

Gas line hookup, no 240V receptacle: There is a gas line hookup for the dryer. There is no 240V receptacle.