Purpose and Scope

The purpose of the Standards of Practice is to establish a minimum and uniform standard for US Inspect employees performing Home Inspections. Home Inspections performed to these Standards of Practice are intended to provide the client with objective information regarding the condition of the systems and components of the home as inspected at the time of the home inspection. Any state mandated inspection and/or reporting requirements in the market where the inspector is working will always take priority over the SOP documented here in case of a conflict. Redundancy in the description of the requirements, limitations, and exclusions regarding the scope of the Home Inspection is provided for emphasis only.

- Inspectors shall:

- Adhere to the widely accepted industry standard Code of Ethics for home inspectors in the performance of their duties.

- Ensure that they are fully familiar with the state-specific inspection and reporting standards that govern their market.

- Inspect the readily accessible, visually observable, installed systems and components listed in the Standards of Practice.

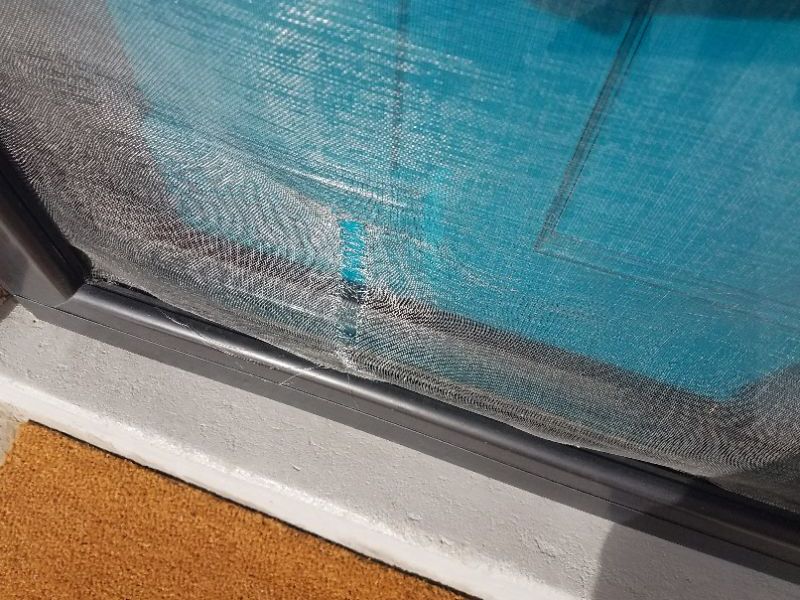

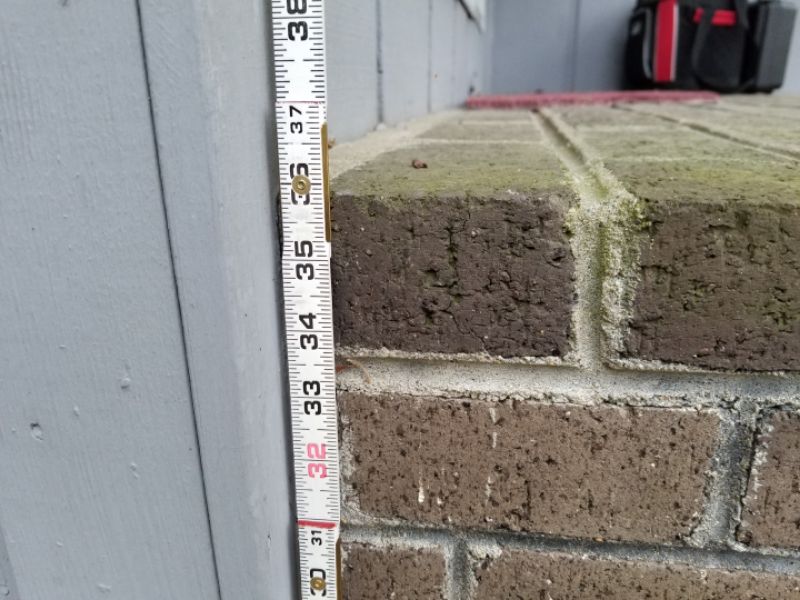

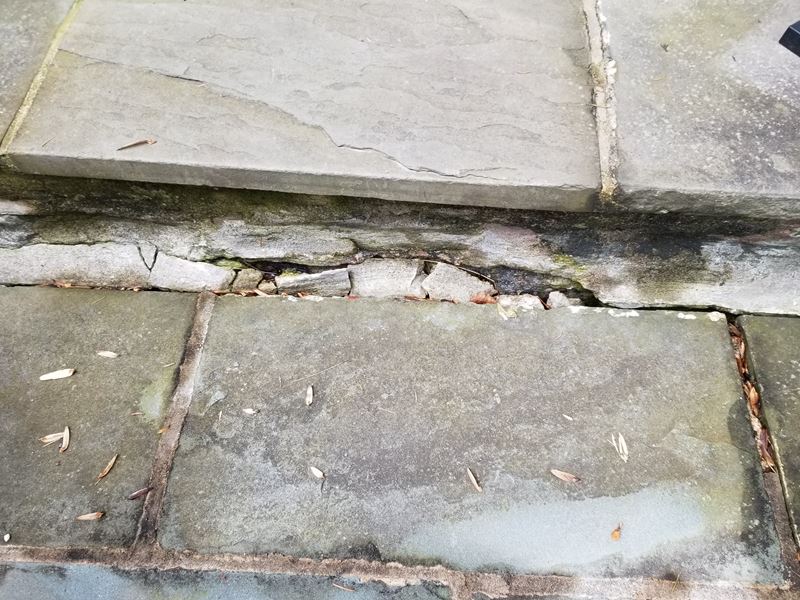

- Provide clear photographs of all systems, components, defects, and limitations as set forth in the US Inspect Field Procedures for Home Inspections.

- Report:

- Those system and components inspected that, in the professional judgment of the inspector, are not functioning properly, significantly deficient, unsafe, or are near the end of their service lives.

- Recommendations to correct, or monitor for future correction, the reported deficiencies, or items needing further evaluation. (Inspectors are NOT required to determine methods, materials, or costs of corrections.)

- Reasoning or explanation as to the nature and implications of the reported deficiencies that are not self-evident.

- Systems and components designated for inspection in these Standards of Practice that were present at the time of the home inspection but were not inspected and the reason(s) they were not inspected.

- The industry-accepted useful lifespan range for systems or materials.

- Standards of Practice aren’t intended to limit inspectors from:

- Including other inspection services or systems and components in addition to those required above.

- Designing or specifying repairs, provided the inspector is appropriately qualified and willing to do so.

- Excluding systems and components from the inspection if requested by the client.

General Limitations and Exclusions

- General Limitations:

- The inspector is NOT required to perform any action or make any determination(s) not specifically stated in these Standards of Practice.

- Inspections performed in accordance with these Standards of Practice:

- Are not technically exhaustive.

- Are not required to identify concealed conditions, latent defects, or consequential damage(s).

- These Standards of Practice apply to buildings with four or fewer dwelling units, their garages or carports, and those outbuildings included in the job order.

- General Exclusions:

- Inspectors are NOT required to:

- Offer or perform any act or service contrary to law.

- Offer or perform engineering services.

- Offer or perform any trade or any professional service other than a Home Inspection.

- Perform any procedure or operation that will, in the judgment of the inspector, likely be dangerous to the inspector or other persons, or damage the property or its systems or components.

- Describe or report on any system or component that is not included in these Standards that was not inspected.

- Move personal property, furniture, equipment, plants, soil, snow, ice, or debris.

- Dismantle any system or component, except as explicitly required by these Standards of Practice.

- The inspector is NOT required to determine:

- Conditions of systems or components that are not readily accessible.

- Strength, adequacy, effectiveness, or efficiency of any system or component.

- The causes of any condition or deficiency.

- Methods, materials, or costs of corrections, except for costs-to-cure in markets that require them.

- Future conditions including, but not limited to, the failure of systems and components.

- The suitability of the property for any specialized use.

- Compliance with regulatory requirements

- The market value of the property or its marketability.

- The advisability of purchase of the property.

- The presence of any environmental hazards including, but not limited to, toxins, carcinogens, noise, and contaminants in the soil, water, and air.

- The effectiveness of any system installed or any method utilized to control or remove suspected hazardous substances.

- The operating costs of systems or components.

- The acoustical properties of any system or component.

- Inspectors are NOT required to operate:

- Any system or component that is shut down or otherwise inoperable.

- Any system or component that does not respond to normal operating controls.

- Shut-off valves or manual stop valves.

- Inspectors are NOT required to enter:

- Any area that will, in the judgment of the inspector, likely be dangerous to the inspector or other persons, or damage the property or its systems or components.

- Under-floor crawl spaces or attics that are not readily accessible.

- Inspectors are NOT required to inspect:

- Underground items including, but not limited to, underground storage tanks or other underground indications of their presence, whether they are abandoned or active.

- Items that are not installed.

- Installed decorative items.

- Items in areas that are not entered as per the above.

- Common elements or common areas in multi-unit housing, such as condominium properties, townhouse associations, or cooperative housing.

- Inspectors are NOT required to: