In the component “Branch Circuits” we are considering the actual wiring; the conductors that carry electricity throughout a home. Wiring systems and materials have evolved considerably over the years. Unless you only inspect new construction, you are very likely to encounter many installations that are now considered obsolete. In the “Red Flag” Wiring Systems section you will review several older systems that, at a minimum, must be inspected carefully or be recommended for a full evaluation.

Remember that the majority of the house wiring is not visible at all. It’s important to pay close attention where it is available, e.g. panels, attics, basements, crawlspaces. You may need to move aside some insulation, or get a bit closer, to see whether a defect is present. Maybe there’s knob & tube wiring under that loose fill, or that branch wire is actually marked “AL” or “Kaiser.”

Single Strand Aluminum Wiring

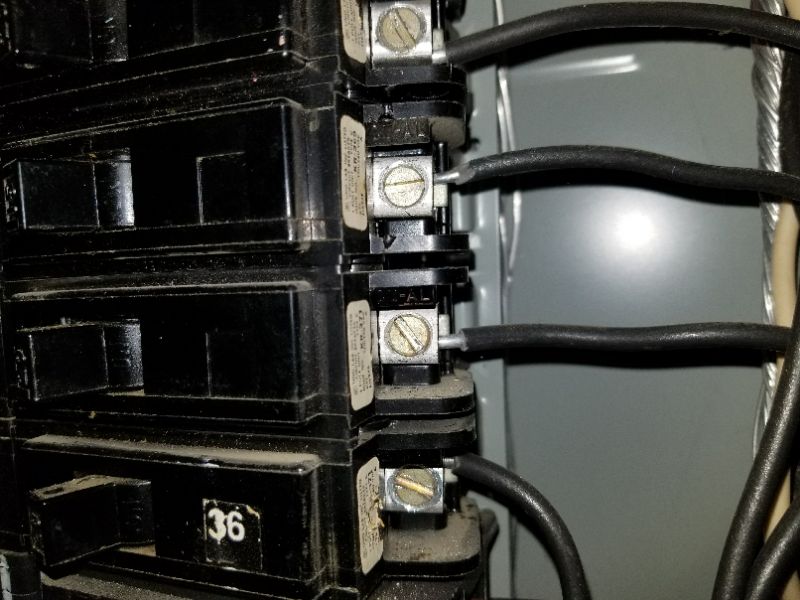

Single strand aluminum wiring in the lower 120 volt branch circuits should always be reported with a recommendation for further evaluation and repairs. This system was installed from the mid-1960s through the mid-1970s. Deterioration in the wire connections can cause increased resistance to the flow of electric current, resulting in damage that is cumulative in effect. That increased resistance causes overheating, sometimes at hazardous levels, when current is flowing in the circuit. The concerns do not apply to large gauge 240 volt circuits such as SECs, water heaters, dryers, and stoves.

The Consumer Product Safety Commission (CPSC) strongly recommends remediation of single strand aluminum wiring wherever present. They only approve of 3 repair methods, which are outlined next. The CPSC Repair Bulletin can be found at https://www.cpsc.gov/s3fs-public/516.pdf .

Complete removal of all single strand aluminum wiring and replacement with copper wiring is an obvious solution, and is one of the 3 choices approved by the CPSC. However, this is very expensive and disruptive. It is not considered necessary in most cases.

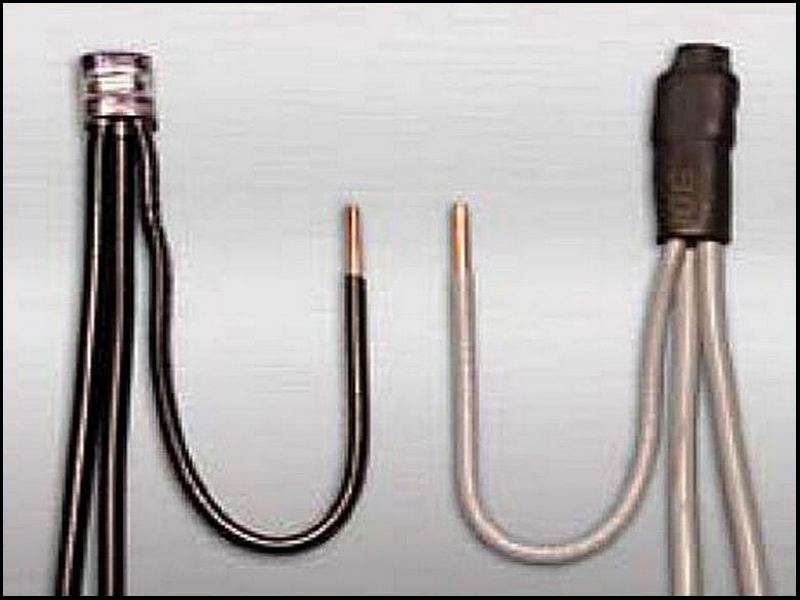

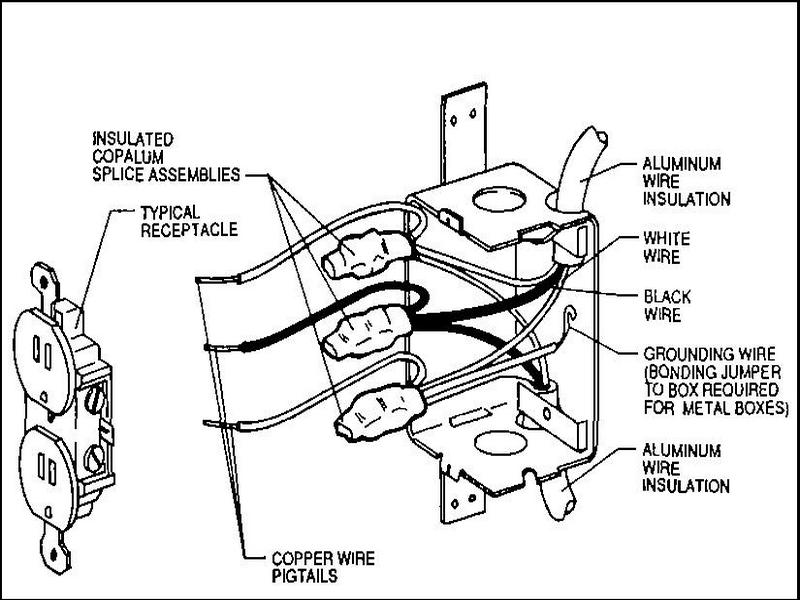

The COPALUM system involves using a special tool and connectors to permanently “cold weld” a short copper pigtail to the aluminum wire termination. The pigtail is then used to make the final connection. This must be done at ALL aluminum wire terminations and connections, including junction boxes, switches, receptacles, and fixtures. Only electricians who are trained by the manufacturer to use the tool properly are authorized to install COPALUM connectors.

The AlumiConnn® connector system is also approved for pigtail remediations. As with the COPALUM system, all connections and terminations must be repaired. However, no certification is required for the AlumiConn® connector. The repair should be conducted by a qualified electrician because careful, professional workmanship and thoroughness are required to make the connector repair safe and permanent.

![]()

![]()

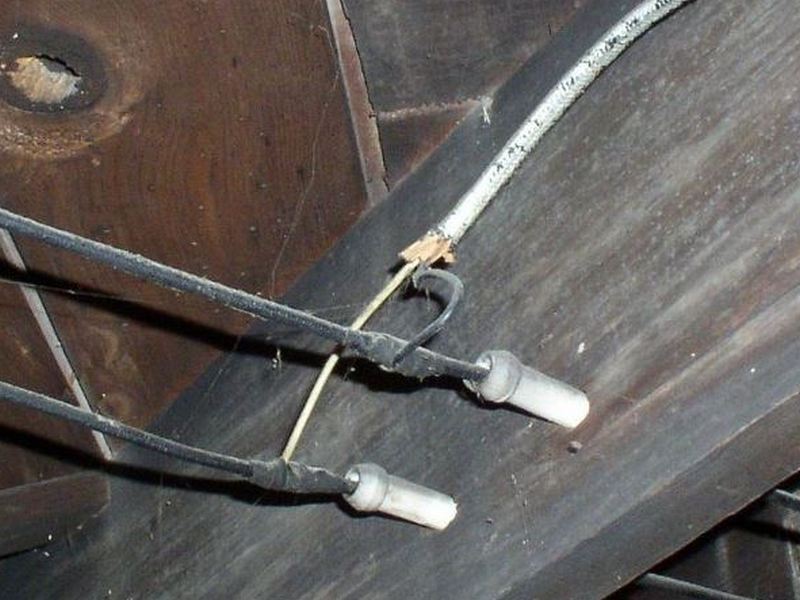

Note that other methods are NOT approved as reliable or permanently safe. This includes CU/AL and CO/ALR devices, e.g. switches and receptacles. Twist-on pigtails, including the Ideal #65 Purple Twister, are not approved.

Failed Ideal #65 Purple Twister

There is single strand aluminum wiring present on 120V circuits. This wiring has an established history of safety problems, including loose connections, arcing, overheating, and fires. Hire an electrician for an evaluation and to make repairs as needed. For further information on aluminum wiring contact the U.S. Consumer Product Safety Commission at: https://www.cpsc.gov/s3fs-public/516.pdf .

Knob and Tube Wiring

Knob and Tube is an early form of standardized wiring, and was installed through to the end of the 1930s. Instead of the single cable with multiple conductors that we use today, it ran separate hot and neutral wires. These copper wires used rubber insulation and a cloth sheathing. They were installed on the framing with stand-off ceramic “knobs”, and passed through the framing inside of ceramic “tubes.” As there are only 2 wires the system cannot be grounded. We always report knob and tube with a recommendation for a further evaluation.

Knob and tube installations are generally grandfathered, and if in good condition it is not, in and of itself, unsafe. The problem is that it’s rarely in really good condition. The rubber insulation can become brittle, and break off when moved by renovations, household activity, or animals. Rodents can damage the wiring. Additionally, new circuits are frequently spliced on in an unsafe manner. In the late 1980s, the NEC banned covering knob and tube with insulation because the wires are supposed to be “air cooled.” While a few western states overrode that prohibition, it still stands everywhere else. Inspect its physical condition carefully, and don’t take a statement about “all old wiring updated” as 100% accurate.

There is knob and tube wiring present. This older system cannot be grounded, and often has brittle or damaged insulation. The wiring should be evaluated for condition and safety concerns. Hire an electrician for an evaluation and to make repairs as needed.

There is knob and tube wiring present which is covered with insulation. This is not permitted due to the potential for heat buildup. The wiring should be evaluated for condition and safety concerns. Hire an electrician for an evaluation and to make repairs as needed.

Cloth Sheathed Wiring

Cloth sheathed cable is an early form of “NM” or non-metallic cable. Unlike modern, so-called “Romex” NM wiring, the outer casing is a cloth braid. It was installed primarily from the 1930s through the 1960s. It is almost always a 2-wire system and cannot be grounded. It is rubber insulated and shares some of the same vulnerability to physical damage as knob and tube.

While cloth sheathed wiring does not warrant the same level of concern as knob and tube, it should always be inspected carefully where visible. Damage or signs of overheating must be reported, and when in doubt recommend a further evaluation.

There is cloth sheathed wiring present. Cloth wrapped wiring is one of the early forms of branch circuit wiring methods. This is a potential safety hazard if the insulation degrades or breaks, leaving areas of the wiring exposed. Hire an electrician for an evaluation and to make repairs as needed.

There are loose or damaged cover plates. This is a safety concern that defeats the enclosure’s fire rating and permits contact with energized components. Secure or replace the cover plates.

There are missing cover plates. This is a safety concern that defeats the enclosure’s fire rating and permits contact with energized components. Secure or replace the cover plates.

There are missing junction box knockout covers. This is a safety concern that defeats the box’s fire rating and permits contact with energized components. Hire an electrician to make required repairs.

There are improperly secured junction boxes. This is a safety concern that can damage wire connections. Hire an electrician to make required repairs.

There are damaged or missing weather-rated covers. This is a shock hazard in wet areas. Install or replace the weather-rated cover.

Some sections of the wiring conduit are loose. This is a potential shock hazard. Hire an electrician to make required repairs.

The conduit is damaged, exposing the wires inside. This is a shock and a safety hazard. Hire an electrician to make required repairs.

There is exposed and unprotected wiring. This is a safety hazard. Hire an electrician to make required repairs.

There are loose or hanging wires. This is a safety hazard. Hire an electrician to make required repairs.

There are improperly secured wires at an appliance or electrical junction box. Safety standards require a retainer where wires enter a box or device. Hire an electrician to make required repairs.

The wire sheathing is damaged. This is a shock and fire hazard. Hire an electrician to make required repairs.

There are exposed branch circuit ends. All wire terminations must be in a permanently-accessible approved junction box, with a cover, for safety. This is a safety hazard. Hire an electrician to make required repairs.

There are exposed wire splices. This is a safety hazard. All wiring splices must be in an approved junction box with a proper cover and permanently accessible. Hire an electrician to make required repairs.

There is wiring installed outside that is not rated for the exterior. This is a safety hazard as the wire is vulnerable to deterioration. Hire an electrician to make required repairs.

There is wiring installed directly in the ground that is not rated for burial. This is a safety hazard as the wire is vulnerable to deterioration. Hire an electrician to make required repairs.

There is an extension cord being used as permanent wiring. This is a safety hazard. Hire an electrician to make required repairs.

There is wiring installed in direct contact with metal HVAC ductwork. This is a safety hazard that could electrify the ducts. Hire an electrician to make required repairs.

There is wiring which is routed through the floor, a wall, or under a carpet. This is unsafe and is a fire and shock hazard. Hire an electrician to make required repairs.

There is wiring located too close to a heat source. Wires should have adequate clearance from any hot pipes, ducts, or flues. Hire an electrician to make required repairs.