- Inspect

- Insulation and vapor retarders in unfinished areas

- Ventilation and humidity control systems in attics and crawl spaces

- Mechanical ventilation systems

- Describe

- Insulation, vapor retarders, and humidity control systems in unfinished spaces

- Absence of insulation in unfinished spaces at conditioned surfaces

- Absence of humidity control measures in unfinished spaces

- Not required

- Mechanical systems which would require dismantling to inspect

- Powered systems which are turned off

Attic Insulation

Appropriate attic insulation can be the single largest factor in managing a home’s energy costs. 25% of a home’s generated heat can be lost through the roof, accounting for up to 60% of the total energy lost in cold weather. During summer in warm climates inadequate insulation can require 1/2 ton of cooling just to overcome the heat gain from a hot attic. Additionally, the thoroughness of the insulation matters. Gaps and bare spots can negate the upper ceilings’ overall R-value.

Safety comes first, but enter and inspect attics as completely as possible. Report displaced or missing insulation, thin areas, and coverage not up to current local requirements. Exposed flammable materials such as paper vapor barriers are notable, as are improperly-installed materials. The vapor barrier must be against the drywall or plaster and closest to the conditioned spaces. Newer top layers should not have an additional vapor barrier; loose or “unfaced” product should be installed. “Can” lights must have clearance from insulation unless you can confirm that they are”IC” rated. Look for damaged insulation, and be sure to connect the dots if you see water damage.

Insulation is missing in the attic. This affects energy efficiency. Install insulation in accordance with local guidelines.

The level of attic insulation is considered inadequate by today’s standards. Install insulation in accordance with local guidelines.

Insulation has been moved, leaving uninsulated areas. This affects energy efficiency. Install insulation in accordance with local guidelines.

Insulation is compressed or settled in the attic to an extent to which its effectiveness is compromised. This affects energy efficiency. Install additional insulation in accordance with local guidelines.

Insulation is damaged in the attic to an extent to which its effectiveness is compromised. This affects energy efficiency. Replace the insulation.

There is exposed flammable insulation present. The insulation is required to be protected using fire-rated materials. Replace the insulation or cover it with approved materials.

The attic insulation is installed with the vapor retarder exposed; the Kraft paper barrier is flammable and should be covered. Replace the insulation, or cover the exposed vapor barrier with approved materials.

The attic insulation is installed backwards with the vapor retarder exposed. The vapor barrier is required to be installed against the conditioned side of the ceiling to prevent the trapping of moisture. This is also a safety hazard. Reinstall or replace the insulation.

The insulation is adjacent to the recessed lighting fixtures. Unless the fixtures are of a newer design which permit contact with insulation, this is a fire hazard. Remove the insulation from the light fixtures.

There are water stains on the attic insulation. The insulation is dry at the time of the inspection. Identify sources of moisture and mitigate any water penetration.

There are water stains on the attic insulation. The insulation is wet at the time of the inspection. The cause of the water must be identified. Identify sources of moisture and mitigate any water penetration. Replace the insulation as needed.

Attic Insulation Limitation and Information Statements

Near/at end useful life, budget for replacement: The attic insulation is near or at the end of its useful life. We recommend establishing a budget to replace the attic insulation.

Past end useful life, budget for replacement: The attic insulation is past the end of its useful life. We recommend establishing a budget to replace the attic insulation.

Inadequate by current standards: The level of attic insulation is considered inadequate by current standards. Consider installing additional insulation in accordance with local guidelines to improve energy efficiency.

Interior Insulation

Interior insulation requirements vary by locale; you should be familiar with your area’s standards. Recent codes for all but the southern and southwest tier states require conditioned spaces to have insulated walls: R-10 for continuous (spray foam) and R-13 for between the studs. Northern tier states require higher values. Unconditioned basements may be insulated on the wall, or on the ceiling between the basement and conditioned spaces above. Foam must be covered for fire safety unless rated for exposure.

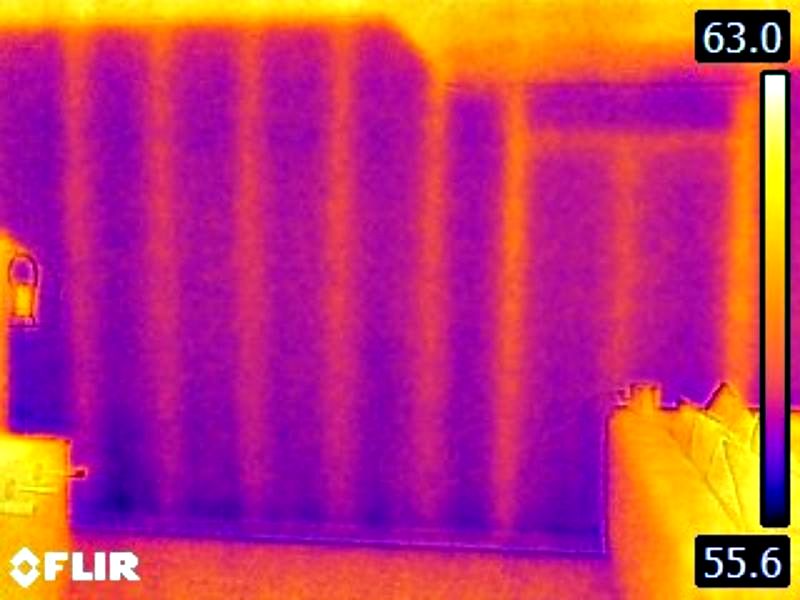

Inspect for loose, falling. damaged, and missing or inadequate insulation. Always report indications of moisture issues: don’t forget your Infrared scan! Remember to use a Limitation Statement when appropriate due to finished surfaces or access restrictions.

Insulation is missing. This affects energy efficiency. Install insulation in accordance with local guidelines.

The level of interior insulation is considered inadequate by today’s standards. Install additional insulation in accordance with local guidelines.

There is loose or falling insulation. This affects energy efficiency. Install insulation in accordance with local guidelines.

Insulation is damaged to an extent to which its effectiveness is compromised. This affects energy efficiency. Replace the insulation.

There is exposed flammable insulation present. The insulation is required to be protected using fire-rated materials. Replace the insulation or cover it with approved materials.

The insulation is installed with the vapor retarder exposed; the Kraft paper barrier is flammable and should be covered. Replace the insulation, or cover the exposed vapor barrier with approved materials.

There are water stains on the insulation. The insulation is dry at the time of the inspection. Identify sources of moisture and mitigate any water penetration.

There are water stains on the insulation. The insulation is wet at the time of the inspection. The cause of the water must be identified. Identify sources of moisture and mitigate any water penetration. Replace the insulation as needed.

Interior Insulation Limitation and Information Statements

Near/at end useful life, budget for replacement: The interior insulation is near or at the end of its useful life. We recommend establishing a budget to replace the basement insulation.

Past end useful life, budget for replacement: The interior insulation is past the end of its useful life. We recommend establishing a budget to replace the basement insulation.

Crawl Space Insulation

An unconditioned, vented crawl space can create significant heating and cooling challenges for a home. Insulation can help prevent winter heat loss and higher costs. In humid climates, the vapor barrier on properly-installed insulation reduces the AC system’s work load in the summer. “Closed” and “Closed and Conditioned” crawl spaces are becoming more common, and are being addressed in the codes. It is important to understand how these systems, installed in high-humidity areas, affect the use of insulation. See the information in the “Humidity Control” component.

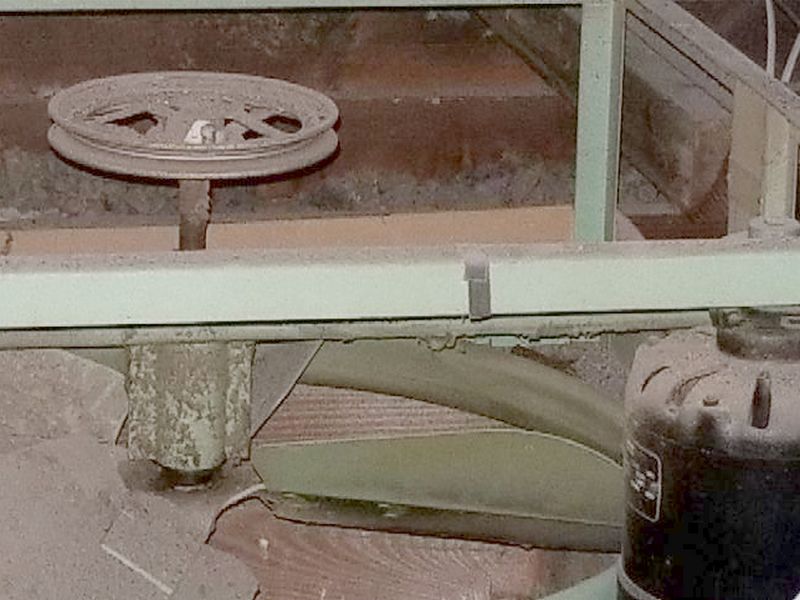

Always report missing crawl space insulation, regardless of the system in place. Inspect for inadequate levels of insulation, gaps on the walls or overhead sub-floor, unsecured and/or falling materials, and damage. Water stains or damage, whether wet or dry, must be noted.

Insulation is missing in the crawl space. This affects energy efficiency. Install insulation in accordance with local guidelines.

The overhead sub-floor inside the crawl space is not insulated. While this may have been acceptable when the house was constructed it affects energy efficiency. Install insulation in accordance with local guidelines.

There is loose or falling insulation inside the crawl space. This affects energy efficiency. Install insulation in accordance with local guidelines.

Insulation is damaged in the crawl space to an extent to which its effectiveness is compromised. This affects energy efficiency. Replace the insulation.

The level of crawl space insulation is considered inadequate by today’s standards. Install additional insulation in accordance with local guidelines.

The crawl space insulation is installed with the vapor retarder on the wrong side. This can allow moisture to condense within the insulation, reducing its effectiveness and promoting mold/mildew growth. Reinstall or replace the insulation.

The exterior foundation wall insulation is installed in contact with the wall frame. This condition will encourage pest infestation, and may trap moisture against the wood members. Remove the insulation from the wall frame.

There are water stains on the crawl space insulation. The insulation is dry at the time of the inspection. Identify sources of moisture and mitigate any water penetration.

There are water stains on the crawl space insulation. The insulation is wet at the time of the inspection. The cause of the water must be identified. Identify sources of moisture and mitigate any water penetration. Replace the insulation as needed.

Loose cellulose is installed as a crawl space insulation. This is an inappropriate material. It does not allow for a vapor barrier in a vented crawl space, and is intolerant or moisture. Replace the insulation.

Crawl Space Insulation Limitation and Information Statements

Near/at end useful life, budget for replacement: The crawl space insulation is near or at the end of its useful life. We recommend establishing a budget to replace the crawl space insulation.

Past end useful life, budget for replacement: The crawl space insulation is past the end of its useful life. We recommend establishing a budget to replace the crawl space insulation.

Ventilation

Ventilation in a home is important for controlling humidity, temperature, and providing adequate healthy indoor air. Older houses were not “tight.” Air exchanges took place through the openings inherent in the building’s envelope. Passive venting kept attic temperatures and humidity seasonally appropriate. New, much tighter, well-insulated buildings must use mechanical means to achieve indoor air quality requirements. Air-to-Air and Heat Recovery Ventilators (HRV), as well as Energy Recovery Ventilators (ERV) are used to maintain a healthy interior environment without running up HVAC operating costs.

Inspect for the basics: does the attic have balanced ventilation, e.g. ridge and soffit vents? Power vents should be tested if possible. “Whole house” fans must not be on automatic controls. Are full bathrooms and cooking areas provided with quiet, operative ventilators in good condition? Do all vents exhaust to the exterior? Are all exterior vent terminations pest-entry proof? We only inspect HRV and ERV units with the homeowner controls. Look for damage, improperly-installed filters, etc.

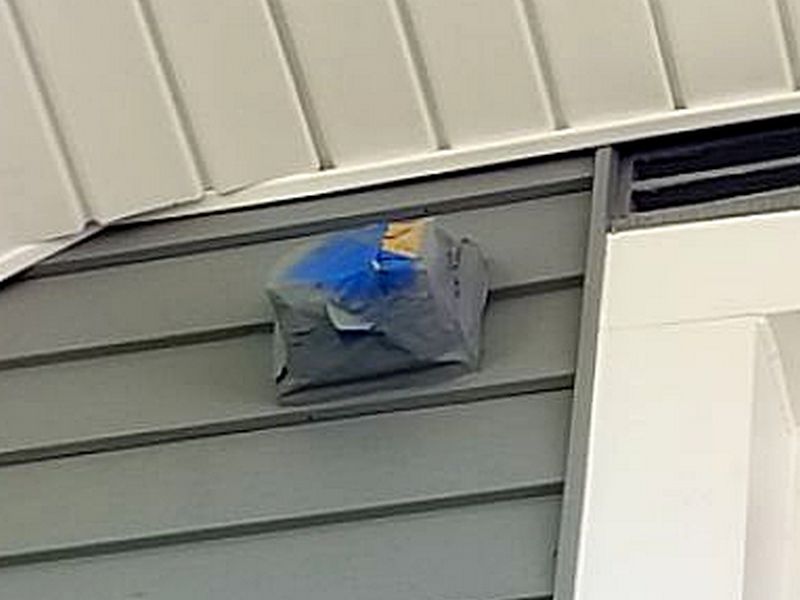

The fan exhausts to the attic instead of the exterior. This will increase moisture levels and mold/mildew issues. Reroute the discharge to the exterior away from the structure.

The fan exhausts to the crawl space instead of the exterior. This will increase moisture levels and mold/mildew issues. Reroute the discharge to the exterior away from the structure.

The fan exhausts to the garage instead of the exterior. This will increase moisture levels and mold/mildew issues. Reroute the discharge to the exterior away from the structure.

The exhaust vent is too close to the outside grade. This can allow snow or debris to block the vent. Raise the vent to at least 1′ above the grade.

The exhaust fan exterior hood is missing or damaged. This permits pest intrusion. Replace the exterior hood.

The exhaust fan exterior hood is blocked. This affects proper operation and is a safety concern. Clear the hood.

The exhaust fan duct is damaged. This permits moisture into the house. Repair or replace the duct.

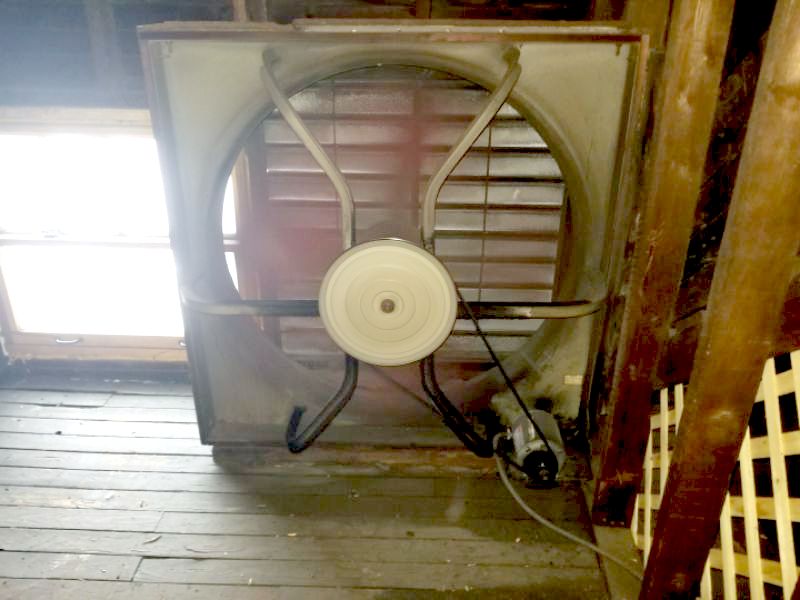

The whole house fan is inoperative. Repair or replace the fan for proper function.

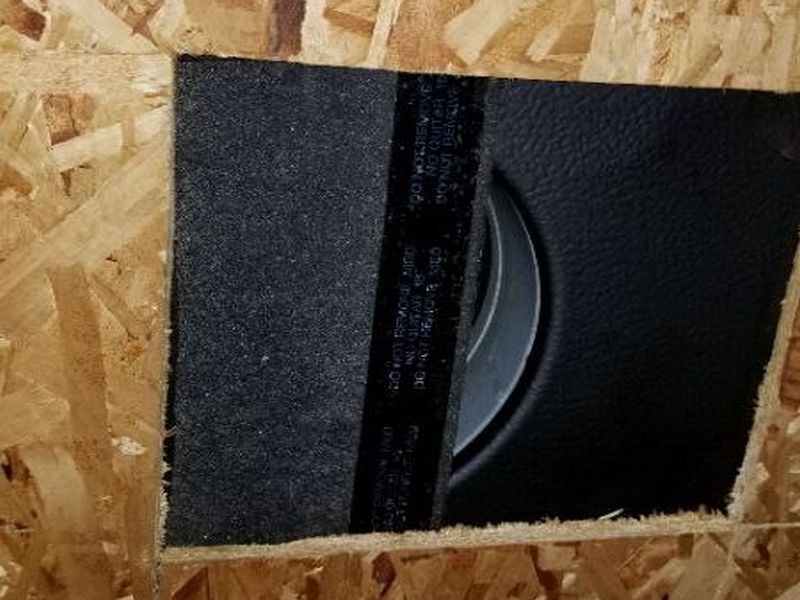

The whole house fan protective shroud is missing. This is a safety hazard. Install or replace the shroud.

The whole house fan has been installed in an unworkmanlike manner. This is a safety and reliability concern. Reinstall the fan.

There is a timer or thermostatically-controlled whole house fan in the attic. This is no longer permitted. The fan can depressurize the house and cause combustion appliances to backdraft if it operates without windows open to provide make-up air. Remove the fan’s automatic control so that manual operation is required.

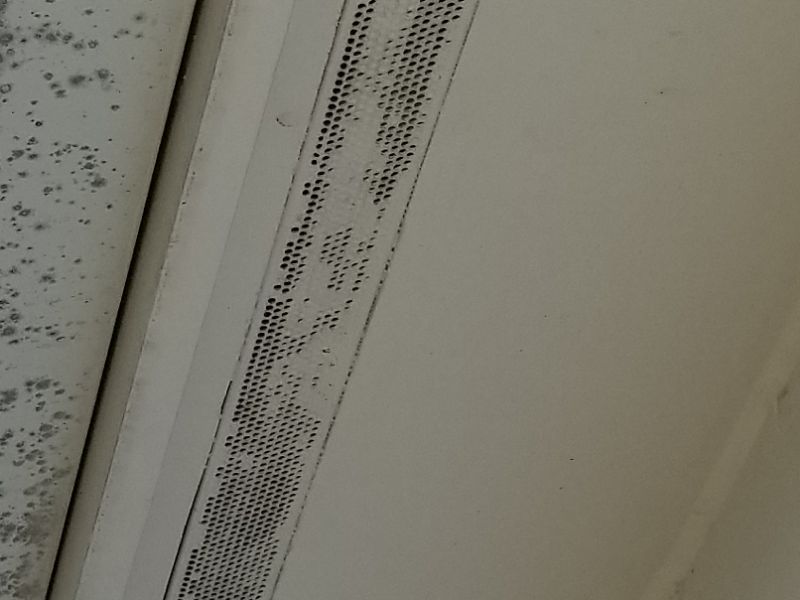

There are blocked attic ridge vents. This permits heat and moisture buildup. Clear the vents.

There are blocked attic gable vents. This permits heat and moisture buildup. Clear the vents.

There are blocked attic roof vents. This permits heat and moisture buildup. Clear the vents.

The exterior soffit vent screens have been painted over. This makes them ineffective, and permits heat and moisture buildup. Clear or replace the vent screens.

There are missing soffit vent baffles in the attic. This permits insulation to block the vents and cause heat and moisture buildup. Repair or replace the baffles.

There is damaged attic vent screening. This permits animal and pest entry. Replace the screening.

There is damaged crawl space vent screening. This permits animal and pest entry. Replace the screening.

Ventilation Limitation and Information Statements

No ventilation source, no evidence of moisture issues, consider installing ventilation: The attic area has no ventilation source but there is no evidence of moisture issues that occur in attics lacking ventilation. Due to the nature of older construction, there may be enough small openings in the attic area to provide minimal ventilation. Consider installing more attic ventilation for energy conservation.

Whole house fan installed to lower interior and attic temperatures during summer months: The home includes a whole house fan designed to lower interior and attic temperatures during summer months. Whole house fans require intake air (usually open windows) and an exhaust vent in the attic to ensure proper operation. The fan switch should be located in an area outside of normal reach to ensure that it is not accidentally activated. The fan switch should not be activated when windows are closed nor should the switch employ an “automatic on” feature, which would allow the house to become depressurized, causing combustion by-products from heating appliances (e.g., water heater, fireplace, etc.) to enter the home. During winter months, place insulation over the fan inside the attic to reduce heat loss. It is also important to install carbon monoxide detectors in homes with whole house fans and fossil fuel appliances or fireplaces.

Windows provide attic ventilation but need to be manually operated to provide attic ventilation, consider installing permanent attic vents: Windows provide attic ventilation. Such windows need to be manually operated to provide adequate attic ventilation. Consider installing permanent attic vents, such as soffit or gable vents, which remain open and protect against the entry of rain and snow.

High rise residential dwellings typically have passive venting systems to provide source of fresh air/allow discharge of stale air and odors: High rise residential dwellings typically have passive venting systems to provide a source of fresh air and to allow the discharge of stale air and odors. This is needed for a healthy air exchange within the living space. Rooms such as bathrooms and kitchen need operative venting for this to be effective. Be sure the venting grills are present, open, and clean of lint and debris.

Humidity Control

Humidity control is essential for a healthy indoor environment as well as energy efficiency. Building Science has significantly changed our understanding of how this is best achieved in warm, humid climates. For those areas, venting a crawl space to the exterior, with or without a vapor retarder on the ground, is more likely to cause chronic humidity issues. “Closed” and “closed and conditioned” crawl spaces are a better solution. Traditional venting is still valid in dry climates. More information can be found at Crawlspaces.org .

Determine what humidity control approach is in place. Closed crawl spaces must be a complete commitment. A “partially” closed space will likely have more humidity problems than an open one. Look for incomplete details, e.g. insulation or vapor retarder gaps, missing weatherstripping, openings to the exterior. Any water intrusion into a closed system is a problem; basic exterior water controls must be in place. Overall, inspect for signs of chronic humidity: wood staining or growth, “stringy” fiberglass insulation, condensation overhead or on the vapor retarder.

There is not a crawl space vapor retarder. This will raise the humidity and is conducive to moisture related problems. Install a vapor retarder.

The crawl space vapor retarder does not cover all areas. This will raise the humidity and is conducive to moisture related problems. Install the vapor retarder over all areas.

The crawl space vapor retarder is damaged. This will raise the humidity and is conducive to moisture related problems. Repair or replace the vapor retarder.

The vapor retarder in the closed crawl space is in poor condition. This is a special concern in a closed system for preventing moisture related problems. Repair or replace the vapor retarder.

There are gaps in the closed crawl space’s wall insulation. This can allow outside air to enter and will have a negative effect on the overall performance of the system. Repair and seal the gaps.

The closed crawlspace’s wall insulation does not have a gap at the top to allow for a visual inspection of the foundation. This prevents a thorough inspection for wood destroying insects. Repair or replace the insulation as needed.

The conditioned crawl space’s access door does not have a weather-strip. This can allow exterior air to enter, which will diminish the system’s performance. Install a weather strip.

The crawl space is neither fully open or a “closed” system. This partial approach is likely to cause significant moisture related and environmental problems. Hire a contractor for an evaluation and to make repairs or upgrades as needed.

There is excessive moisture in the crawl space. This can cause structural damage and health concerns. The source of the moisture must be identified. Hire a contractor for an evaluation and to make repairs or upgrades as needed.

Humidity Control Limitation and Information Statements

Areas inaccessible/not visible due to height, design, materials: Some areas are inaccessible and/or not visible due to height, design and materials. Therefore, the inspection is limited.

Below-grade area includes exposed soil, may permit moisture/unwanted ground vapors: The below-grade area of the dwelling includes exposed soil. This condition may permit the migration of moisture and other unwanted ground vapors into the living area. This condition is conducive to pest infestation. Install a vapor retarder over the exposed soil.

No vapor retarder, no signs of excessive moisture, consider installing vapor retarder: The crawl space does not have a vapor retarder but there are no signs of excessive moisture. Consider installing a vapor retarder to continue to help keep the ground moisture away from house.

Close vents during colder months to avoid freezing temperatures below house, open vents during warmer months for cross-ventilation: Vents should be closed during colder months to avoid freezing temperatures below the house. Covers of rigid insulation or other materials can be used for such purpose. Vents should be reopened during warmer months for proper cross-ventilation.

Keep vents closed during summer months to keep warm, moist air out of crawl space: Foundation vents should be kept closed during the summer months to keep warm, moist air out of the crawl space and to reduce condensation on ductwork and other cool surfaces. Foundation vents can be opened during winter months to permit dryer winter air to ventilate the crawl space. Vents directly in front of plumbing pipes should always be kept closed to prevent freezing in winter months.

“Closed and conditioned” crawl space, to improve long-term moisture issues: This house features a “closed and conditioned” crawl space. This is an effort to improve long-term moisture issues that traditional approaches have not solved in humid areas. The closed and conditioned crawl space has no foundation vents or vents are sealed. The ground is covered and sealed at the walls and dehumidifiers occasionally are installed. HVAC registers are provided so that the space is heated and cooled. This makes the crawl space more of an extension of the conditioned interior of the home. While this appears to be a successful approach for many homes, there are some drawbacks. The primary one is that it is often not possible to inspect the walls and other spaces for evidence of insect activity. The space should be checked periodically for any leaks or water penetration. All of the basic surface water control features of good home construction must be maintained.

“Closed” crawl space, to improve long-term moisture issues: This house features a “closed” crawl space. This is an effort to improve long-term moisture issues that traditional approaches have not solved in humid areas. The closed crawl space has no foundation vents or vents are sealed. The ground is covered and sealed at the walls and dehumidifiers occasionally are installed. This makes the crawl space more of an extension of the conditioned interior of the home. While this appears to be a successful approach for many homes, there are some drawbacks. The primary one is that it is often not possible to inspect the walls and other spaces for evidence of insect activity. The space should be checked periodically for any leaks or water penetration. All of the basic surface water control features of good home construction must be maintained.

Crawl space vents installed in foundation walls permit moisture to be vented out of crawl space, keep vents open: Crawl space vents installed in the foundation walls permit moisture to be properly vented out of the crawl space. Trapped moisture promotes mold and mildew and could eventually result in structural deterioration. Therefore, it is important to keep vents open and unobstructed.