- Inspect

- Service drop, service entry conductors, cables, and raceways

- Service equipment, main disconnects, service grounding

- Interior components of service panels and subpanels

- Conductors as readily visible

- Overcurrent protection devices

- Representative number of installed lighting fixtures, switches, and receptacles

- Ground Fault (GFCI) and Arc Fault (AFCI) devices

- Accessible smoke alarms using the “test” button

- Describe

- Amperage and voltage

- Location(s) of main disconnects and subpanels

- Presence of solid conductor aluminum 120 volt branch circuit wiring

- Presence of recognized defective service panels or subpanels

- Wiring methods

- Presence or absence of smoke detectors

- Presence or absence of CO detectors in homes with combustion appliances

- Not required

- Measure amperage, voltage, or impedance

- Operation of GFCI or AFCI if operation could cause power loss to important systems

- Remote control devices

- Low voltage wiring systems and components

- Ancillary wiring systems and components not a part of primary electrical power distribution system

Service

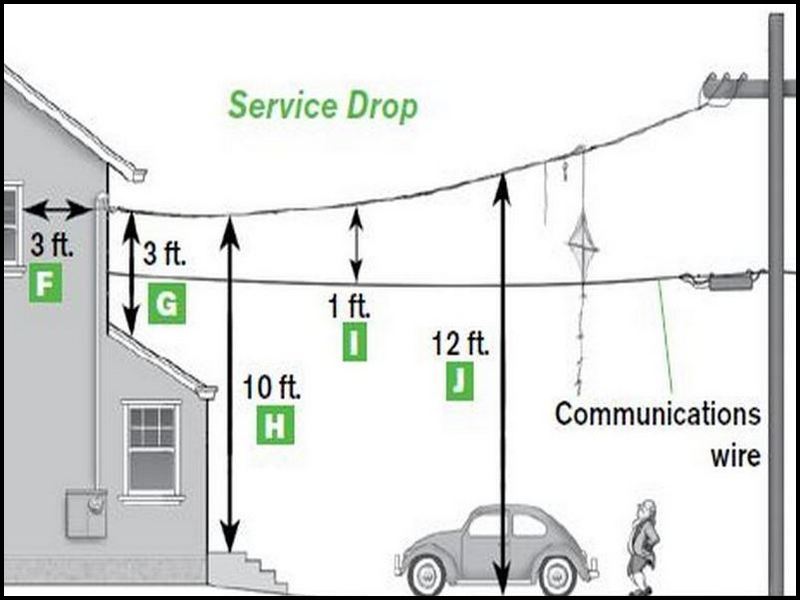

The component “Electrical – Service” includes several parts. The Service Drop is the delivery system from the utility’s residential pole or transformer to the house connection point. This may be overhead or underground. This is usually, but not always, completely the utility’s responsibility. The Service Entrance Conductors (SEC) are from the drop’s attachment point on the house to the main disconnect. This is generally the homeowner’s responsibility, and certainly so from the output of the meter to the main disconnect. If the service drop is underground, or a “lateral”, there may not be a visible SEC.

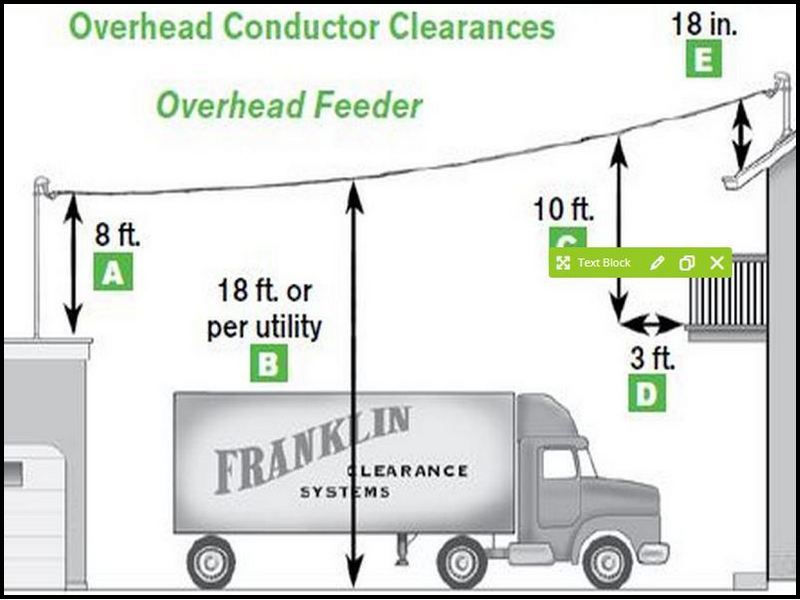

Inspect the service for clearances, condition, and capacity. All of these are safety issues, and must be evaluated regardless of who is responsible. Always exercise extreme caution, especially when using ladders, or on roofs near the service drop. Visually check the condition of the insulation. Secure attachments are essential. Be alert to installations that will allow water penetration into the meters, disconnects, conduits, or cable sheathing. Remember: the smallest capacity “link” in the wiring chain sets the maximum safe amperage for the overall system.

Proper clearances around electrical service conductors are fundamental for safety. Often, these safe distances are compromised due to aging and sagging components, damage, and renovations. It is not unusual for a new addition or deck to reduce what were once safe clearances to a hazardous condition.

The entrance cable is in contact with tree limbs. This is a safety hazard. Hire a contractor to remove the tree limbs.

The entrance cable is too low or lacks sufficient clearance from other objects. This is a safety hazard. Hire an electrician to raise the cable and/or remove obstructions.

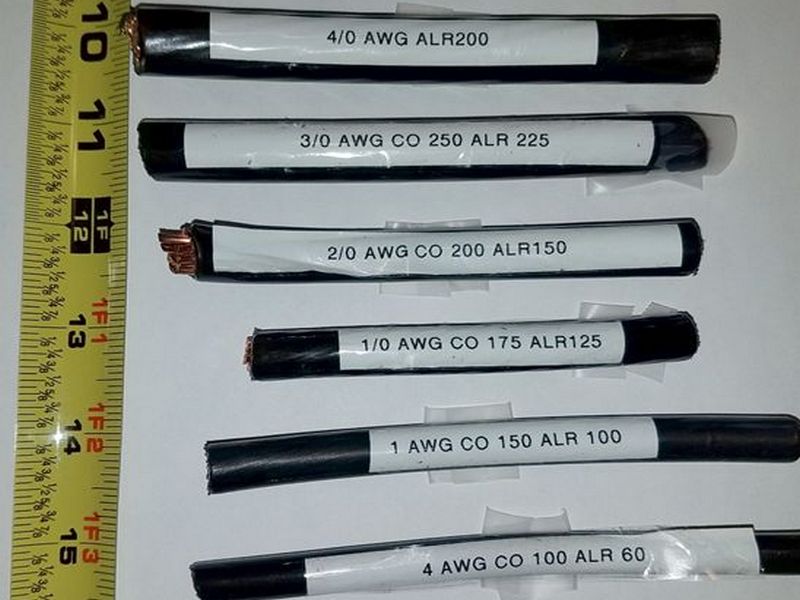

When judging the current capacity of service cable, remember that overhead drops are “air cooled.” This permits a smaller cable to safely handle more electricity than a comparable cable not in the air.

100 amp SEC

150 amp SEC

200 amp SEC

The entrance cable is improperly secured. This is a safety hazard. Hire an electrician to properly secure the cable.

The entrance cable mast is damaged. This is a safety hazard. Hire an electrician to repair the cable mast.

The entrance cable is missing a drip loop. Drip loops prevent water from entering the wiring or conduit. Hire an electrician to install a drip loop.

The entrance cable has exposed splices. This is a safety hazard. Hire an electrician to repair the cable.

There is deteriorated insulation on the service entrance cable. This is a safety hazard. Hire an electrician to replace the insulation or the cable as needed.

The entrance cable is inadequately sealed where it enters the house. This permits moisture to enter the electrical system. Seal the gaps.

The electrical service cable appears to be rated for less amperage than is servicing the main panel. This is a fire and safety hazard. Hire an electrician to make the needed repairs.

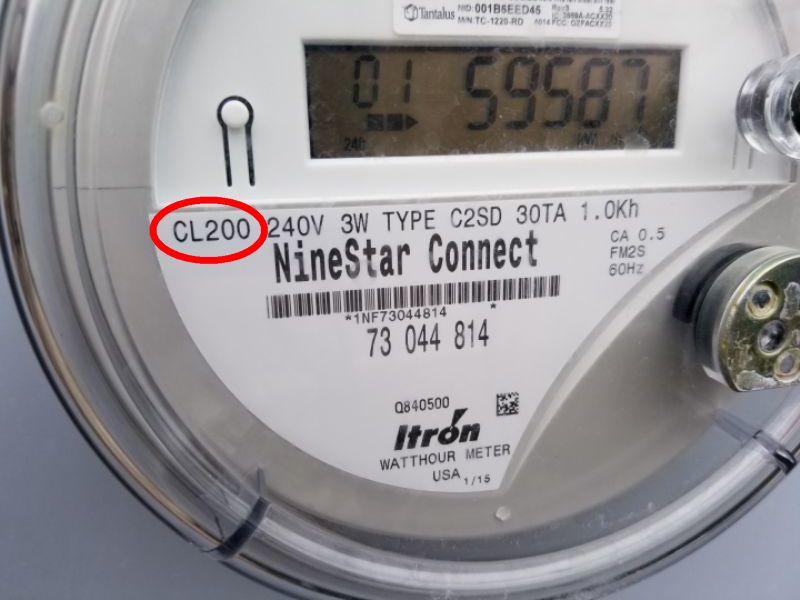

Meters and meter bases must also be inspected for proper capacity. Meters are generally clearly marked with their rating. Most current meters are 200 amps. Older homes will be the exception. They are installed by the utility company. Meter base sizes are trickier to determine. They are usually provided to the homeowner for their electrician to install. They are rated, but you would have to open one up to know for sure. Additionally, the utility company installs the meter on the base that they provide or is present on site. They are responsible. All you can do is observe and recommend if you think a mismatch exists that may be dangerous. It is not unusual to see a 200 amp meter on a smaller meter base.

100 amp meter

200 amp meter

60 amp meter base

125 amp meter base

200 amp meter base

The meter is improperly secured to the building. This is a safety hazard. Hire an electrician to secure the meter.

The conduit is disconnected at the service cable and meter junctions. This permits moisture to enter the electrical system. Hire an electrician to connect the conduit.

The meter box is damaged. This is a shock hazard. Hire an electrician to replace the meter box.

The meter box is open and the interior is exposed. This can be a significant shock hazard, and can allow water and pest intrusion. Hire an electrician to repair or replace the meter box.

The meter seal is damaged. This permits moisture to enter the electrical system. Hire an electrician to replace the seal.

The sealant where the SEC enters the meter base is damaged or deteriorated. This is a safety hazard that permits water to enter the enclosure. Hire an electrician to make the needed repairs.

The power company seal tab for the electrical meter is missing. The purpose of the seal is to prevent or indicate tampering with the meter. Have the local power company install a seal tab for the meter.

The disconnect box is not adequately secured to the structure. This can cause loose connections and is a safety concern. Hire an electrician to make the needed repairs.

The disconnect box is rusted. This is a safety and reliability concern. The extent of the corrosion cannot be determined. Hire an electrician for an evaluation and to make repairs as needed.

The disconnect box does not properly close to form a weatherproof enclosure. This is a safety concern and a shock hazard. Hire an electrician to make the needed repairs.

There are obstructions to the main electrical disconnect. The disconnect needs to be readily accessible in an emergency for safety reasons. Remove the obstructions.

Service Limitation and Information Statements

Unable to determine service size: The inspector is unable to determine the service size of the electrical system. This occurs in cases in which service entrance conductors are not visible or are connected to switch gear on an inaccessible side of a panel with larger service.

Solar panels, not inspected: There are solar panels present on the property which are beyond the scope of a home inspection. The solar panels are not inspected.

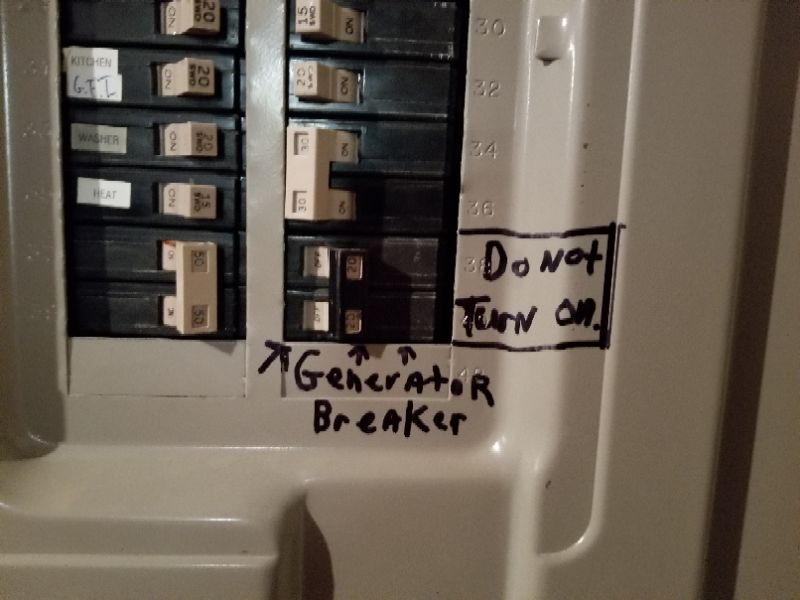

Generator/generator connection present, not inspected: A permanently-installed standby generator or a portable generator connection is present. The operation of standby generators and their associated transfer panels is beyond the scope of this inspection. Only the visible and readily-accessible portions of portable generator connections are inspected. Have an electrician evaluate any permanently-installed generators and systems prior to closing.

Applicable state regulations require that the seller provide a certificate: Applicable state regulations require that the seller provide a certificate that the smoke and CO detectors have been inspected within 120 days prior to the date of sale. Inspections shall be done by the local fire department or the Office of the State Fire Marshal. Therefore, our inspection of these devices is limited.

Electrical system may need to be upgraded if higher-demand electrical appliances used, consider hiring electrician to evaluate upgrade requirements: The electrical system may need to be upgraded if more or higher-demand electrical appliances will be used. Although the electrical system may have been appropriate at the time of its installation, the system may not meet current needs or certain lender requirements. Consider hiring an electrician to evaluate upgrade requirements.

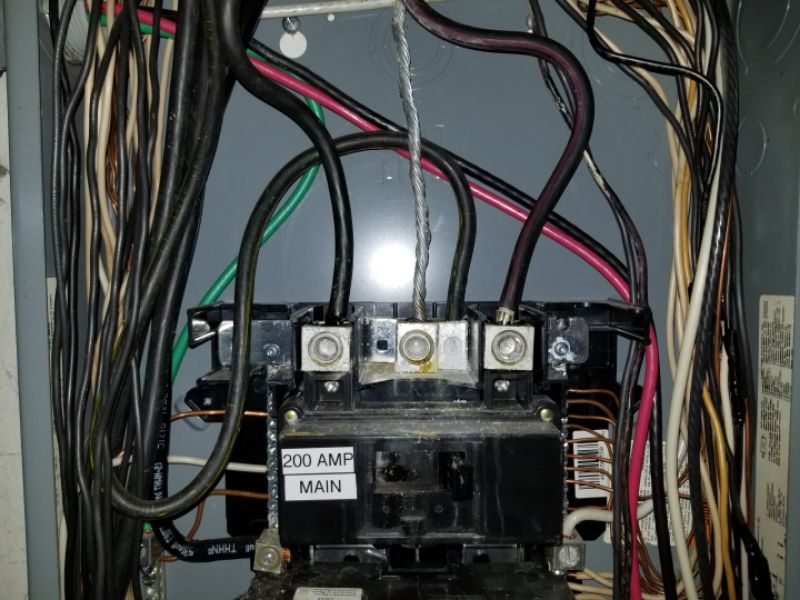

Panel

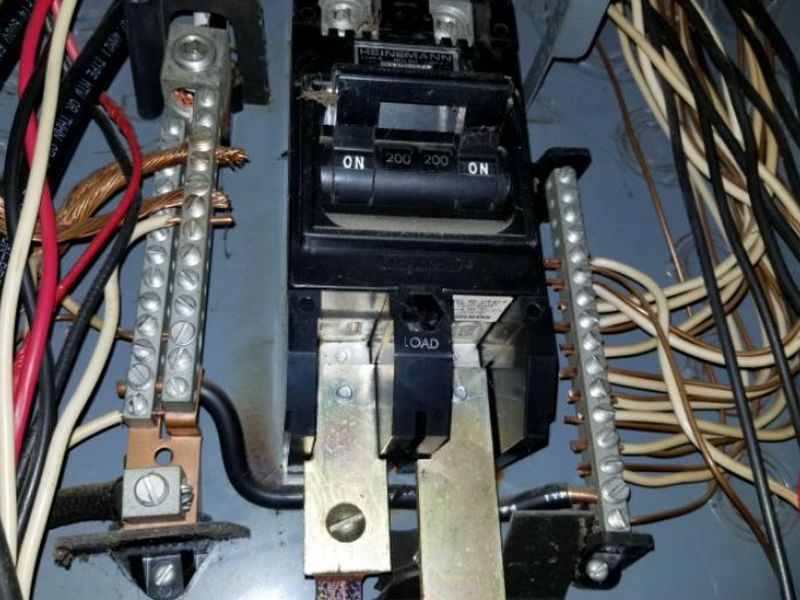

It’s vital to be clear about electrical terms. Our component “Electrical – Panel” refers to the first Overcurrent Protection Device (OCPD/breaker/fuse) after the service entry. This equipment disconnects the utility’s power from the building at the customer’s end of the service entrance conductor (SEC). In most cases, this will also be the “service panel”, or “main breaker panel.” However, if the service entry is a distance from the service panel, a single OCPD disconnect will be installed close to the entry. This main disconnect then becomes the component that we refer to as the “main” panel. What the homeowner will view as the “breaker box” is now actually a “sub panel”. This is a critical point to understand, as sub-panels must be wired differently than service panels.

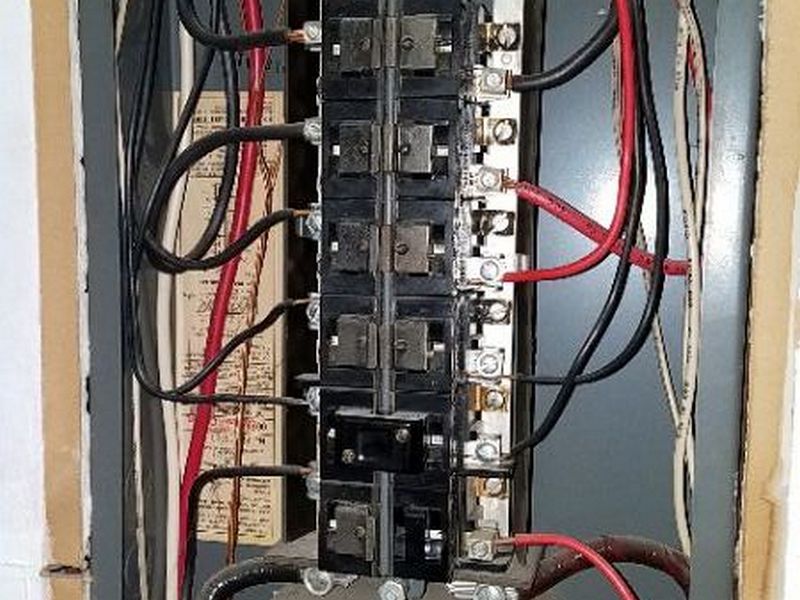

Confirm a securely mounted, well-labeled service panel, free of openings, damage, or deterioration. The interior “dead front” cover must be removed, or reported that it could not. Look for overheated wires, oversized, loose, or damaged breakers/fuses, double taps, and mismatched components. Be alert to “problem” panels that are unsafe. All circuits in a service panel must be able to be de-energized with no more than 6 breakers.

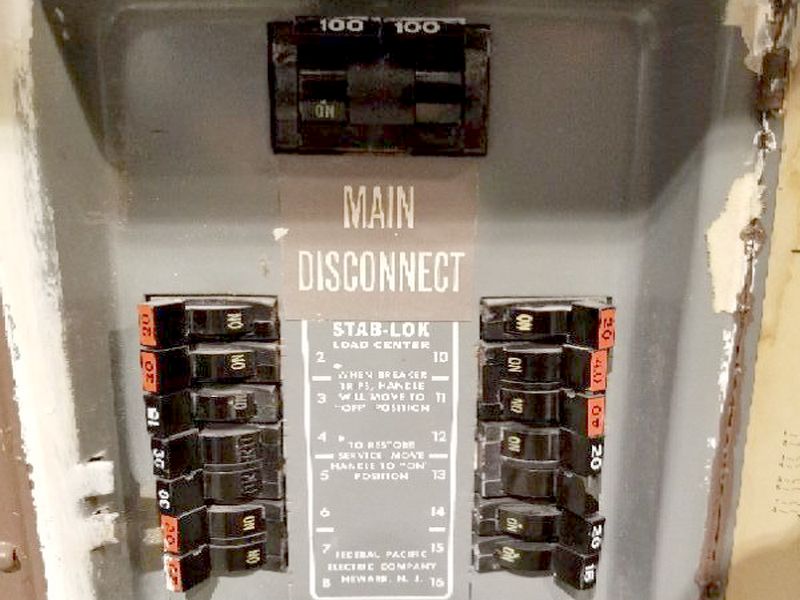

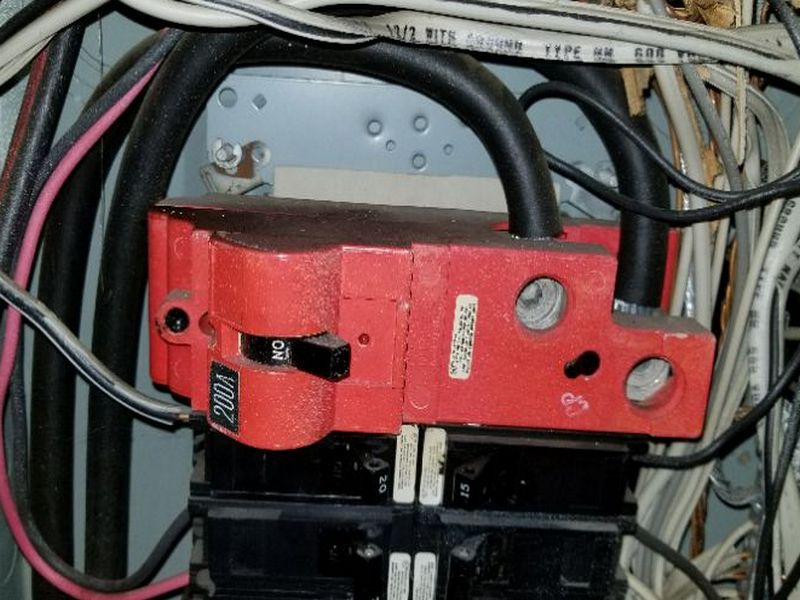

The following panels and breakers should always be reported as a defect regardless if there are issues visible or not. They have a documented history of safety concerns. Use the provided language to recommend a panel replacement or breaker evaluation.

There is a Federal Pacific Electric breaker panel present. These panels have an established history of safety issues, including overheating and arcing. Hire an electrician to replace the panel.

There is a Zinsco/Kearney breaker panel present. These panels have an established history of safety issues, including overheating and failing to trip. Hire an electrician to replace the panel.

There is a Pushmatic breaker panel present. There have been reports of safety issues involving failures to trip due to a less reliable mechanism. Additionally, the breakers can become difficult to operate and not show a tripped status. Hire an electrician for an evaluation and to make repairs as needed.

There is a Murray brand breaker panel with a “red” main breaker installed. There have been reports of problems with these breakers, including overheating and arcing at the breaker connections. Hire an electrician for an evaluation and to make repairs as needed.

There are missing blunt-tipped screws at the electrical panel’s cover. This is a safety requirement to ensure an adequate seal around the panel box. Hire an electrician to install blunt-tip screws.

There are pointed screws securing the electrical panel’s cover. These can penetrate a conductor and cause a shock hazard. Hire an electrician to replace the screws.

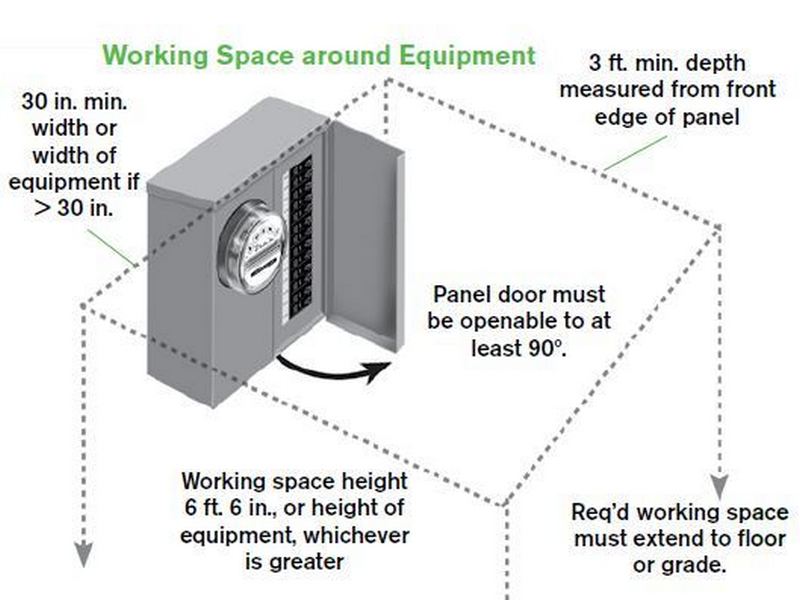

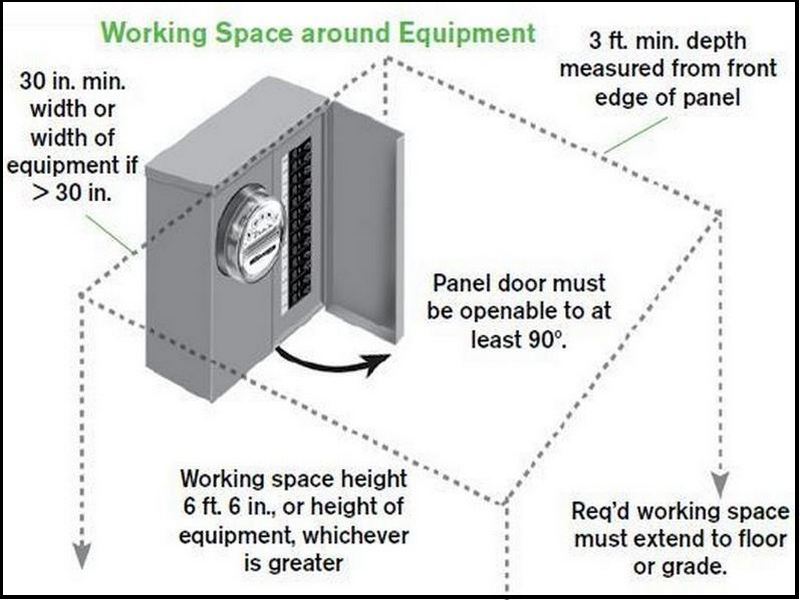

There is inadequate clearance at the electrical panel. A minimum of 36″ is required in front of the panel, and the door must open to 90. Remove the obstructions.

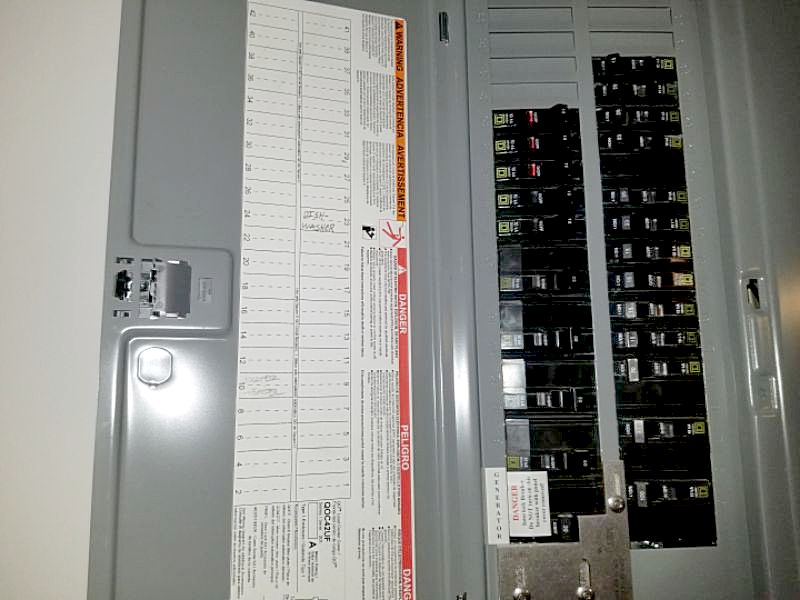

The electrical panel is partially labeled. All panels should be labeled correctly to indicate which circuits the breakers or fuses serve. Relabel the panel.

The electrical panel is improperly secured to the wall. This is a safety hazard. Hire an electrician to make the required repairs.

There are missing knockout covers at the electrical panel. This defeats the panel’s fire rating, and permits accidental contact with energized components. Hire an electrician to make the required repairs.

The electrical panel is missing a “dead front” cover. This is a safety hazard as the energized interior components are exposed. Hire an electrician to install a cover.

The electrical panel is in an improper location. Safety requirements prohibit panels in bathrooms, clothes closets, or over stairways. Hire an electrician for an evaluation and to make repairs as needed.

The electrical panel is recessed into a finished wall, creating a gap between the panel cover and its enclosure. This is a shock hazard and defeats the panel’s safety rating. Hire an electrician to make the required repairs.

There is moisture in the electrical panel. Rust and corrosion affect a panel’s safe operation. The cause of the moisture must be identified. Hire an electrician for an evaluation and to make repairs as needed.

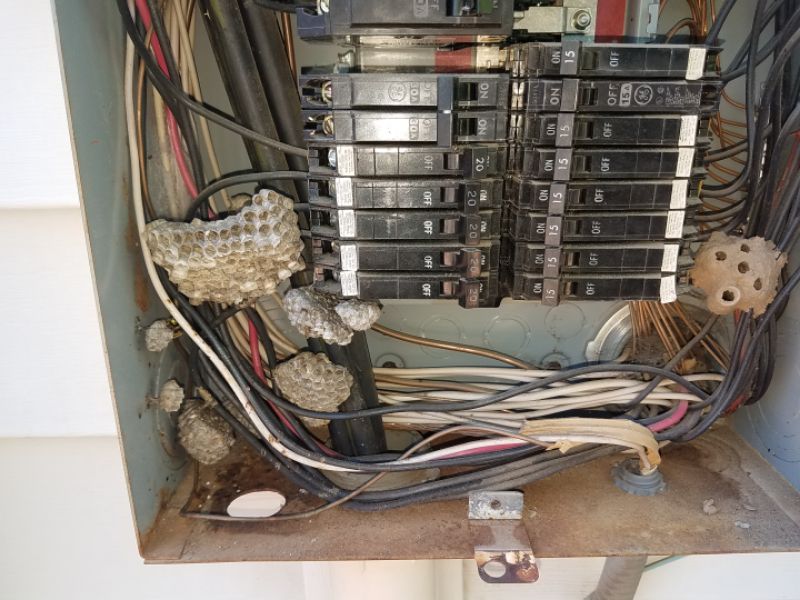

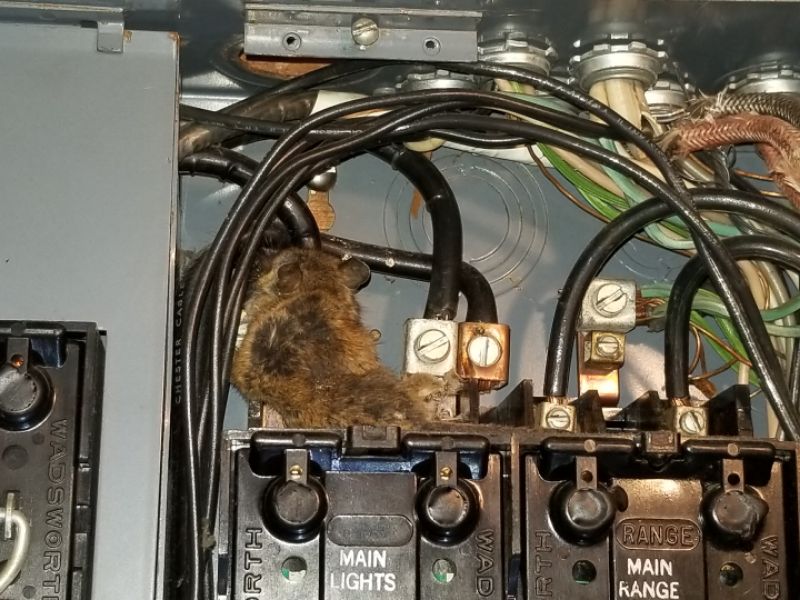

There are animals nesting in the electrical panel. This is a safety hazard. The entry point should be identified and sealed. Hire an electrician for an evaluation and to make repairs as needed.

A breaker or fuse is an Overcurrent Protection Device, or OCPD. Its job is to clear ground faults to prevent shock hazards, and to protect the circuit wiring. Excess electrical current can cause a conductor to overheat and fail, creating a fire hazard. This is why the wiring’s current rating is the determining factor in a circuit’s capacity, and hence what the OCPD should be.

In copper household wiring, a 12 AWG NM or “Romex” conductor is rated for 20 amps, while a comparable 14 AWG is only allowed 15 amps. Note that the example says copper. Aluminum is not as good an electrical conductor as copper. In a 120 volt circuit using single-strand aluminum wiring, the conductors must be one size larger. Hence, a 15 amp OCPD on a circuit must feed 12 AWG single-strand aluminum wire, not 14 AWG. You should become familiar with common wire gauges so you can visually identify them. Many inspectors carry small, labeled samples of the most common wires sizes. Modern NM cable is color-coded.

There are oversized breakers at the electrical panel. This is a safety hazard. When a breaker has a higher rating than the wire it serves, the wire will overheat before the breaker trips. Hire an electrician to replace the breakers.

There are oversized fuses at the electrical panel . This is a safety hazard. When a fuse has a higher rating than the wire it serves, the wire will overheat before the fuse blows. Replace the fuse with a correct-size one.

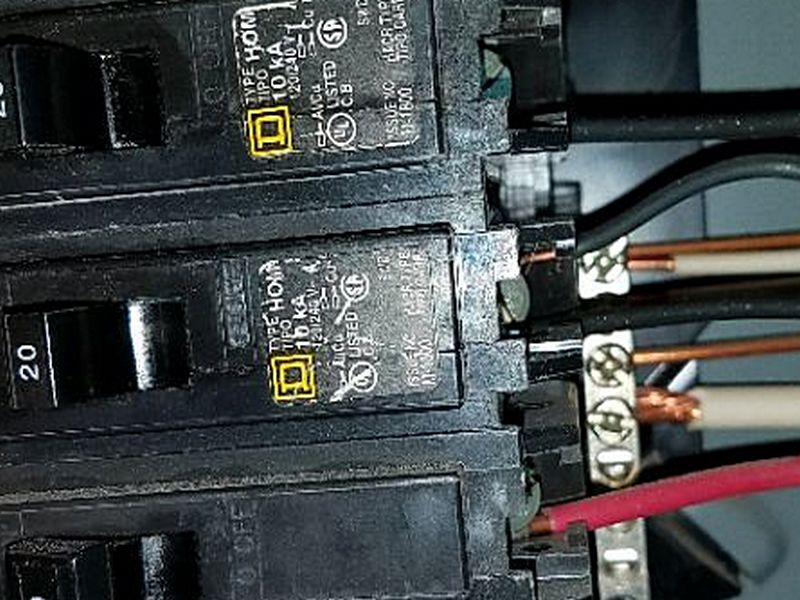

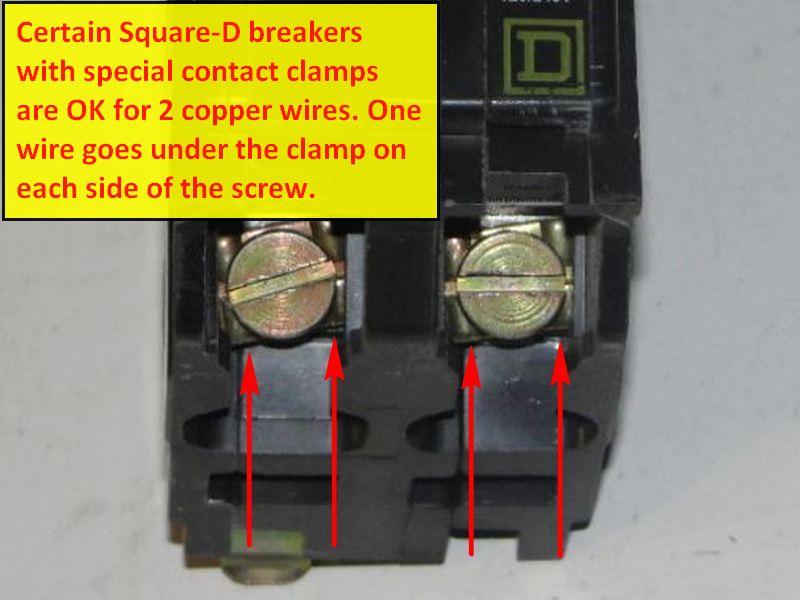

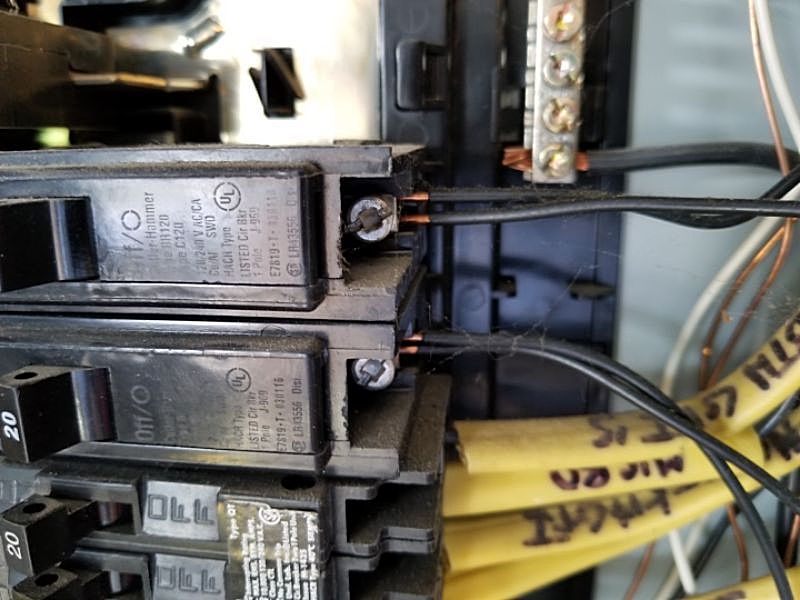

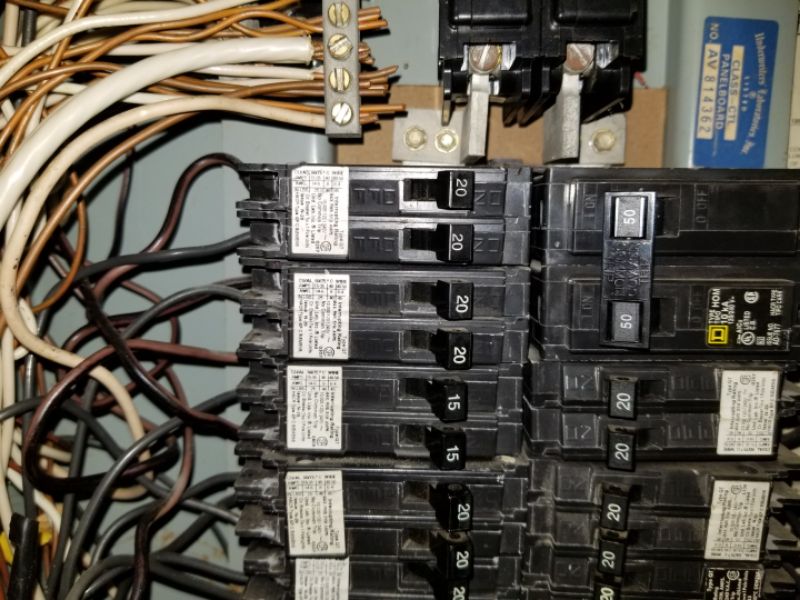

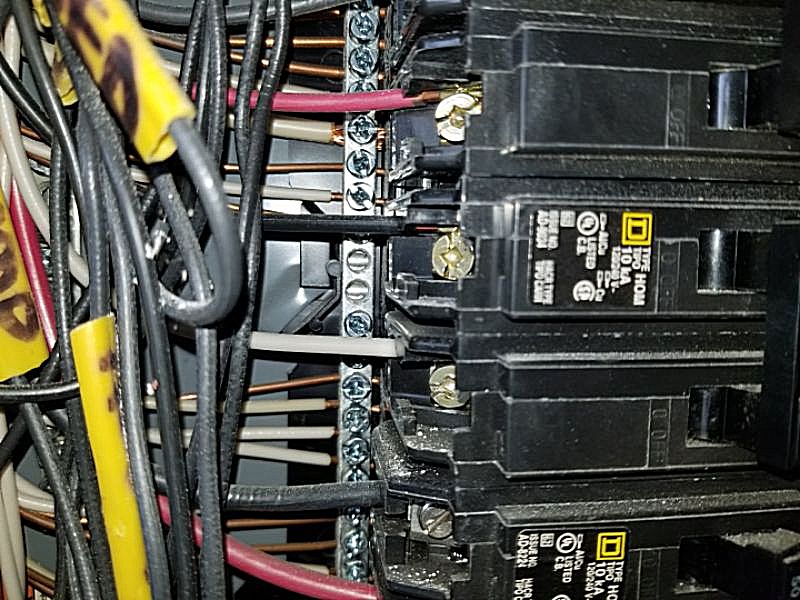

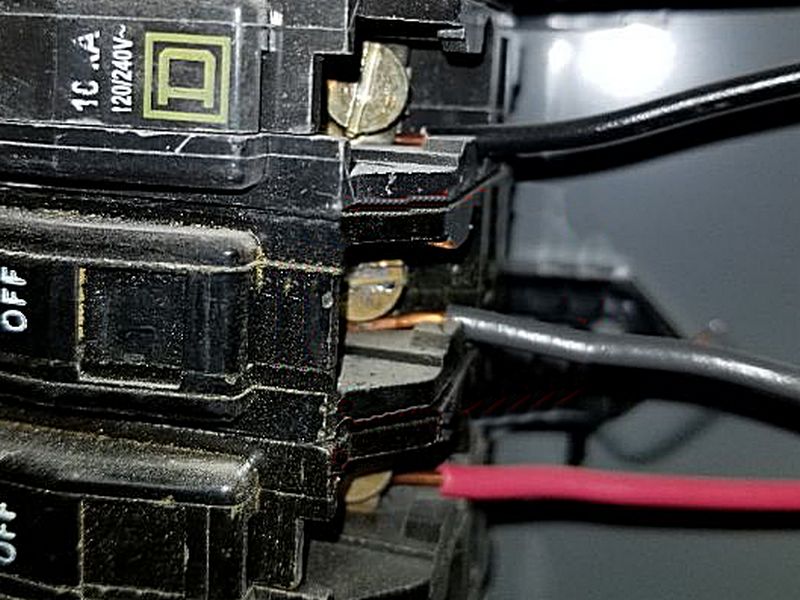

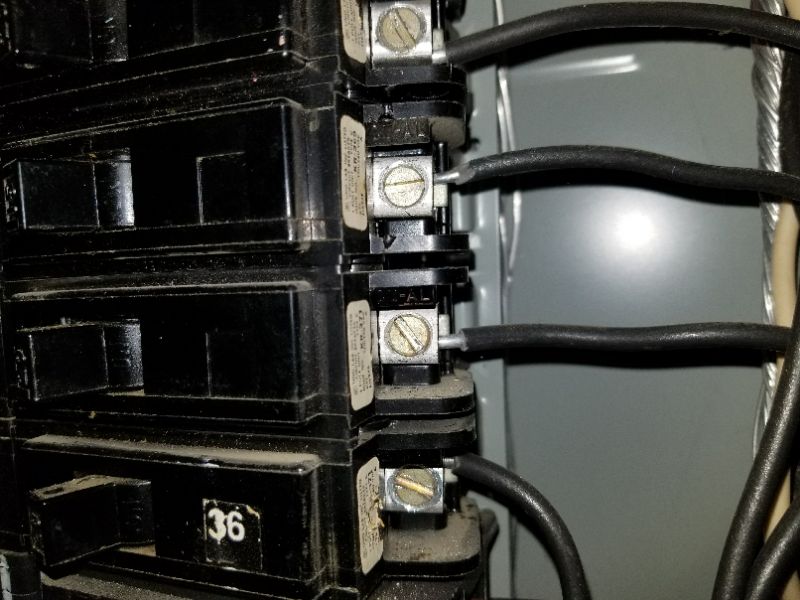

There are double-tapped breakers or fuses at the electrical panel. Most contacts are not designed to safely secure more than one wire. Hire an electrician to make the required repairs.

There are incompatible breakers installed at the electrical panel. Breakers not approved by the panel’s manufacturer can affect safe operation. Hire an electrician to make the required repairs.

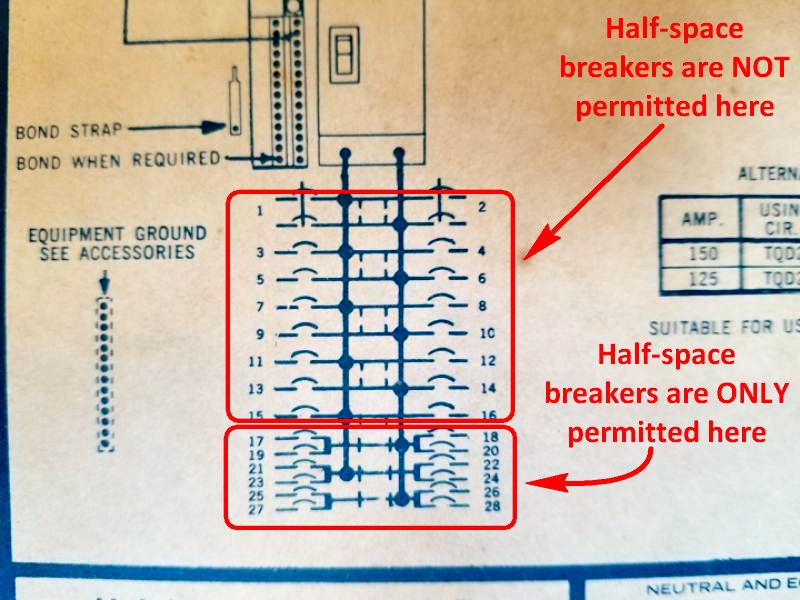

There are improperly-installed half-space breakers at the electrical panel. The manufacturer provides a chart indicating what type of devices can be used and where they can be placed. Hire an electrician to make the required repairs.

There are loose breakers at the electrical panel. This is a safety hazard due to the potential for arcing and overheating. Hire an electrician to repair or replace the breakers.

There are breakers in the electrical panel that are in the off position. The reason for this is not known. We do not turn on breakers. Hire an electrician for an evaluation and to make repairs as needed.

There are missing tie bars for two-pole breakers at the electrical panel. These are required to ensure that both legs of the breakers trip together. Hire an electrician to install tie bars.

The electrical panel requires more than 6 breakers to turn off all the power to the home. This is contrary to accepted practice and is a safety concern. Hire an electrician to evaluate the panel and to make required repairs.

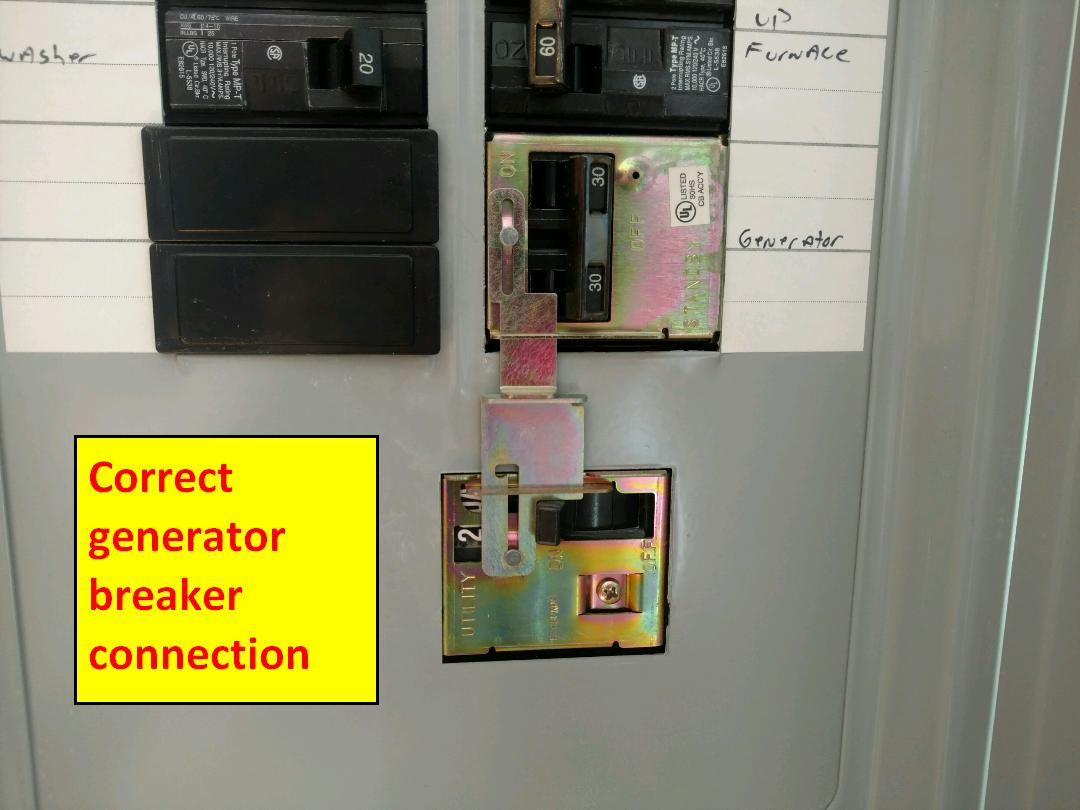

There is an improper generator connection at the electrical panel. The installation must ensure that the utility’s main breaker and the generator’s input breaker cannot be “on” at the same time. Hire an electrician to make the required repairs.

There are improperly secured wires at the electrical panel. Safety standards require a retainer where wires enter the panel. Hire an electrician to make the required repairs.

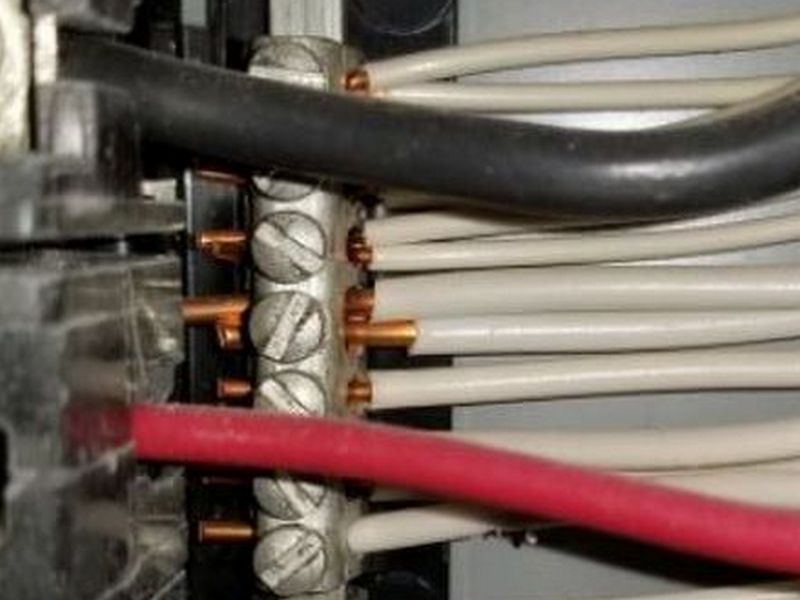

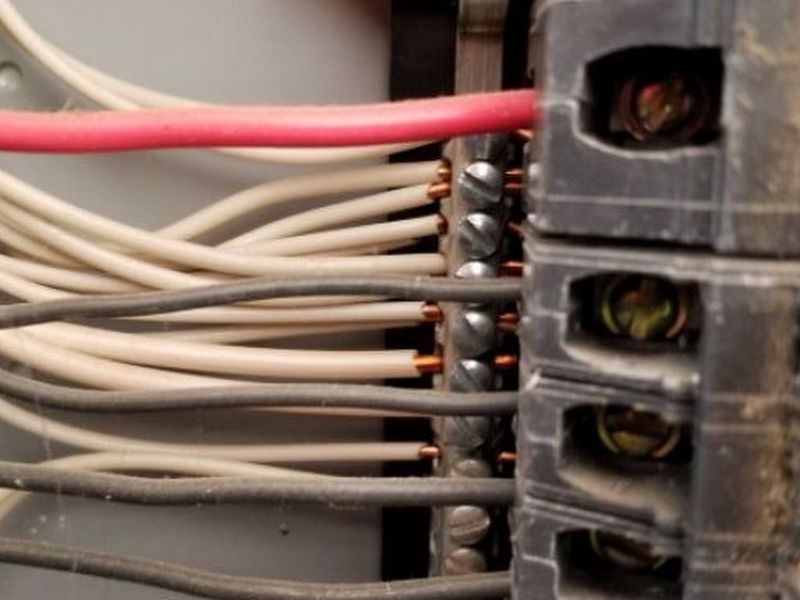

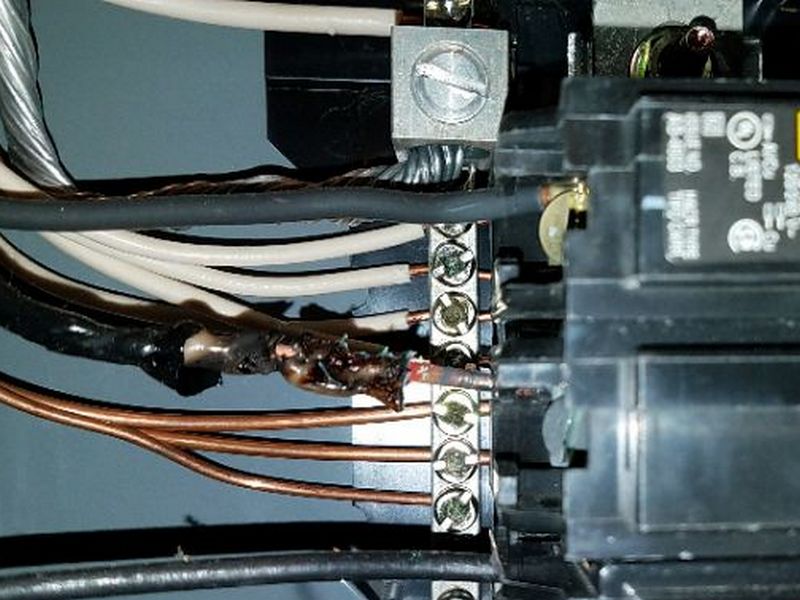

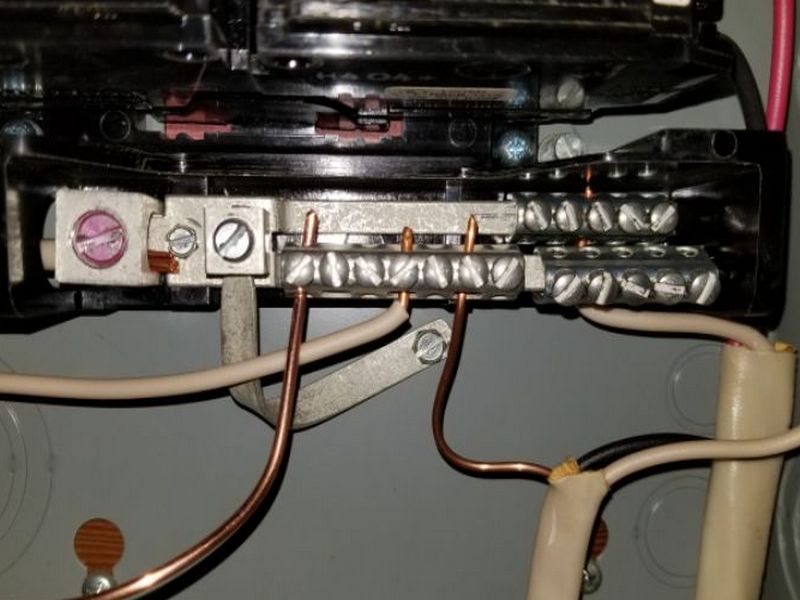

There is more than one neutral wire connected to a single contact on the neutral bar. This is no longer permitted as most contacts are not designed to safely secure multiple wires. Hire an electrician to make the required repairs.

There are unmarked neutral wires connected to double-pole breakers or fuses. This is a safety hazard. Neutral wires must be marked to indicate that they are current-carrying conductors. Hire an electrician to make the required repairs.

The electrical panel’s aluminum connections are missing antioxidant paste. This is a safety requirement. Hire an electrician to apply antioxidant paste.

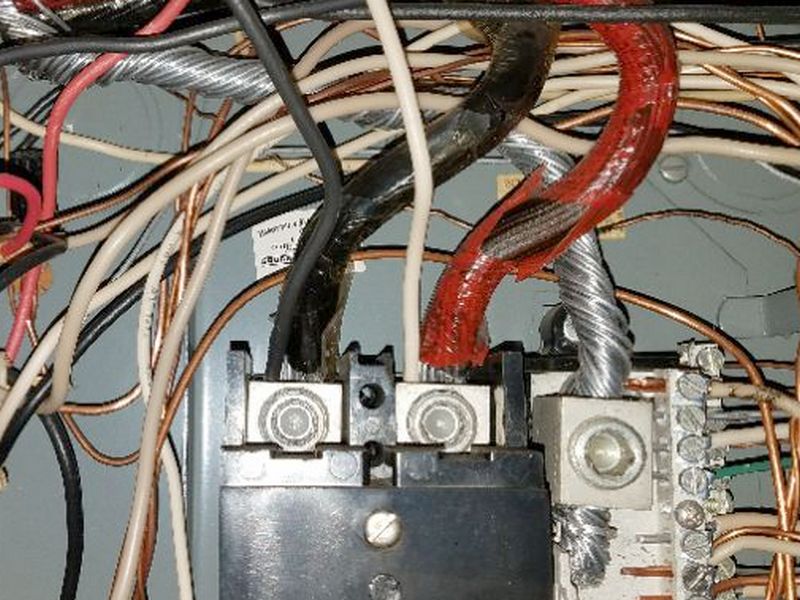

There is excessive sheathing missing from the wiring where it connects to the breakers at the electrical panel. This is a safety hazard. Hire an electrician to make the required repairs.

There are loose wire connections at the electrical panel. This is a safety hazard due to the potential for arcing and overheating. Hire an electrician to make the required repairs.

There are improperly terminated wires inside the electrical panel. This is a safety hazard. Hire an electrician to make the required repairs.

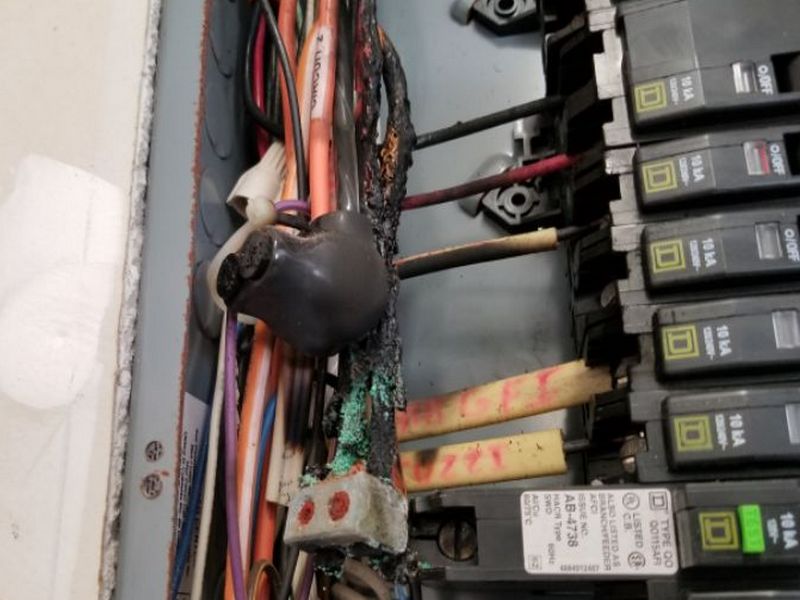

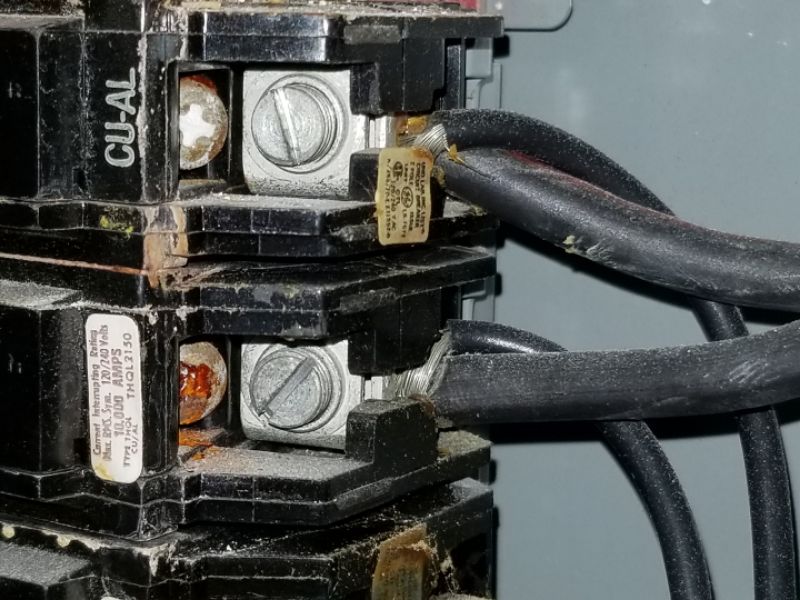

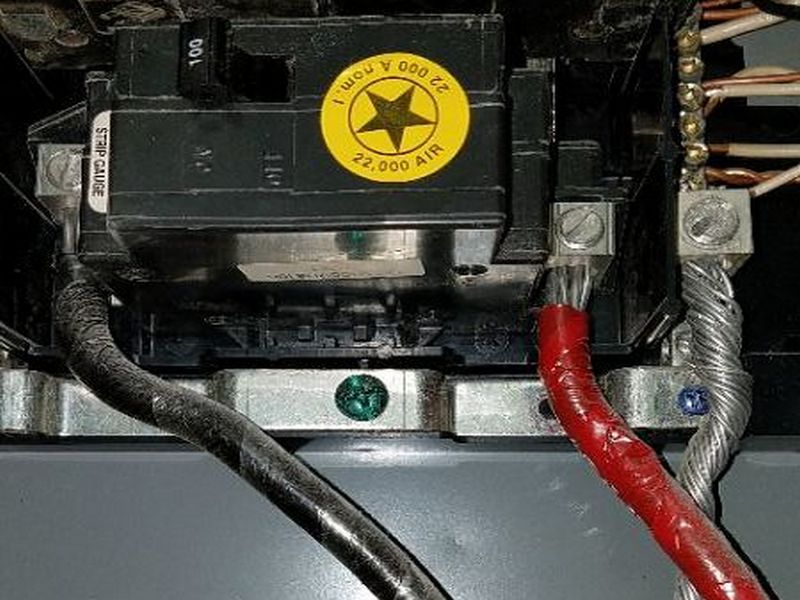

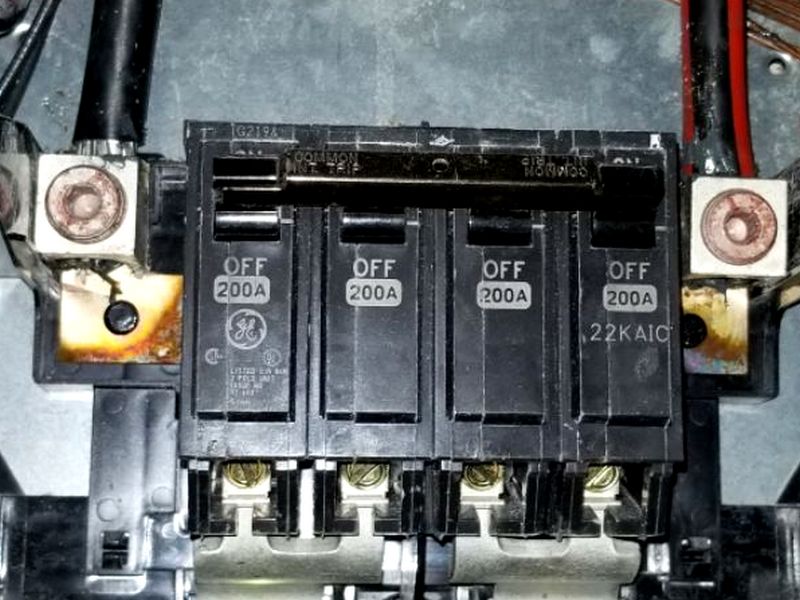

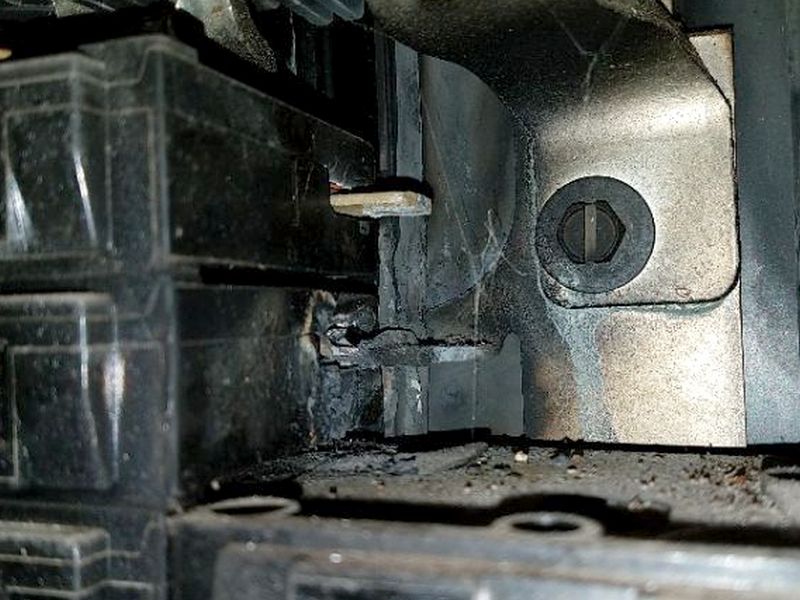

There are overheated wires at the electrical panel. This is a safety hazard. The reason for this must be identified. Hire an electrician for an evaluation and to make repairs as needed.

There are scorch marks inside the electrical panel. This indicates arcing and/or overheating. The cause of the problem must be identified. Hire an electrician for an evaluation and to make repairs as needed.

There are improper taps on the main lugs at the electrical panel. This is a safety issue. Hire an electrician to make the required repairs.

There is a doorbell transformer installed inside the electrical panel. This is not permitted for safety reasons. Hire an electrician to make the required repairs.

Panel Limitation and Information Statements

Locked, not operated/tested: The panel is locked and, therefore, is not operated or tested.

Blocked, not operated/tested: Access to the panel is blocked and, therefore, it is not operated or tested.

Sealed cover, no access to interior: The cover to the electrical panel is sealed. Access to the interior is not possible. Permission has not been given to take actions necessary to complete the inspection. Have an electrician evaluate the panel when possible.

“Split bus” panel, older load centers do not have single “main” breaker, panel divided into 2 or 3 sections, “disconnect” section feeds power to lower section(s): The electrical panel is a “split bus” panel. These older load centers do not have a single “main” breaker. The panel is divided into 2, and sometimes, 3 sections. The “disconnect” section, usually at the top, feeds power to the lower section(s). They are required to be set up so that all power to the building’s circuits can be shut off using no more than six disconnects in the main section. This is called the “6-throw rule.”

Sub-Panel

Sometimes, a breaker or fuse panel is required at some distance from the home’s main electrical service disconnect. That main disconnect may be a single OCPD at the service entry, or the “main” breaker panel. The downstream panel is called a “remote distribution panel”, what we commonly refer to as a “sub-panel.” It’s important to understand that any distribution panel downstream of the main service disconnect is a sub-panel. If the house has a service disconnect separate from the only breaker panel in the building, that sole breaker panel is still a sub-panel. If electricity is drawn off the only panel in the home to another panel, that other panel is a sub-panel, even if the “main” panel is also a sub-panel.

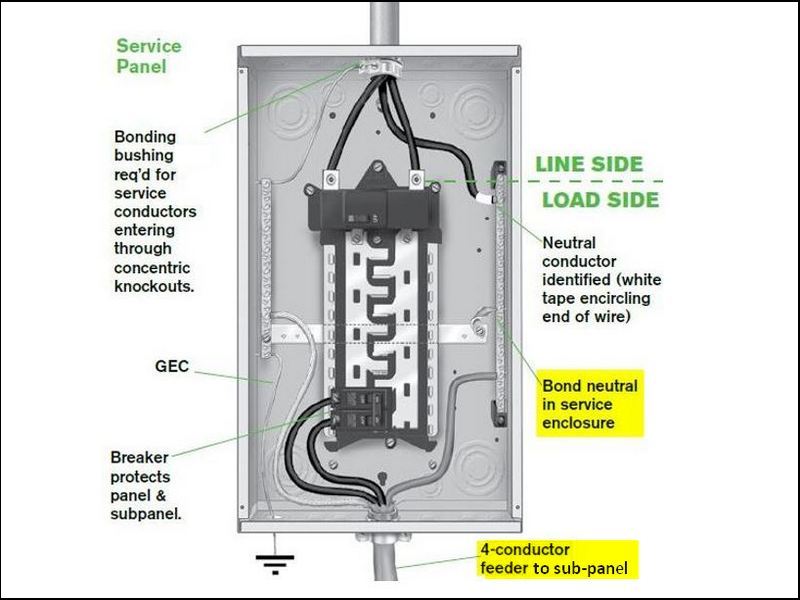

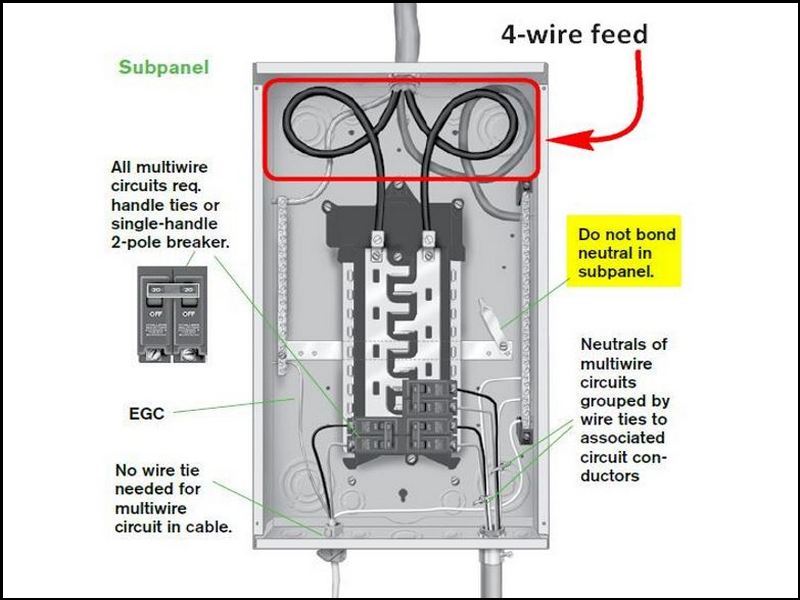

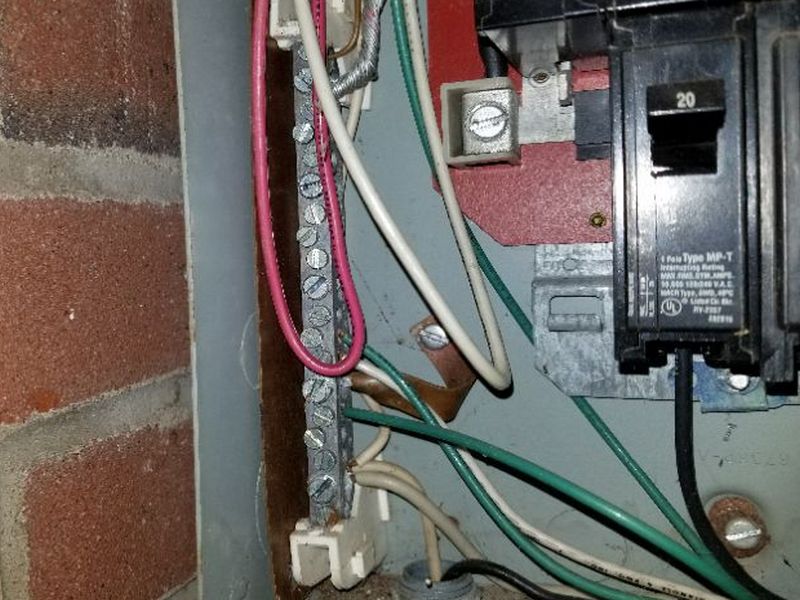

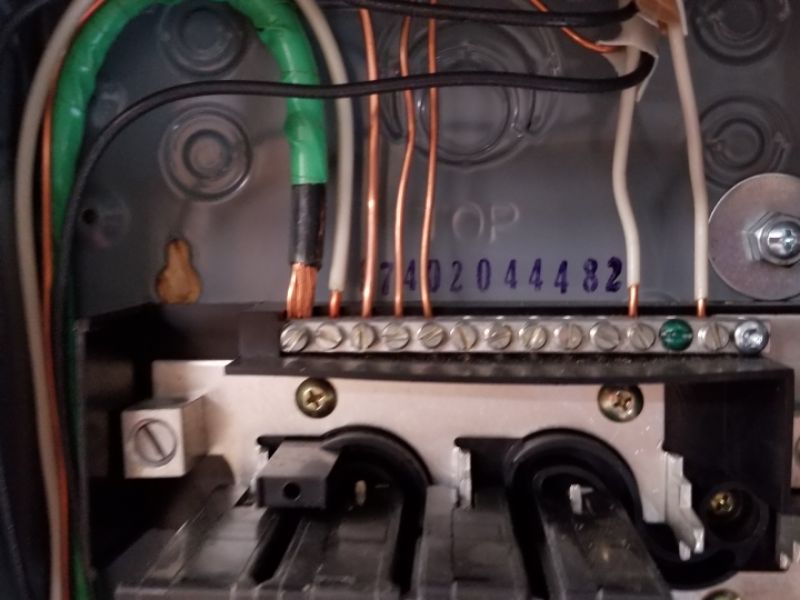

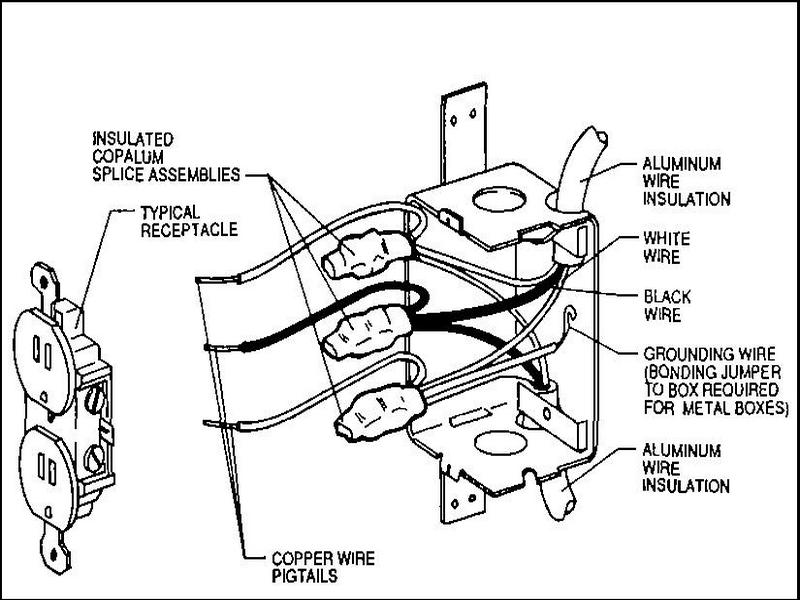

We are not just fussing over terms here! “Main” service panels and “sub-panels” are wired differently to prevent harmful electrical currents from developing where they shouldn’t be. This is accomplished by NOT connecting the “grounded” white neutral wires to the bare/green “grounding” wires in a sub-panel. Sub-panels should be fed by a 4-wire circuit: 2 hot wires (black and red), 1 white neutral, and a bare or green grounding conductor.

Sub-panels can have all of the same defects as “main” panels, and then some. For that reason, we will only cover defects specific to sub-panels here. Refer to the “Panel” section of Inspecto Libro for defects common to all distribution panels.

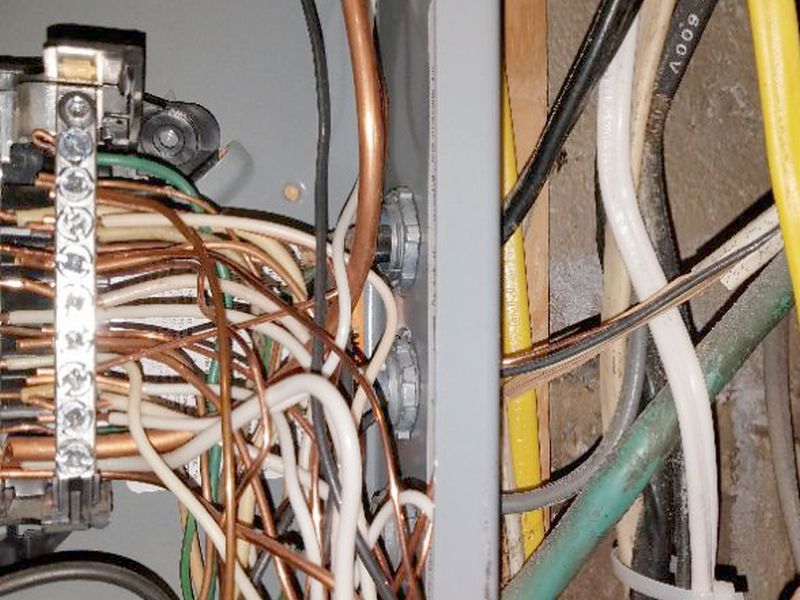

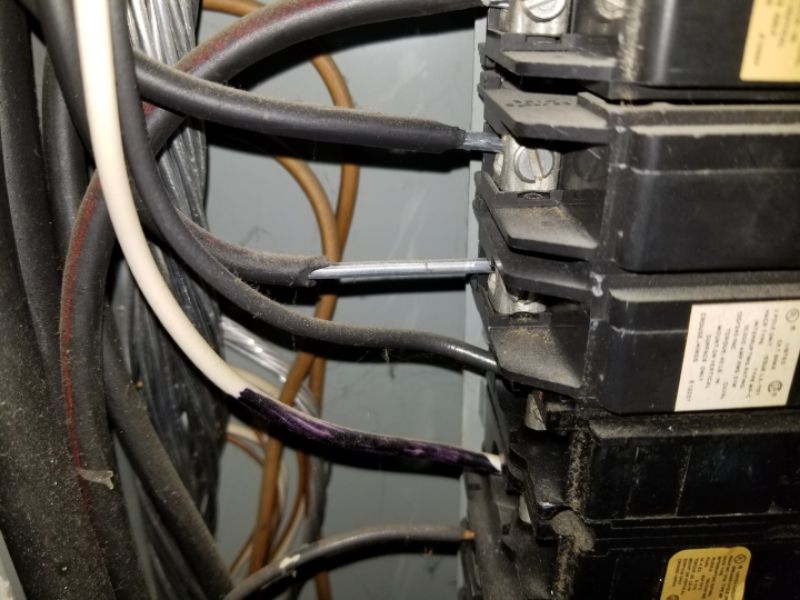

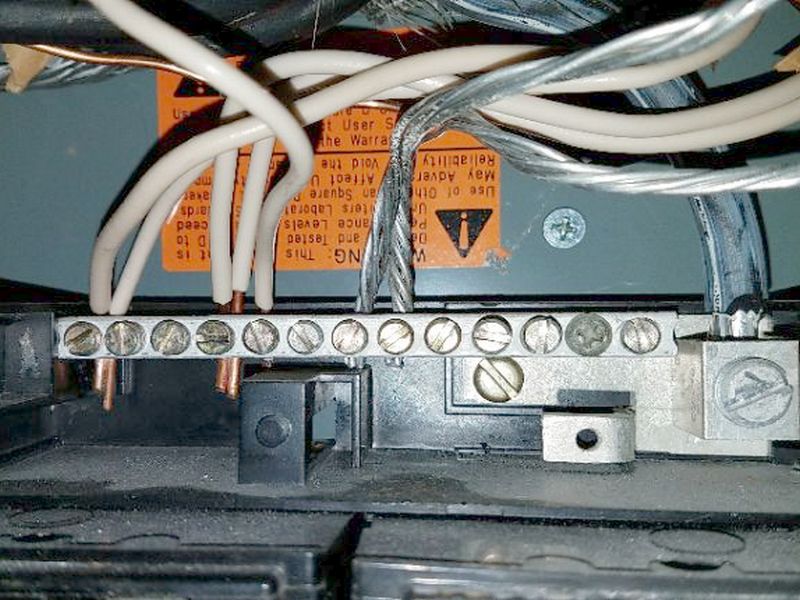

Service Panel wiring (main disconnect):

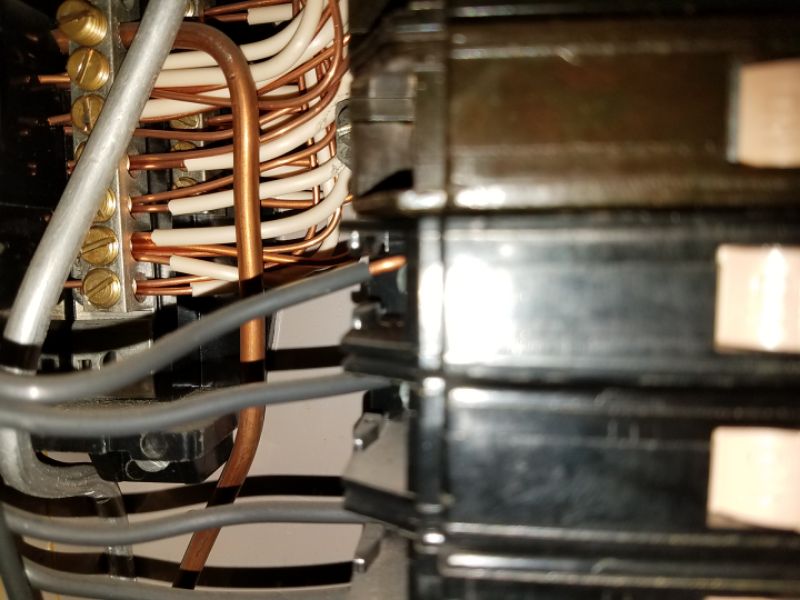

Sub-Panel wiring (note the unbonded neutral and 4-wire feed):

The sub-panel’s neutral wires are not isolated from ground. This is a safety hazard. Hire an electrician to make the required repairs.

Sub-Panel Limitation and Information Statements

Locked, not operated/tested: The sub-panel is locked and, therefore, is not operated or tested.

Blocked, not operated/tested: Access to the sub-panel is blocked and, therefore, it is not operated or tested.

Sealed cover, no access to interior: The cover to the electrical sub-panel is sealed. Access to the interior is not possible. Permission has not been given to take actions necessary to complete the inspection. Have an electrician evaluate the sub-panel when possible.

Branch Circuits

In the component “Branch Circuits” we are considering the actual wiring; the conductors that carry electricity throughout a home. Wiring systems and materials have evolved considerably over the years. Unless you only inspect new construction, you are very likely to encounter many installations that are now considered obsolete. In the “Red Flag” Wiring Systems section you will review several older systems that, at a minimum, must be inspected carefully or be recommended for a full evaluation.

Remember that the majority of the house wiring is not visible at all. It’s important to pay close attention where it is available, e.g. panels, attics, basements, crawlspaces. You may need to move aside some insulation, or get a bit closer, to see whether a defect is present. Maybe there’s knob & tube wiring under that loose fill, or that branch wire is actually marked “AL” or “Kaiser.”

Single Strand Aluminum Wiring

Single strand aluminum wiring in the lower 120 volt branch circuits should always be reported with a recommendation for further evaluation and repairs. This system was installed from the mid-1960s through the mid-1970s. Deterioration in the wire connections can cause increased resistance to the flow of electric current, resulting in damage that is cumulative in effect. That increased resistance causes overheating, sometimes at hazardous levels, when current is flowing in the circuit. The concerns do not apply to large gauge 240 volt circuits such as SECs, water heaters, dryers, and stoves.

The Consumer Product Safety Commission (CPSC) strongly recommends remediation of single strand aluminum wiring wherever present. They only approve of 3 repair methods, which are outlined next. The CPSC Repair Bulletin can be found at https://www.cpsc.gov/s3fs-public/516.pdf .

Complete removal of all single strand aluminum wiring and replacement with copper wiring is an obvious solution, and is one of the 3 choices approved by the CPSC. However, this is very expensive and disruptive. It is not considered necessary in most cases.

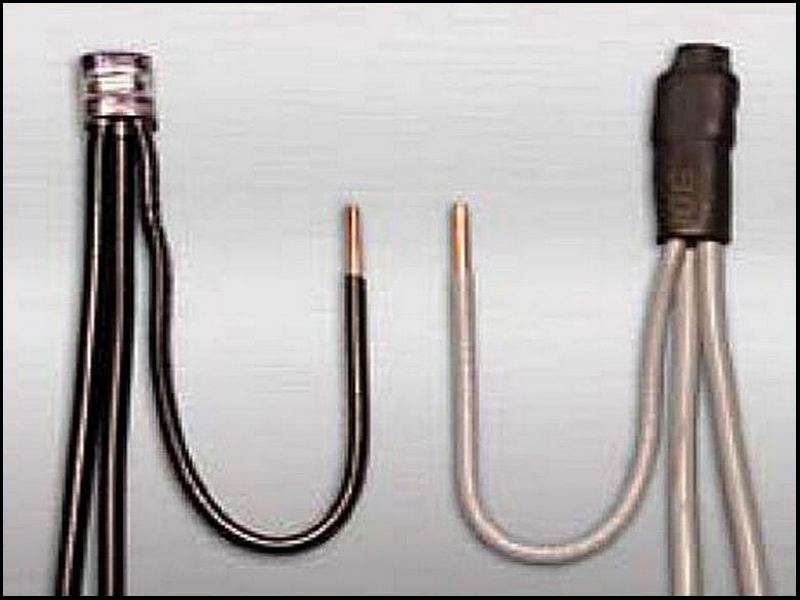

The COPALUM system involves using a special tool and connectors to permanently “cold weld” a short copper pigtail to the aluminum wire termination. The pigtail is then used to make the final connection. This must be done at ALL aluminum wire terminations and connections, including junction boxes, switches, receptacles, and fixtures. Only electricians who are trained by the manufacturer to use the tool properly are authorized to install COPALUM connectors.

The AlumiConnn® connector system is also approved for pigtail remediations. As with the COPALUM system, all connections and terminations must be repaired. However, no certification is required for the AlumiConn® connector. The repair should be conducted by a qualified electrician because careful, professional workmanship and thoroughness are required to make the connector repair safe and permanent.

![]()

![]()

Note that other methods are NOT approved as reliable or permanently safe. This includes CU/AL and CO/ALR devices, e.g. switches and receptacles. Twist-on pigtails, including the Ideal #65 Purple Twister, are not approved.

Failed Ideal #65 Purple Twister

There is single strand aluminum wiring present on 120V circuits. This wiring has an established history of safety problems, including loose connections, arcing, overheating, and fires. Hire an electrician for an evaluation and to make repairs as needed. For further information on aluminum wiring contact the U.S. Consumer Product Safety Commission at: https://www.cpsc.gov/s3fs-public/516.pdf .

Knob and Tube Wiring

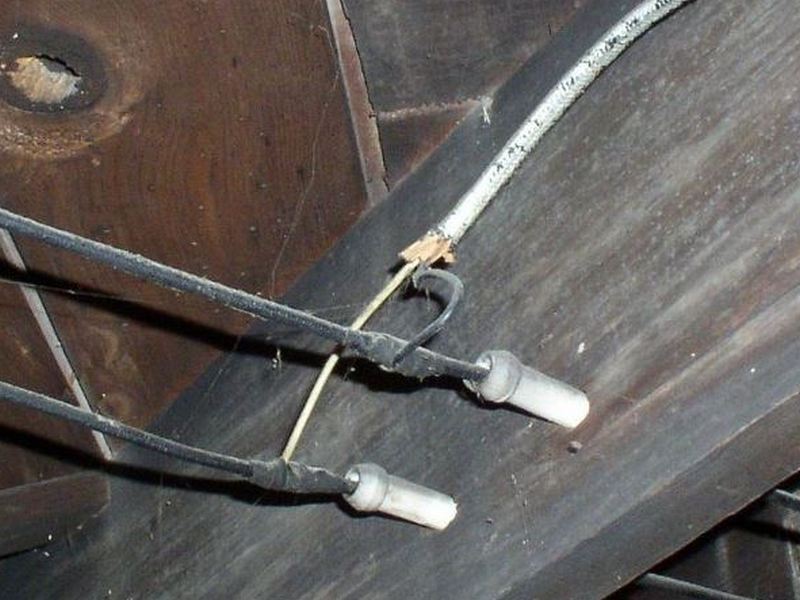

Knob and Tube is an early form of standardized wiring, and was installed through to the end of the 1930s. Instead of the single cable with multiple conductors that we use today, it ran separate hot and neutral wires. These copper wires used rubber insulation and a cloth sheathing. They were installed on the framing with stand-off ceramic “knobs”, and passed through the framing inside of ceramic “tubes.” As there are only 2 wires the system cannot be grounded. We always report knob and tube with a recommendation for a further evaluation.

Knob and tube installations are generally grandfathered, and if in good condition it is not, in and of itself, unsafe. The problem is that it’s rarely in really good condition. The rubber insulation can become brittle, and break off when moved by renovations, household activity, or animals. Rodents can damage the wiring. Additionally, new circuits are frequently spliced on in an unsafe manner. In the late 1980s, the NEC banned covering knob and tube with insulation because the wires are supposed to be “air cooled.” While a few western states overrode that prohibition, it still stands everywhere else. Inspect its physical condition carefully, and don’t take a statement about “all old wiring updated” as 100% accurate.

There is knob and tube wiring present. This older system cannot be grounded, and often has brittle or damaged insulation. The wiring should be evaluated for condition and safety concerns. Hire an electrician for an evaluation and to make repairs as needed.

There is knob and tube wiring present which is covered with insulation. This is not permitted due to the potential for heat buildup. The wiring should be evaluated for condition and safety concerns. Hire an electrician for an evaluation and to make repairs as needed.

Cloth Sheathed Wiring

Cloth sheathed cable is an early form of “NM” or non-metallic cable. Unlike modern, so-called “Romex” NM wiring, the outer casing is a cloth braid. It was installed primarily from the 1930s through the 1960s. It is almost always a 2-wire system and cannot be grounded. It is rubber insulated and shares some of the same vulnerability to physical damage as knob and tube.

While cloth sheathed wiring does not warrant the same level of concern as knob and tube, it should always be inspected carefully where visible. Damage or signs of overheating must be reported, and when in doubt recommend a further evaluation.

There is cloth sheathed wiring present. Cloth wrapped wiring is one of the early forms of branch circuit wiring methods. This is a potential safety hazard if the insulation degrades or breaks, leaving areas of the wiring exposed. Hire an electrician for an evaluation and to make repairs as needed.

There are loose or damaged cover plates. This is a safety concern that defeats the enclosure’s fire rating and permits contact with energized components. Secure or replace the cover plates.

There are missing cover plates. This is a safety concern that defeats the enclosure’s fire rating and permits contact with energized components. Secure or replace the cover plates.

There are missing junction box knockout covers. This is a safety concern that defeats the box’s fire rating and permits contact with energized components. Hire an electrician to make required repairs.

There are improperly secured junction boxes. This is a safety concern that can damage wire connections. Hire an electrician to make required repairs.

There are damaged or missing weather-rated covers. This is a shock hazard in wet areas. Install or replace the weather-rated cover.

Some sections of the wiring conduit are loose. This is a potential shock hazard. Hire an electrician to make required repairs.

The conduit is damaged, exposing the wires inside. This is a shock and a safety hazard. Hire an electrician to make required repairs.

There is exposed and unprotected wiring. This is a safety hazard. Hire an electrician to make required repairs.

There are loose or hanging wires. This is a safety hazard. Hire an electrician to make required repairs.

There are improperly secured wires at an appliance or electrical junction box. Safety standards require a retainer where wires enter a box or device. Hire an electrician to make required repairs.

The wire sheathing is damaged. This is a shock and fire hazard. Hire an electrician to make required repairs.

There are exposed branch circuit ends. All wire terminations must be in a permanently-accessible approved junction box, with a cover, for safety. This is a safety hazard. Hire an electrician to make required repairs.

There are exposed wire splices. This is a safety hazard. All wiring splices must be in an approved junction box with a proper cover and permanently accessible. Hire an electrician to make required repairs.

There is wiring installed outside that is not rated for the exterior. This is a safety hazard as the wire is vulnerable to deterioration. Hire an electrician to make required repairs.

There is wiring installed directly in the ground that is not rated for burial. This is a safety hazard as the wire is vulnerable to deterioration. Hire an electrician to make required repairs.

There is an extension cord being used as permanent wiring. This is a safety hazard. Hire an electrician to make required repairs.

There is wiring installed in direct contact with metal HVAC ductwork. This is a safety hazard that could electrify the ducts. Hire an electrician to make required repairs.

There is wiring which is routed through the floor, a wall, or under a carpet. This is unsafe and is a fire and shock hazard. Hire an electrician to make required repairs.

There is wiring located too close to a heat source. Wires should have adequate clearance from any hot pipes, ducts, or flues. Hire an electrician to make required repairs.

Branch Circuits Limitation and Information Statements

Knob and tube wiring present, not as safe as modern wiring, engage qualified electrician to evaluate, budget for repairs/replacement: Older knob and tube wiring is present in the house; it is not as safe as more modern wiring. Many insurance companies will not issue homeowner insurance coverage if knob and tube wiring is part of the electrical distribution system. Even if the accessible knob and tube wiring appears to be abandoned or dead, this does not preclude the distinct possibility that some of this wiring may still be in use in inaccessible areas such as within wall cavities. Have the knob and tube wiring evaluated by a qualified electrician, and budget as needed for repairs or replacement.

Single strand aluminum branch wiring present, repairs evident: Single strand aluminum branch wiring is present; repairs are evident. Where visible, the methods used appear to comply with the recommendations of the Consumer Product Safety Commission (CPSC) for safe and permanent remediation. We strongly encourage you to obtain all relevant repair invoices and approved work permits issued by the local building authority.

Grounding/Bonding

Grounding vs. Bonding: what’s the difference? This is arguably the most misunderstood basic concept in the residential wiring systems we evaluate everyday. Many professionals, including home inspectors and even electricians, use the terms interchangeably. But they are two very different things, both of which are essential to electrical safety.

Most inspectors would likely tell you that a properly-installed ground rod protects you against shocks if an ungrounded (hot) wire touches a metal portion of the system. But it’s correct system Bonding that causes the OCPD (breaker or fuse) to trip and clear the ground fault, preventing electrocution. Additionally, people say “electricity always seeks a path to ground.” In reality, the destination for the electricity is back to its source, usually the utility transformer. Because a properly-wired system has many neutral connections to ground, the earth is just one path back to the source.

The primary role of grounding is not to ensure that breakers will trip and prevent electrocution hazards. When it comes to ground faults, the contact resistance of a buried grounding electrode is quite high. Very little fault current returns to the power supply if the earth is the only fault current return path. The result is that the circuit breaker or fuse won’t open. All the metal parts associated with the electrical installation, metal piping, and structural building steel will become and remain energized.

Grounding stabilizes the system voltage, and reduces damage from transient overvoltage caused by lightning strikes. It also has the benefit of fire reduction by reducing voltage stress on electrical insulation and components, and preventing arcs. Failing to ground the system’s metal parts can result in high voltage on the metal parts from an indirect lightning strike. This voltage can seek a path to the earth within the building, possibly resulting in a fire and/or electric shock.

The ground wire is loose or disconnected. The ground system is a fundamental safety feature of the electrical installation, and will not work unless the connections are intact. Hire an electrician to make required repairs.

The ground wire has a break or cut. The ground system is a fundamental safety feature of the electrical installation, and will not work unless the connections are intact. Hire an electrician to make required repairs.

The ground wire is damaged. The ground system is a fundamental safety feature of the electrical installation, and will not work unless the connections are intact. Hire an electrician to make required repairs.

Bonding is the process of connecting all electrical devices together to ensure that an OCPD (breaker or fuse) will open if an ungrounded (hot) conductor touches a metal surface associated with the system. The Code requires an electrically continuous, low resistance path from every part of the system back to the Service Equipment. It must be installed in a manner to facilitate the operation of an OCPD if a ground fault occurs. At the Service, these connections terminate on the Neutral Bus, which returns to the electrical source. To stabilize system voltage the neutral is also grounded.

There is a missing bond clamp. This is a safety concern which may create an interruption in the continuous bonding of the electrical system. Hire an electrician to make required repairs.

There is a loose bond clamp. This is a safety concern which may create an interruption in the continuous bonding of the electrical system. Hire an electrician to make required repairs.

There is a broken or deteriorated bond clamp. This is a safety concern which may create an interruption in the continuous bonding of the electrical system. Hire an electrician to make required repairs.

The bonding is missing at the cold and hot water pipes entering and exiting the water heater. Bonding is required to ensure the safe continuity of the plumbing bond system. Hire an electrician to make required repairs.

The bonding is missing at the CSST gas pipe installation. Corrugated Stainless Steel Tubing requires bonding other than at the appliance connections to protect against damage during lightning storms. Hire an electrician to make required repairs.

Grounding/Bonding Limitation and Information Statements

Terminates below grade, driven grounding rod not verified: The ground wire terminates below grade. The presence of a driven grounding rod cannot be verified.

Receptacles

Receptacles are what are commonly referred to as outlets, but the correct term is receptacle. The definition of “outlet” in the NEC is a point on the wiring system where current is taken to supply equipment, i.e. a lighting fixture box or a receptacle. Both are “outlets.” Receptacles take a lot of physical use, and are a more temporary electrical connection as they rely on inserting and withdrawing plugs to complete the circuit. Additionally, older style 2-prong receptacles are still in widespread use, and often are adapted or even updated in an unsafe manner. The Standards require that we test a representative sampling of receptacles.

Inspect all readily-accessible receptacles using your 3-prong GFCI tester. Connect a 2-to-3 prong adapter when necessary. Report all damaged, inoperative, or mis-wired receptacles, scorch marks, missing or damaged cover plates, loose installations, and intermittent connections. The use of installed 2-3 prong adapters must be noted. Test all GFCIs after confirming that you are not shutting off a critical system, e.g. a freezer, that you can’t reset. AFCIs should only be tested once you are sure they will not shut off an important device such as an alarm clock or computer.

The receptacle is inoperative. The cause cannot be determined at the time of the inspection. Hire an electrician for an evaluation and to make repairs as needed.

The receptacle is damaged. This is a safety hazard. Hire an electrician to replace the receptacle.

The receptacle is loose in the wall or in its junction box. This is a safety hazard that can damage or loosen the wire connections. Hire an electrician to make required repairs.

The receptacle is not mounted flush with the wall surface. This is a fire and shock hazard. Hire an electrician to replace the receptacle.

The receptacle is painted. This can affect proper electrical contact and is a safety concern. Hire an electrician to replace the receptacle.

The receptacle is worn or loose. Older receptacles that have been heavily used can become defective and prevent adequate electrical connection. This is a fire and shock hazard. Hire an electrician to replace the receptacle.

There is an ungrounded 3-prong receptacle. This is a safety hazard that gives the false appearance that there is proper electrical protection. Hire an electrician for an evaluation and to make repairs as needed.

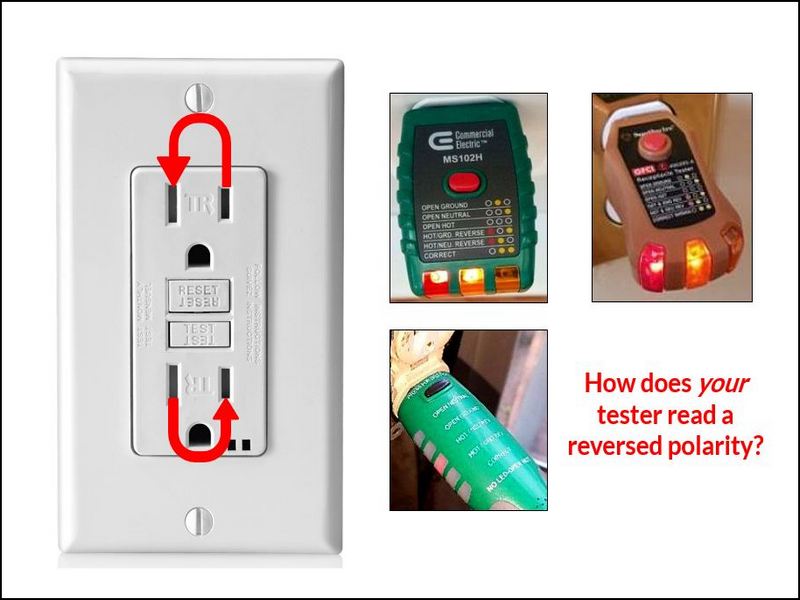

The receptacle has reversed polarity. This is a shock hazard that can also damage devices that are plugged in. Hire an electrician to make required repairs.

The receptacle has an open neutral connection. This is a shock hazard. Hire an electrician to make required repairs.

The receptacle has a broken pin in the slot. This is a shock hazard. Hire an electrician to make required repairs.

Three prong adapters are in use at two-prong receptacles. This defeats the purpose of the third prong, which is to prevent shocks when the appliance is defective. Hire an electrician to make required repairs.

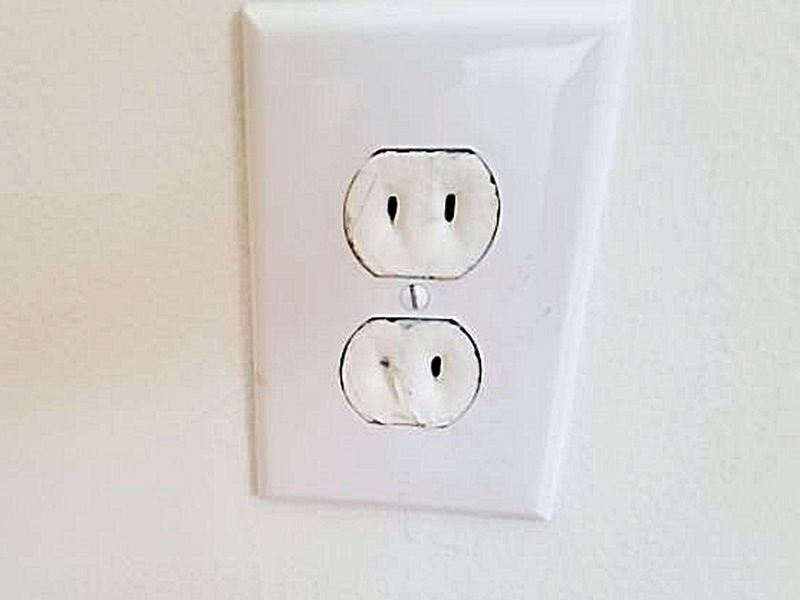

The receptacle shows signs of overheating. This indicates a potential problem with the circuit or the receptacle. Hire an electrician for an evaluation and to make repairs as needed.

Before testing any GFCI receptacle or downstream protected receptacle, ensure that you will be able to reset the device. Sometimes downstream receptacles in garages are served by a GFCI that is not accessible. If that circuit powers a freezer the result could be an expensive loss of food.

Most adopted code models allow a 2-prong receptacle to be replaced by a GFCI receptacle. GFCI receptacles DO NOT require a 3rd. pin ground connection to operate correctly. However, your tester generally will not function properly in an ungrounded GFCI. Additionally, any such ungrounded GFCI receptacle must be labeled “No equipment ground.”

There is a standard receptacle installed in a location that currently mandates a GFCI device. While this may not have been required at installation, it is a safety hazard. Hire an electrician to replace the receptacle.

The GFCI receptacle has power, but it doesn’t trip when the test button is pushed. This is a safety hazard. Hire an electrician to replace the receptacle.

The electricity at the GFCI receptacle remains on after the test button has been tripped. This is a safety hazard. Hire an electrician to replace the receptacle.

The GFCI receptacle will not reset after testing. The circuit will remain de-energized. Hire an electrician to replace the receptacle.

The receptacle is missing a cover plate. Missing covers are a shock hazard. Replace the cover plate.

The receptacle’s cover plate is damaged. Damaged covers are a shock hazard. Replace the cover plate.

The receptacle is in a wet area without a weather cover. This is a safety hazard. Install a weather cover.

The receptacle is in a wet area with a damaged weather cover. This is a safety hazard. Replace the cover.

The exterior receptacle weather cover is not a “full exposure” cover. This will not safely protect the receptacle from water penetration when devices are connected in an ongoing basis. Install or replace the weather-rated cover.

There is an receptacle installed in the floor without an appropriate weight bearing cover. This is hazardous as chair legs, table legs, or heels can break through the cover into the live contacts. Install a weight-bearing floor cover plate.

We are required by the SOP to inspect a “representative sampling” of electrical receptacles. This inspection is visual, and is also performed using a receptacle tester. We use a tester in both “regular” and GFCI receptacles.

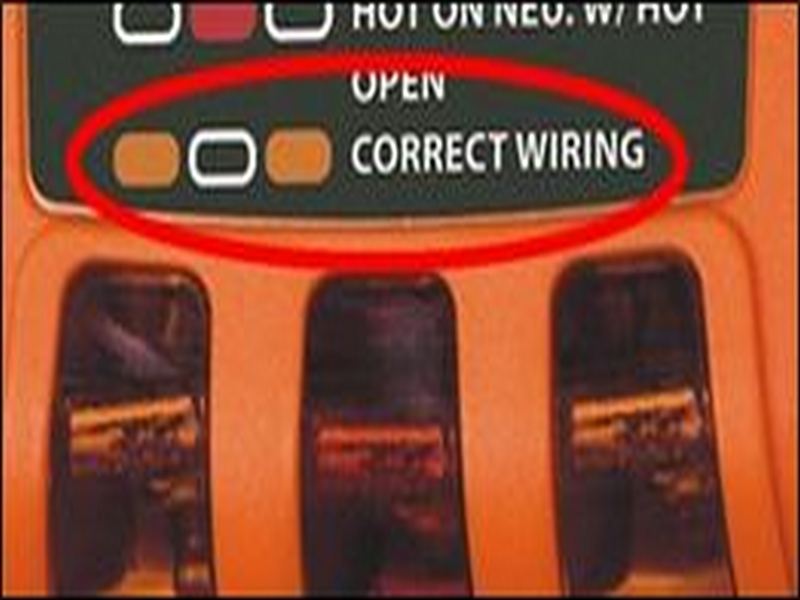

There are many different testers in use.

The various testers use different light combinations to indicate specific conditions. It is essential that you read your device’s legend and understand what it’s telling you.

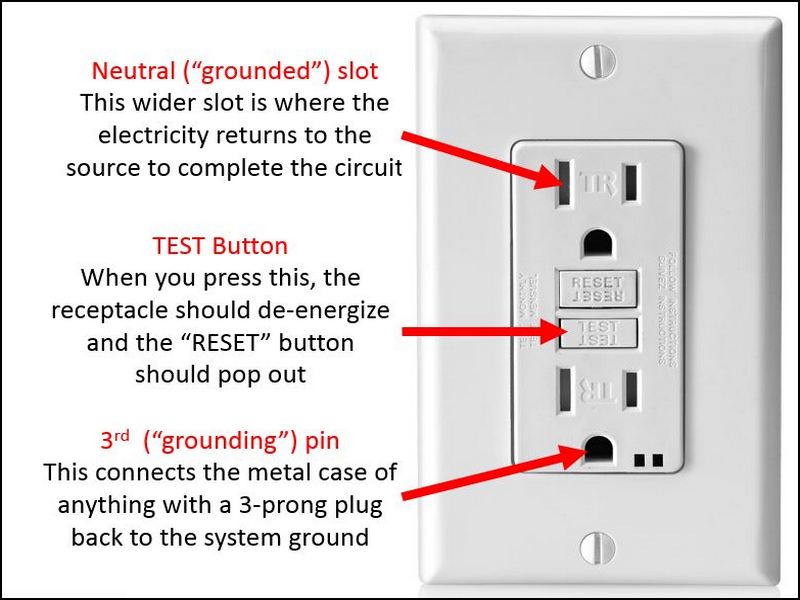

Testing GFCI Receptacles

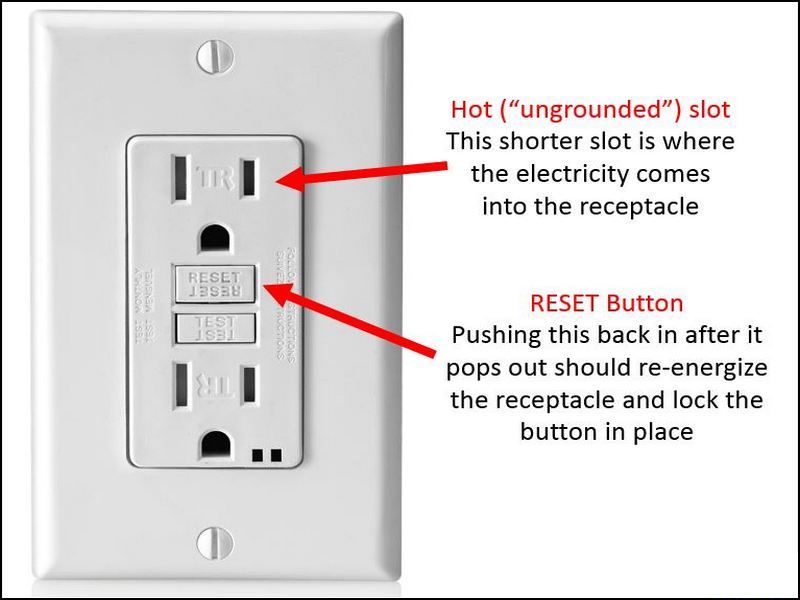

Insert the tester to evaluate the receptacle. You then press the tester’s “TEST” button. The GFCI should de-energize and its “RESET” button should pop out. Pressing the receptacle’s RESET button should lock it in place and re-energize the receptacle.

Ungrounded 3-Prong Receptacles

This means that the 3rd. “grounded” pin is not connected. A GFCI receptacle DOES NOT require a grounded 3rd. pin to operate correctly. In most jurisdictions this an acceptable fix for 2-prong receptacles. However, in this case the receptacle must be marked “No Equipment Ground.”

Most testers cannot properly test an ungrounded receptacle’s GFCI function. The tester’s lights may light up, but the receptacle will not trip and de-energize. Instead, follow normal homeowner test procedure. Use the receptacle‘s “TEST” button. Confirm that the receptacle has de-energized and the “RESET” button has popped out. Press the “RESET” button; it should lock in place. Use the tester to ensure the receptacle is re-energized.

Reversed Polarity Receptacles

In this error, the black (hot) and white (neutral) wires are attached to the wrong slots. They are “reversed” from the correct connections. This is a shock hazard. It can also damage electronic equipment.

Receptacles Limitation and Information Statements

2-prong receptacles do not provide for separate ground connection, consider hiring electrician to convert to 3-prong receptacles: There are 2-prong receptacles which do not provide for a separate ground connection. Consider hiring an electrician to convert the 2-prong receptacles to 3-prong receptacles.

AFCI devices are for electrical safety protection to interrupt power to a circuit if electrical arcing occurs, no AFCI testing: AFCI devices are for electrical safety protection to interrupt power to a circuit if electrical arcing occurs. We do not test AFCIs because receptacles often are connected to clocks, PCs or other electronic equipment.

Test GFCI devices regularly to ensure proper working order, most GFCI manufacturers recommend monthly testing, replace if not working properly: Test GFCI devices regularly to ensure proper working order. Most GFCI manufacturers recommend testing monthly. If any GFCI device does not test or reset properly, it should be replaced. GFCI devices monitor electrical current through a circuit. If electrical current is not balanced, there is a current leakage, also referred to as a “ground fault.” GFCIs devices sense current leakages as small as .0005 Amps. If the GFCI device senses a ground fault, the GFCI device will terminate the current in approximately 1/40 of a second, fast enough to prevent personal injury. To test GFCI devices, push the “test” button, which should pop the “reset” button and terminate power. To restore power, push the “reset” button. To test GFCI circuit breakers in electrical panels, push the “test” button. The circuit breaker should switch off and terminate power to the circuit. To restore power, switch the circuit breaker off and then on.

Limited number of electrical receptacles throughout the house, not unusual in older homes, consider hiring electrician to install additional receptacles: There are a limited number of electrical receptacles throughout the house, which is not unusual in older homes. Consider hiring an electrician to install additional receptacles for convenience and safety.

Exterior receptacles which are not GFCI-protected, help to prevent shock hazards, consider hiring electrician to convert to GFCI receptacles: There are exterior receptacles which are not GFCI-protected. GFCI receptacles help to prevent shock hazards. However, in older homes, GFCI protection was not required at locations which otherwise would be required according to present industry standards. Consider hiring an electrician to convert the receptacles to GFCI receptacles.

GFCI protection in older homes not installed at many locations required by current standard, recommend upgrading to GFCI: In older homes, GFCI protection was not installed at many locations required by current industry standards, e.g., kitchen counters and kitchen islands, bathrooms, exterior. We recommend upgrading such receptacles to GFCI. Upgrading is inexpensive and can prevent shock hazards.

Switches

We probably operate the switches in our homes more than any other part of the electrical system. It’s easy to take them for granted. If a light bulb flickers, most homeowners would blame the bulb or the lamp. As home inspectors we know that it could easily be the switch. It’s precisely because switches get used so often that they can wear out. We also know that a switch can be installed improperly, whether it’s a 3-way switch, a dimmer, or a light switch for the bathroom.

Operate and inspect switches for condition; there should be no damage to the switch or the cover plate, no intermittent action, signs of overheating, looseness, or buzzing. Any switch in a wet area must have a weather-rated cover. When a light is controlled by 2 switches, a “3-way” installation, flipping either switch in any order should affect the light. Report switches too close to tubs and showers, taped-over, or inoperative switches. Ceiling fans cannot be on standard dimmer switches: it’s the one instance where you may wish to remove a cover plate and check the label.

The switch is damaged. This is a safety hazard. Hire an electrician to replace the switch.

The switch is loose in its box. This is a safety hazard. Hire an electrician to make required repairs.

The switch is missing or has not been installed. This affects proper function. Hire an electrician to replace the switch.

The switch has a damaged cover plate. Cover plates are required to prevent shock hazards and to maintain the junction box’s safety rating. Replace the cover plate.

The switch is missing a cover plate. Cover plates are required to prevent shock hazards and to maintain the junction box’s safety rating. Replace the cover plate.

The switch shows evidence of overheating. This is a shock hazard and safety concern. Hire an electrician for an evaluation and to make repairs as needed.

A switch has been taped over to prevent its use. The reason for this is not known. Hire an electrician for an evaluation and to make repairs as needed.

The switch is missing at the stairway. Switches are required at the top and bottom of all interior stairs to allow for proper illumination before use. Hire an electrician to make required repairs.

The ceiling fan switch is a dimmer. Most dimmers are rated only for incandescent lights and not for fan motors. Hire an electrician to make required repairs.

The switch is located too close to a tub or shower area. This is a shock hazard. Hire an electrician to make required repairs.

The switch is located in or near a wet area, but the switch does not have a weather cover. This is a safety hazard. Hire an electrician to make required repairs.

The switch’s weather rated cover is damaged. This is a shock hazard. Hire an electrician to make required repairs.

Switches Limitation and Information Statements

Wall switches present for uninstalled fixtures: Wall switches are present that appear to be intended to control secondary light fixtures that are not installed yet, e.g., a ceiling fan light. Switches that are not currently connected to a functioning device cannot be tested. This limits the inspection.

Electronic switch/dimmer lighting controls, operation beyond scope, tested switches for “on/off” function: This house is equipped with several electronic switch/dimmer lighting controls. These are specialized systems which often are installed “after-market.” Their operation is beyond the scope of a home inspection. We tested the switches only for “on/off” function.

Low voltage lighting for landscaping or other areas, operation beyond scope: The property is equipped with low voltage lighting for landscaping or other areas. Low voltage lighting systems frequently are controlled by timers or photo-sensors and are outside the scope of a home inspection.

Switches with push buttons, consider hiring electrician to install modern push button models available for historic renovations: There are switches with push buttons. Such switches generally are considered obsolete and may not be as reliable as newer switches. Consider hiring an electrician to install modern push button models which are available for historic renovations.

Fixtures

The component “Electrical – Fixtures” includes lights (luminaires), ceiling fans, and doorbells. The concerns here are fairly straightforward. The permanently-installed light fixture comes on, or it doesn’t. It is installed properly with an intact globe, or it isn’t. The same is true for doorbells and ceiling fans.

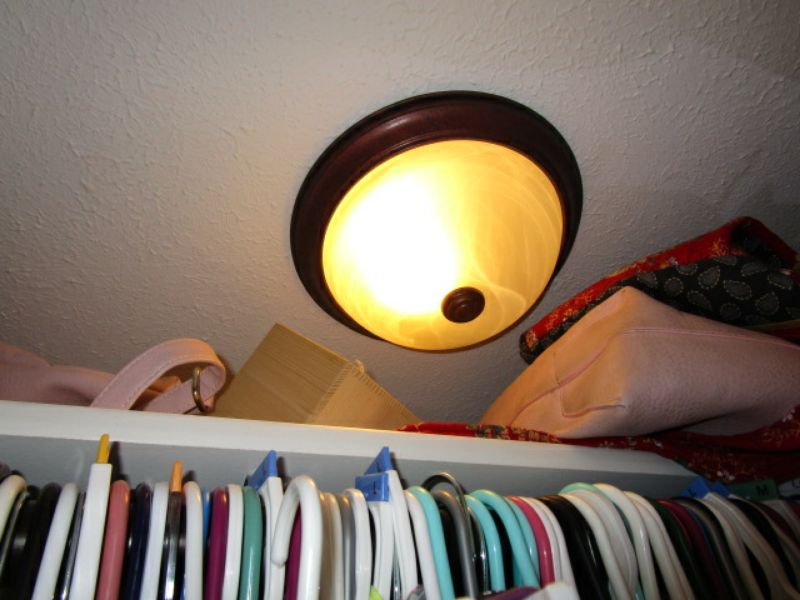

Inspect for operative lights, ceiling fans, and doorbells. Light fixtures should not be loose or damaged. Ensure that proper clearances are observed between incandescent bulbs and flammables, especially in closets. Any luminaire above a tub or shower should be a sealed fixture. Fans should be quiet and not wobble. Doorbells should ring and their buttons should be intact.

The light fixture is inoperative. This can be a safety hazard. Repair or replace the fixture.

The light bulb is exposed. This is a safety hazard. Repair or replace the fixture.

The light fixture is loose. This is a safety hazard that can damage the electrical connections. Repair or replace the fixture.

The light fixture is damaged. This is a safety hazard. Repair or replace the fixture.

The light fixture’s glass globe or panel is damaged or missing. This is a safety hazard. Replace the globe or panel.

The closet’s incandescent light fixture lacks proper clearances to potentially combustible items. This is a fire hazard. Relocate the fixture to provide a minimum 12″ clearance, or replace it with a fluorescent or LED fixture.

The light fixture above the tub or shower area is unsealed. This is a safety hazard. Repair or replace the fixture.

The doorbell is inoperative. Repair or replace the doorbell.

Fixtures Limitation and Information Statements

Blank ceiling cover plates present with no fixture: Blank cover plates are present at the ceiling where no fixtures are installed. Switches that are not currently connected to a functioning device cannot be tested. This limits the inspection.

Smoke Detectors

Smoke detector/alarms are a key part of any home’s safety equipment. Nearly 2/3 of all residential fire deaths occur when there is not a working smoke detector present. 21% of those deaths occur when an alarm is present but not working. This points out the importance of inspecting and reporting as thoroughly as possible. Additionally, jurisdictions are well aware of these statistics, and are updating relevant laws. It’s imperative to be familiar with your state and local requirements.

Before testing any detectors, confirm that they are not actively connected to an alarm system; this could cause a false alarm response from the fire department. Inspect for any loose, damaged, or missing detectors. Report any units that are 10 years old or older based on their appearance or the home’s age. Use the available Limitation Statement and/or any state-mandated wording as needed.

There are missing smoke detectors. This is a safety issue. There should be at least one functional smoke detector on each level of the house. Replace the smoke detector.

The smoke detector is inoperative. This is a safety issue. There should be at least one functional smoke detector on each level of the house for safety. Replace the smoke detector.

The smoke detector is loose or hanging. This can affect proper function. Repair or replace the detector.

The smoke detectors are 10+ years old and beyond their life expectancy. This is a safety hazard. Replace the smoke detectors.

Smoke Detectors Limitation and Information Statements

Smoke alarm(s) operational, not tested with smoke: Smoke alarm(s) appears to be operational, i.e., the test button(s) works when pushed. However, clients should note that this action only tests the battery of the unit(s). Testing of the actual smoke detector mechanism requires the use of smoke, which is outside the scope of this inspection. Additionally, only a representative sampling of units are tested even if “smoke sticks” are employed. Smoke alarms which utilize batteries as either a primary or secondary power source should have the batteries replaced twice per year. The smoke detector mechanism of these alarms only has a life span of 10 years, requiring replacement of the entire smoke alarm after this time. When replaced, combination photo-electric and ionization units should be used to protect against smoldering fires and flaming fires, respectively. Alarms presently are being manufactured with enclosed 10 year batteries. This prevents frequent battery replacement and acts a reminder to replace the entire alarm when the battery dies.

CO Detectors

Carbon Monoxide (CO) detectors should be installed in any home that has a fireplace or a fossil fuel burning appliance, e.g. a gas water heater, gas furnace, fireplace insert, cooking appliance, or space heater. This odorless, tasteless, and colorless gas is created as the byproduct of incomplete fossil fuel or wood combustion. The NFPA reports that fire departments respond to over 70,000 non-fire CO events annually, and that upwards of 200 deaths occur each year. As with smoke detectors, jurisdictions are well aware of these statistics and are updating relevant statutes. You must be familiar with the requirements in your area.

Ensure that any CO detectors present are not connected to an active alarm system that would summon the fire department. Activate any accessible test buttons. Report if there are no CO detectors in the home, and any unresponsive, missing, hanging, or damaged units. Use the mandated state language as needed.

There are no carbon monoxide detectors. The home has fuel burning appliances or components which can emit CO in their exhaust gases. This is a safety issue. Install a carbon monoxide detector.

The carbon monoxide detector does not respond to the test button. This is a safety issue. Repair or replace the carbon monoxide detector.

CO Detectors Limitation and Information Statements

CO detectors essential in homes with burning fossil fuels, install detectors upon occupancy: Carbon monoxide detectors are essential in homes in which fossil fuel is burned. Install carbon monoxide detectors upon occupancy.

Plug-in CO detectors are installed, devices don’t always convey, install detectors upon occupancy: Plug-in carbon monoxide (CO) detectors are installed. These devices do not always convey with the property. CO detectors are essential in homes in which fossil fuel is burned. Ensure that properly-located and functioning CO detectors are present when you occupy the home.