It’s vital to be clear about electrical terms. Our component “Electrical – Panel” refers to the first Overcurrent Protection Device (OCPD/breaker/fuse) after the service entry. This equipment disconnects the utility’s power from the building at the customer’s end of the service entrance conductor (SEC). In most cases, this will also be the “service panel”, or “main breaker panel.” However, if the service entry is a distance from the service panel, a single OCPD disconnect will be installed close to the entry. This main disconnect then becomes the component that we refer to as the “main” panel. What the homeowner will view as the “breaker box” is now actually a “sub panel”. This is a critical point to understand, as sub-panels must be wired differently than service panels.

Confirm a securely mounted, well-labeled service panel, free of openings, damage, or deterioration. The interior “dead front” cover must be removed, or reported that it could not. Look for overheated wires, oversized, loose, or damaged breakers/fuses, double taps, and mismatched components. Be alert to “problem” panels that are unsafe. All circuits in a service panel must be able to be de-energized with no more than 6 breakers.

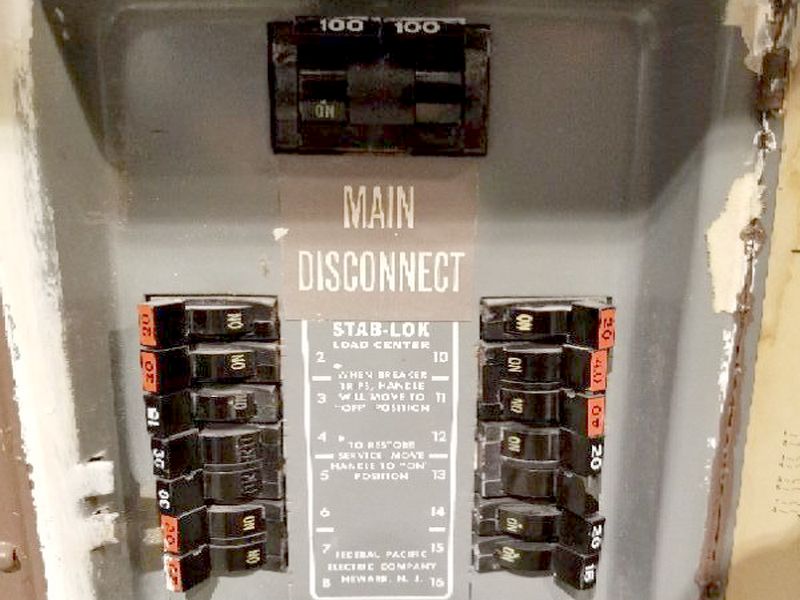

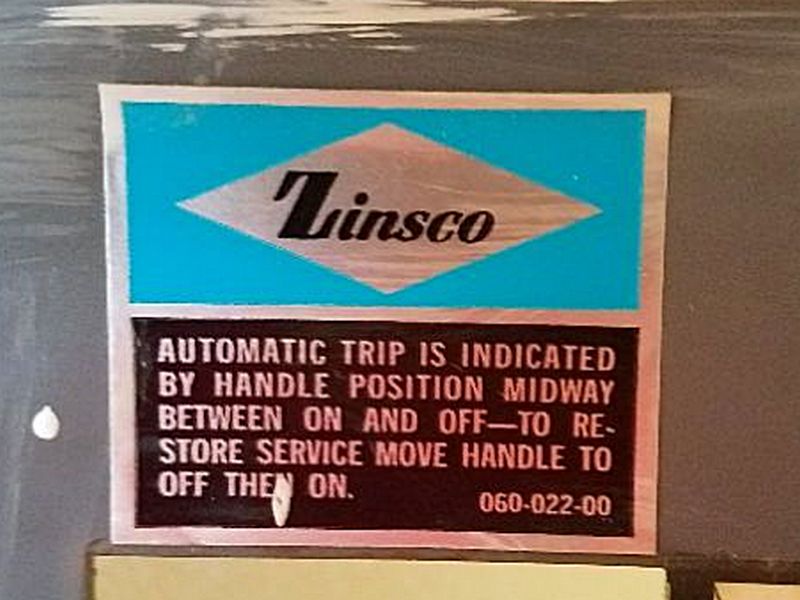

The following panels and breakers should always be reported as a defect regardless if there are issues visible or not. They have a documented history of safety concerns. Use the provided language to recommend a panel replacement or breaker evaluation.

There is a Federal Pacific Electric breaker panel present. These panels have an established history of safety issues, including overheating and arcing. Hire an electrician to replace the panel.

There is a Zinsco/Kearney breaker panel present. These panels have an established history of safety issues, including overheating and failing to trip. Hire an electrician to replace the panel.

There is a Pushmatic breaker panel present. There have been reports of safety issues involving failures to trip due to a less reliable mechanism. Additionally, the breakers can become difficult to operate and not show a tripped status. Hire an electrician for an evaluation and to make repairs as needed.

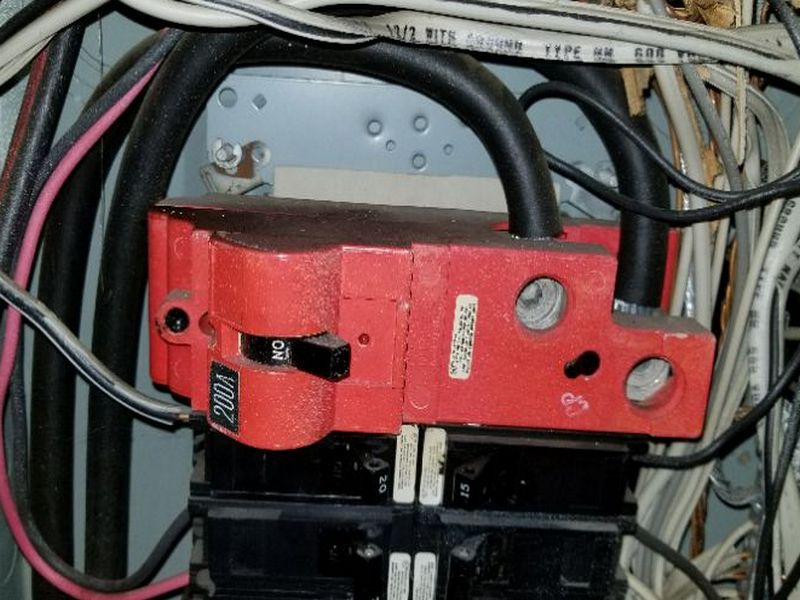

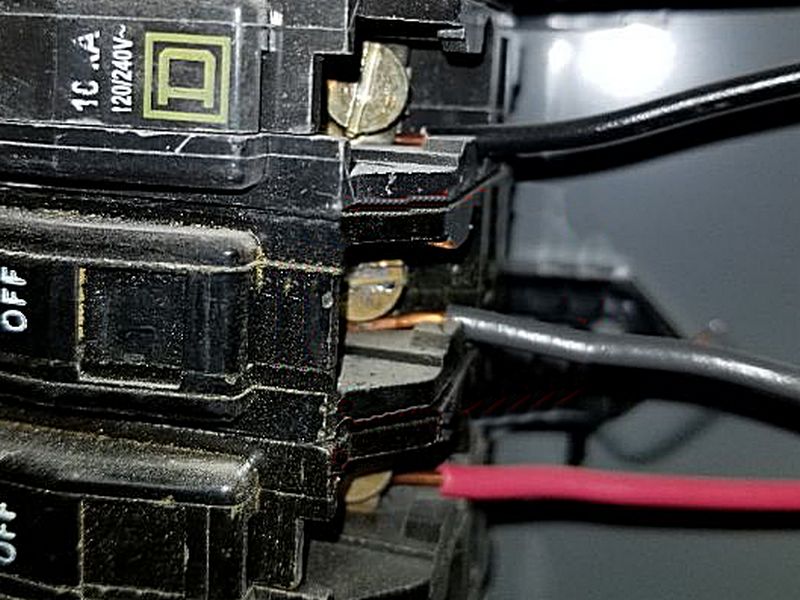

There is a Murray brand breaker panel with a “red” main breaker installed. There have been reports of problems with these breakers, including overheating and arcing at the breaker connections. Hire an electrician for an evaluation and to make repairs as needed.

There are missing blunt-tipped screws at the electrical panel’s cover. This is a safety requirement to ensure an adequate seal around the panel box. Hire an electrician to install blunt-tip screws.

There are pointed screws securing the electrical panel’s cover. These can penetrate a conductor and cause a shock hazard. Hire an electrician to replace the screws.

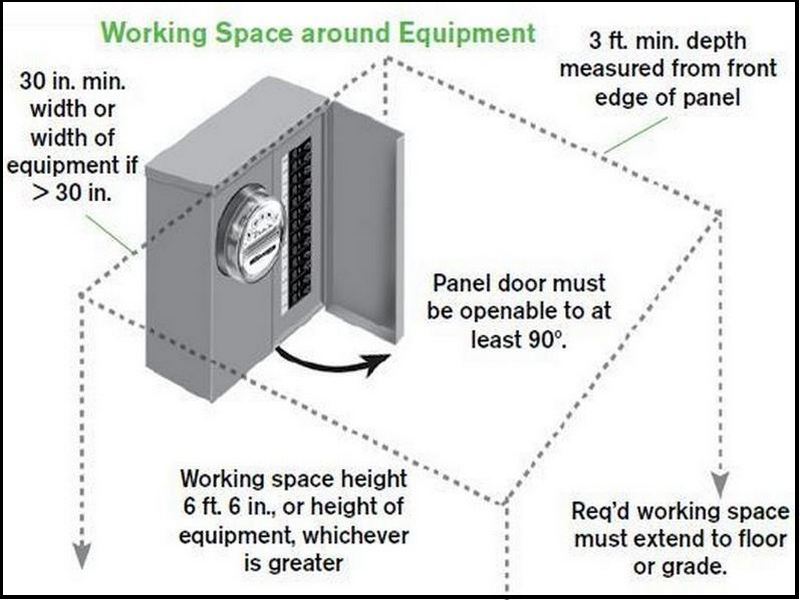

There is inadequate clearance at the electrical panel. A minimum of 36″ is required in front of the panel, and the door must open to 90. Remove the obstructions.

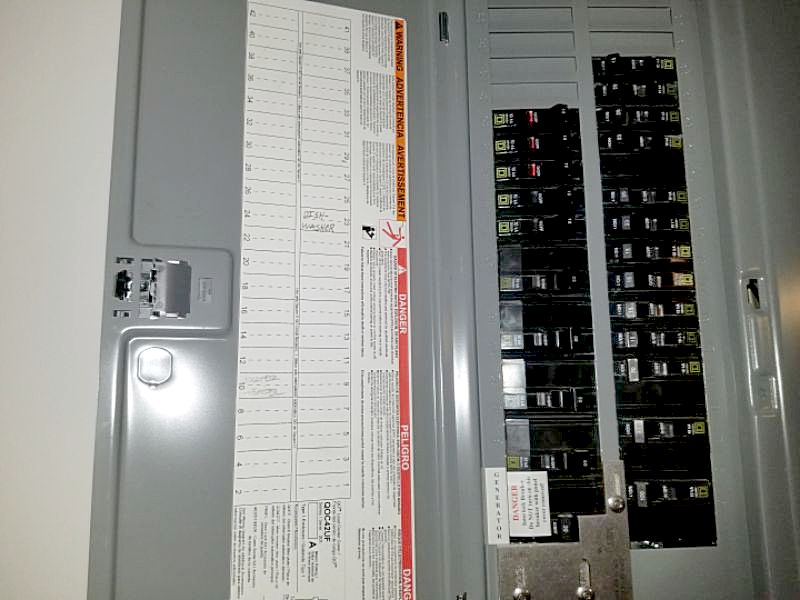

The electrical panel is partially labeled. All panels should be labeled correctly to indicate which circuits the breakers or fuses serve. Relabel the panel.

The electrical panel is improperly secured to the wall. This is a safety hazard. Hire an electrician to make the required repairs.

There are missing knockout covers at the electrical panel. This defeats the panel’s fire rating, and permits accidental contact with energized components. Hire an electrician to make the required repairs.

The electrical panel is missing a “dead front” cover. This is a safety hazard as the energized interior components are exposed. Hire an electrician to install a cover.

The electrical panel is in an improper location. Safety requirements prohibit panels in bathrooms, clothes closets, or over stairways. Hire an electrician for an evaluation and to make repairs as needed.

The electrical panel is recessed into a finished wall, creating a gap between the panel cover and its enclosure. This is a shock hazard and defeats the panel’s safety rating. Hire an electrician to make the required repairs.

There is moisture in the electrical panel. Rust and corrosion affect a panel’s safe operation. The cause of the moisture must be identified. Hire an electrician for an evaluation and to make repairs as needed.

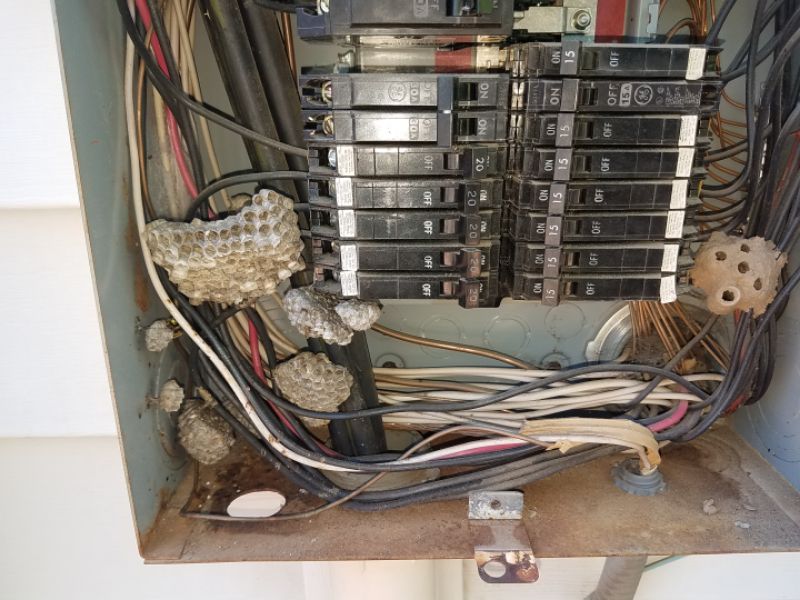

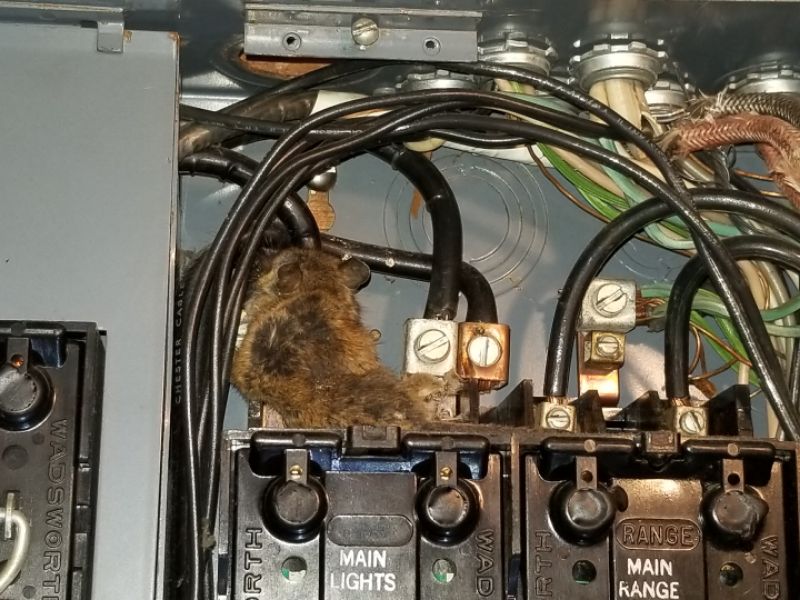

There are animals nesting in the electrical panel. This is a safety hazard. The entry point should be identified and sealed. Hire an electrician for an evaluation and to make repairs as needed.

A breaker or fuse is an Overcurrent Protection Device, or OCPD. Its job is to clear ground faults to prevent shock hazards, and to protect the circuit wiring. Excess electrical current can cause a conductor to overheat and fail, creating a fire hazard. This is why the wiring’s current rating is the determining factor in a circuit’s capacity, and hence what the OCPD should be.

In copper household wiring, a 12 AWG NM or “Romex” conductor is rated for 20 amps, while a comparable 14 AWG is only allowed 15 amps. Note that the example says copper. Aluminum is not as good an electrical conductor as copper. In a 120 volt circuit using single-strand aluminum wiring, the conductors must be one size larger. Hence, a 15 amp OCPD on a circuit must feed 12 AWG single-strand aluminum wire, not 14 AWG. You should become familiar with common wire gauges so you can visually identify them. Many inspectors carry small, labeled samples of the most common wires sizes. Modern NM cable is color-coded.

There are oversized breakers at the electrical panel. This is a safety hazard. When a breaker has a higher rating than the wire it serves, the wire will overheat before the breaker trips. Hire an electrician to replace the breakers.

There are oversized fuses at the electrical panel . This is a safety hazard. When a fuse has a higher rating than the wire it serves, the wire will overheat before the fuse blows. Replace the fuse with a correct-size one.

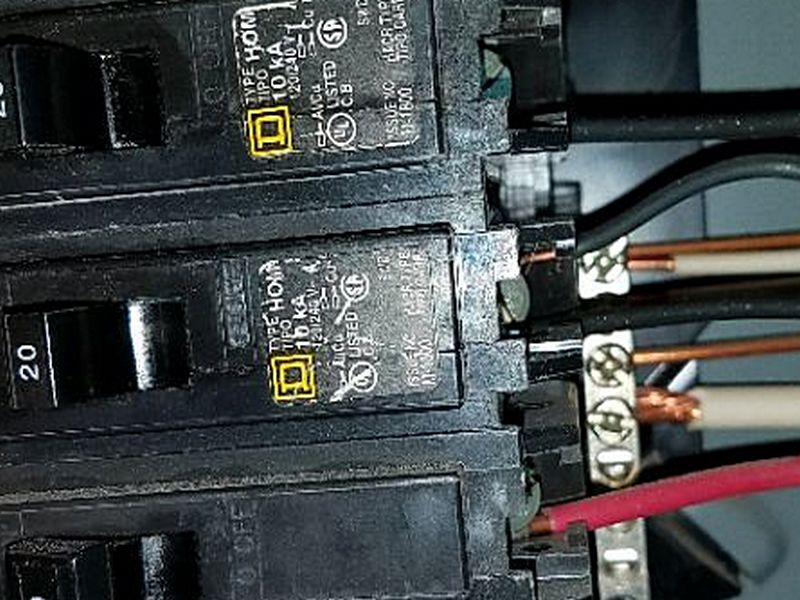

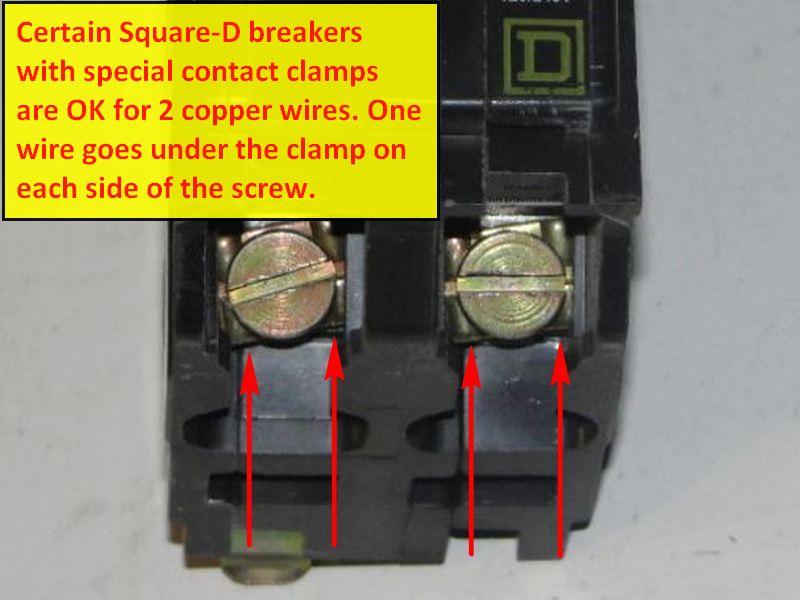

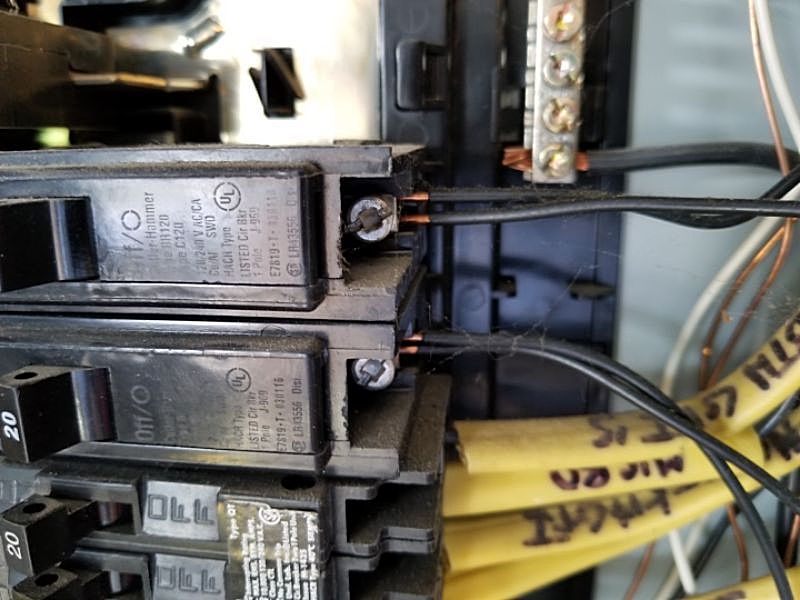

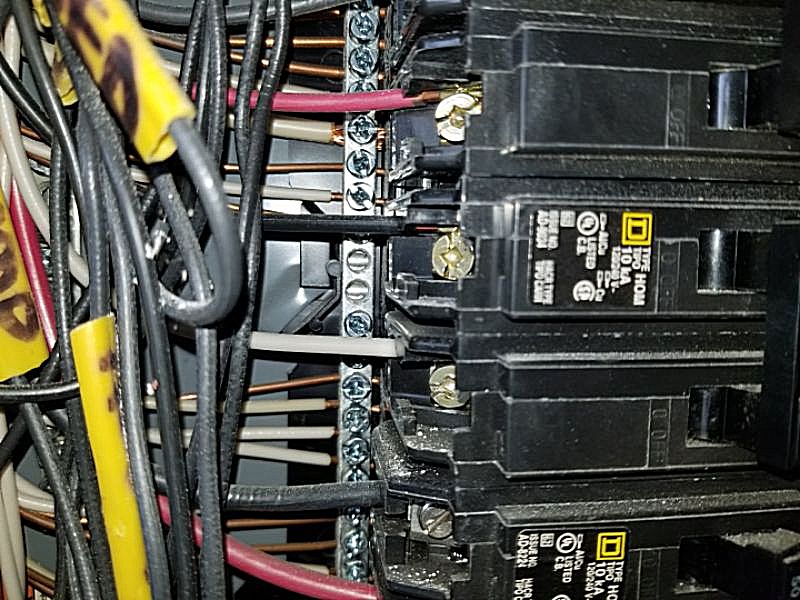

There are double-tapped breakers or fuses at the electrical panel. Most contacts are not designed to safely secure more than one wire. Hire an electrician to make the required repairs.

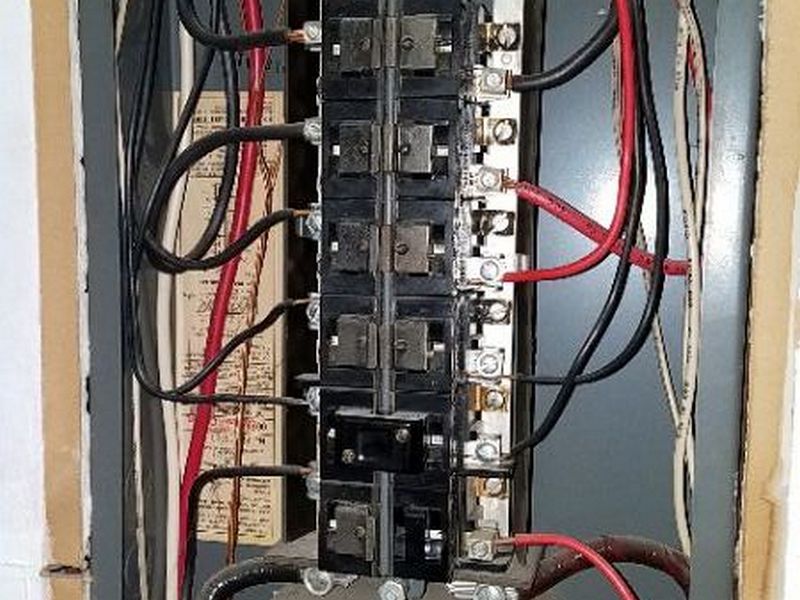

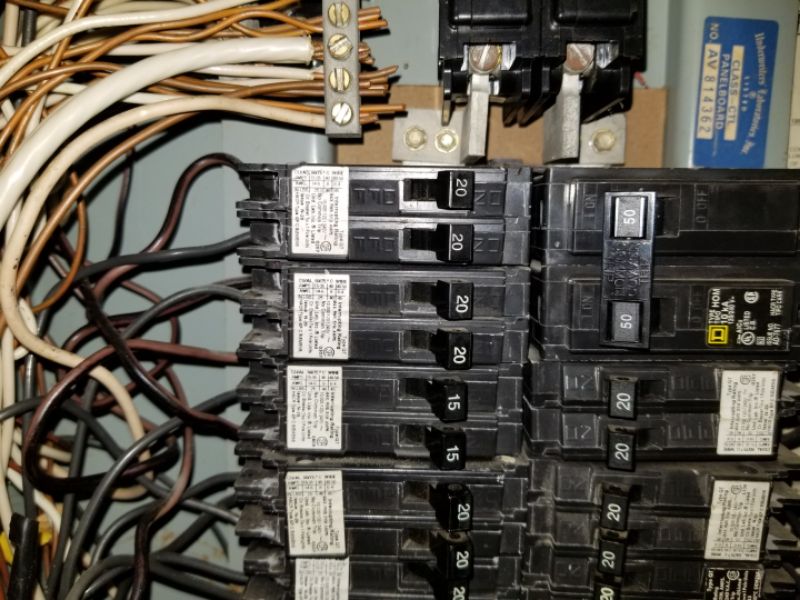

There are incompatible breakers installed at the electrical panel. Breakers not approved by the panel’s manufacturer can affect safe operation. Hire an electrician to make the required repairs.

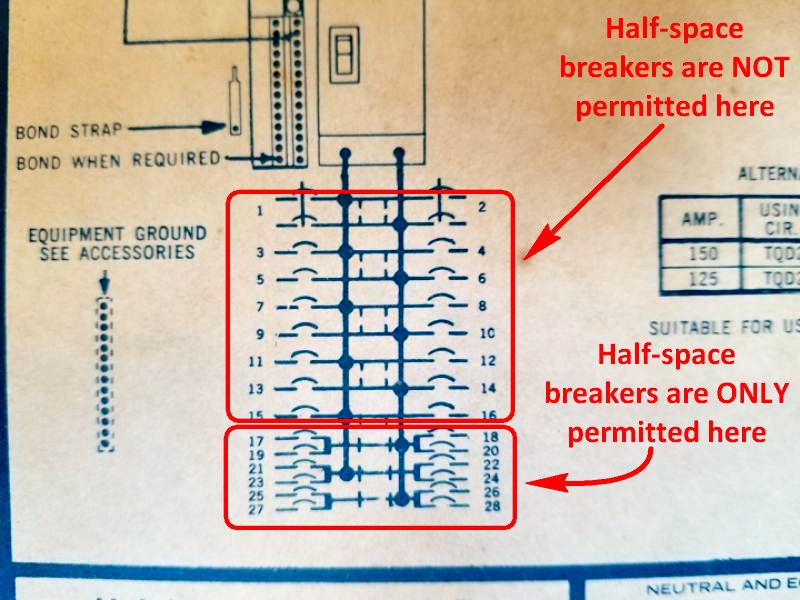

There are improperly-installed half-space breakers at the electrical panel. The manufacturer provides a chart indicating what type of devices can be used and where they can be placed. Hire an electrician to make the required repairs.

There are loose breakers at the electrical panel. This is a safety hazard due to the potential for arcing and overheating. Hire an electrician to repair or replace the breakers.

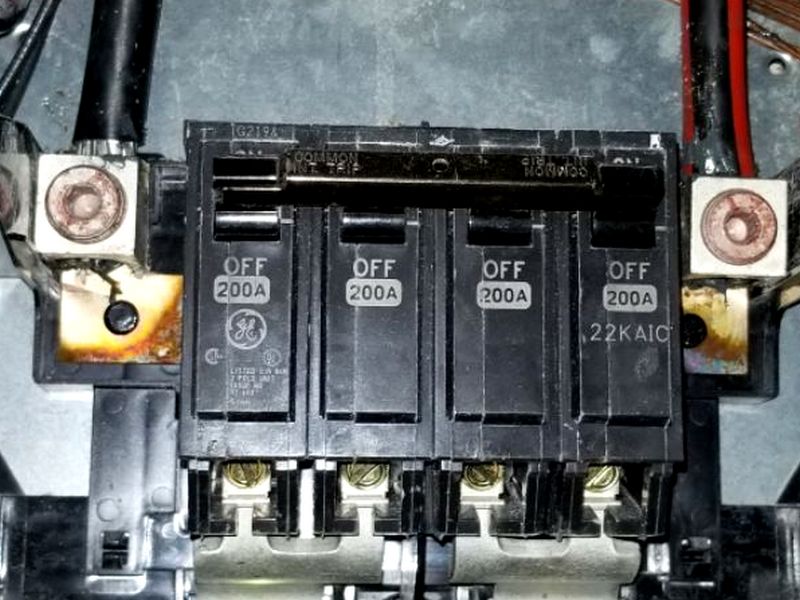

There are breakers in the electrical panel that are in the off position. The reason for this is not known. We do not turn on breakers. Hire an electrician for an evaluation and to make repairs as needed.

There are missing tie bars for two-pole breakers at the electrical panel. These are required to ensure that both legs of the breakers trip together. Hire an electrician to install tie bars.

The electrical panel requires more than 6 breakers to turn off all the power to the home. This is contrary to accepted practice and is a safety concern. Hire an electrician to evaluate the panel and to make required repairs.

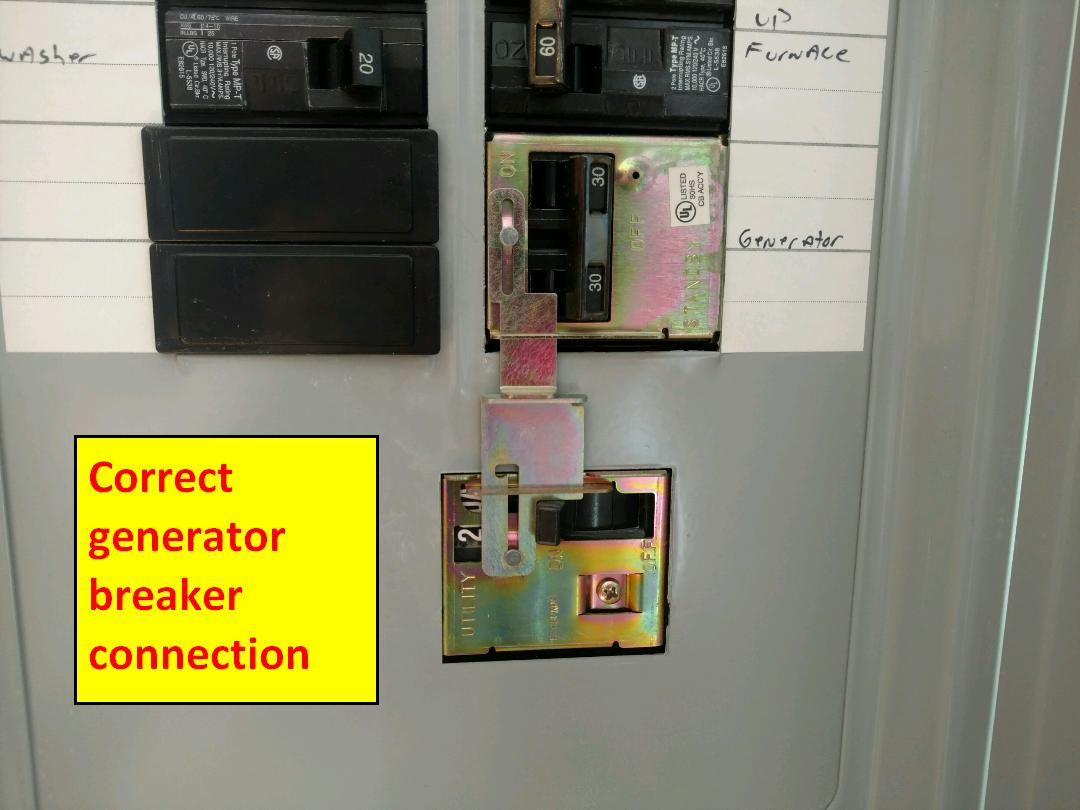

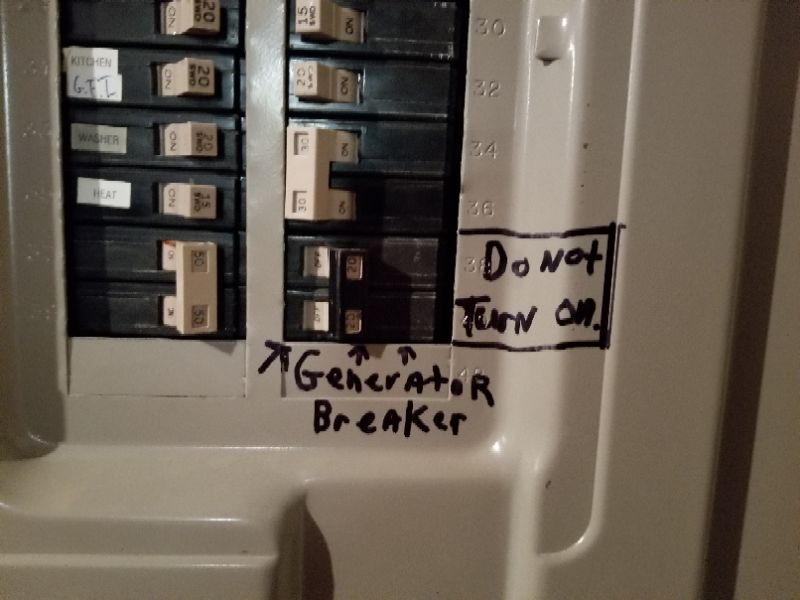

There is an improper generator connection at the electrical panel. The installation must ensure that the utility’s main breaker and the generator’s input breaker cannot be “on” at the same time. Hire an electrician to make the required repairs.

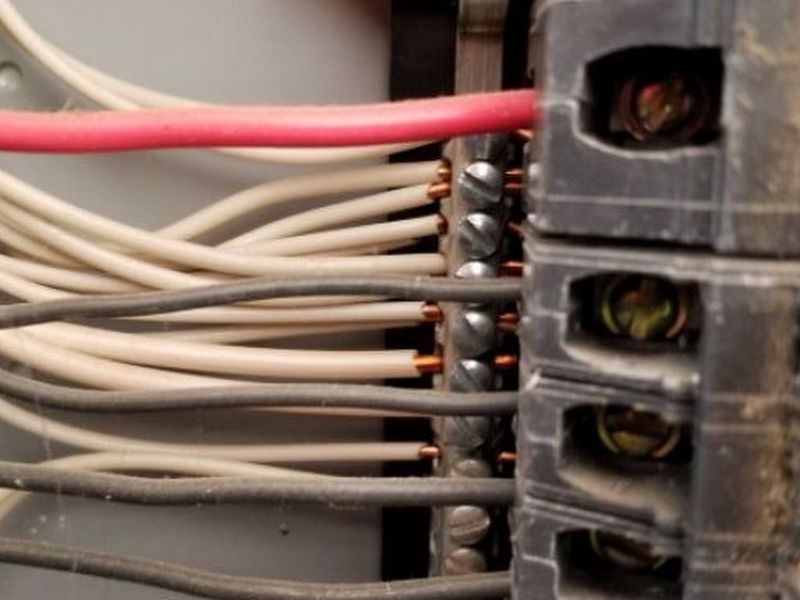

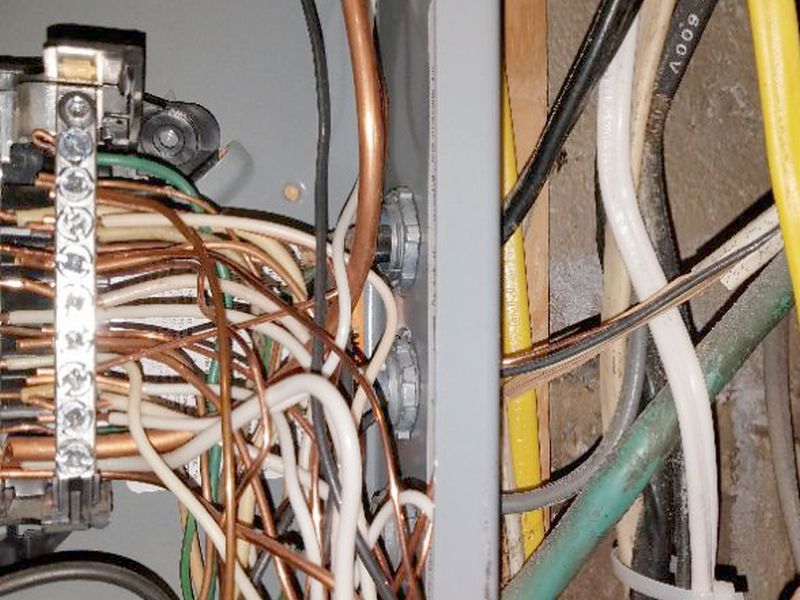

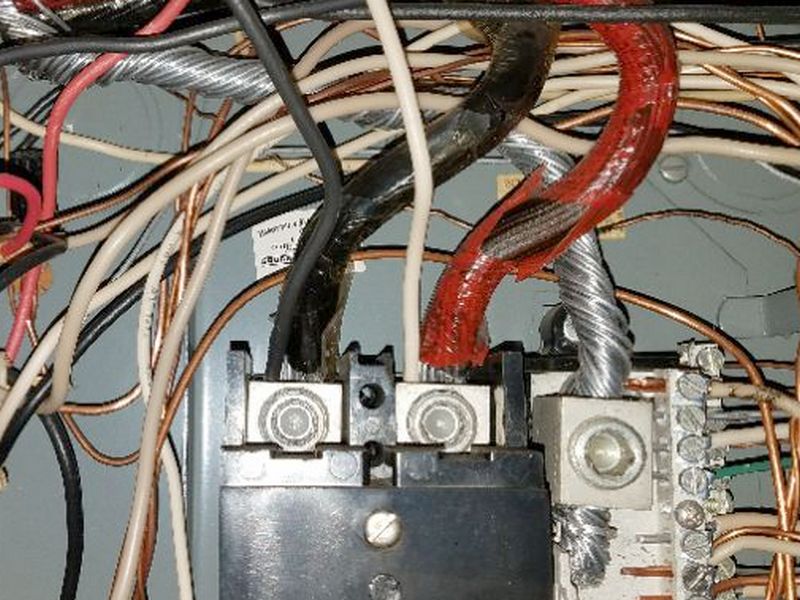

There are improperly secured wires at the electrical panel. Safety standards require a retainer where wires enter the panel. Hire an electrician to make the required repairs.

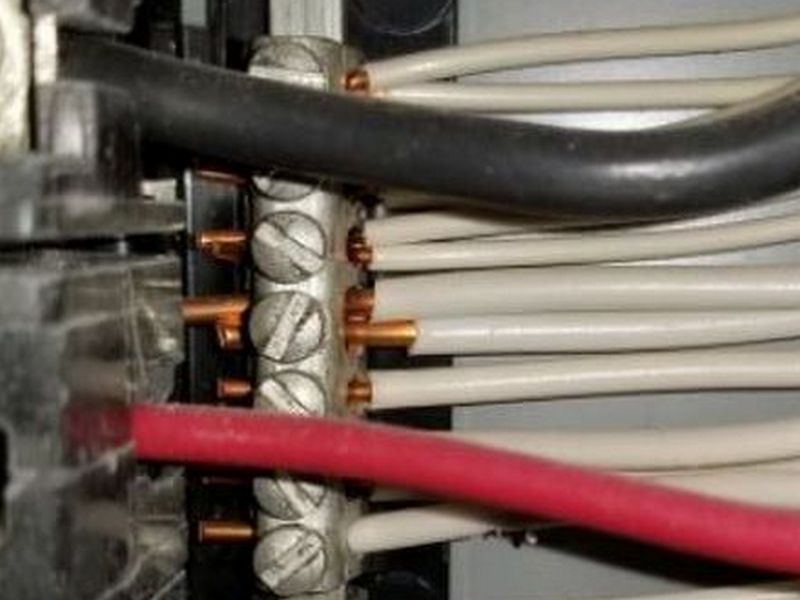

There is more than one neutral wire connected to a single contact on the neutral bar. This is no longer permitted as most contacts are not designed to safely secure multiple wires. Hire an electrician to make the required repairs.

There are unmarked neutral wires connected to double-pole breakers or fuses. This is a safety hazard. Neutral wires must be marked to indicate that they are current-carrying conductors. Hire an electrician to make the required repairs.

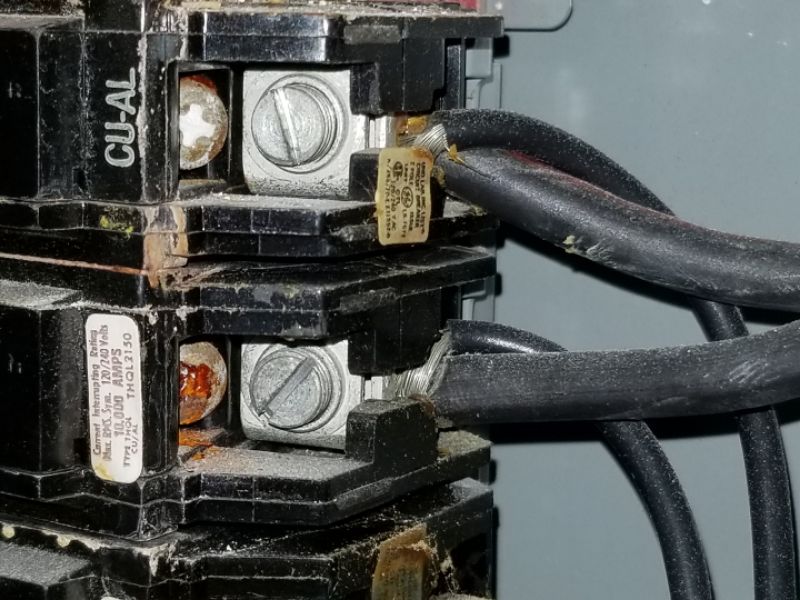

The electrical panel’s aluminum connections are missing antioxidant paste. This is a safety requirement. Hire an electrician to apply antioxidant paste.

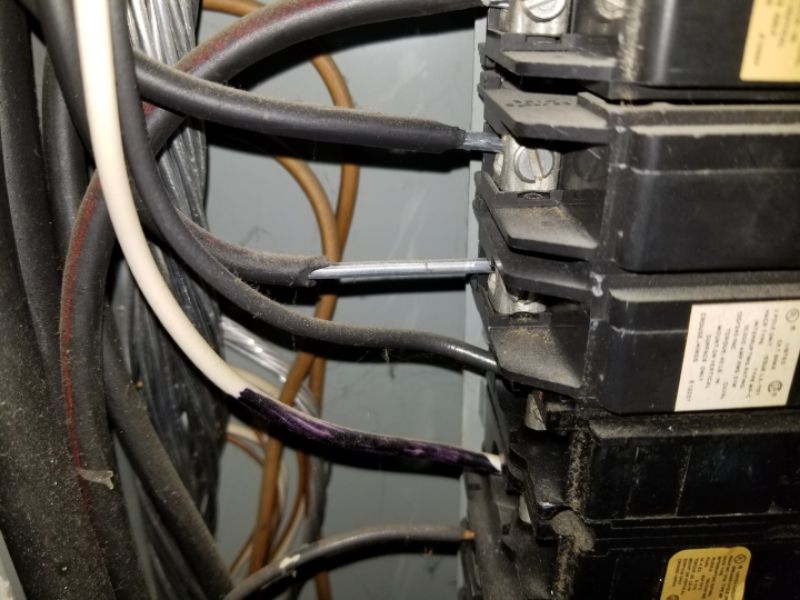

There is excessive sheathing missing from the wiring where it connects to the breakers at the electrical panel. This is a safety hazard. Hire an electrician to make the required repairs.

There are loose wire connections at the electrical panel. This is a safety hazard due to the potential for arcing and overheating. Hire an electrician to make the required repairs.

There are improperly terminated wires inside the electrical panel. This is a safety hazard. Hire an electrician to make the required repairs.

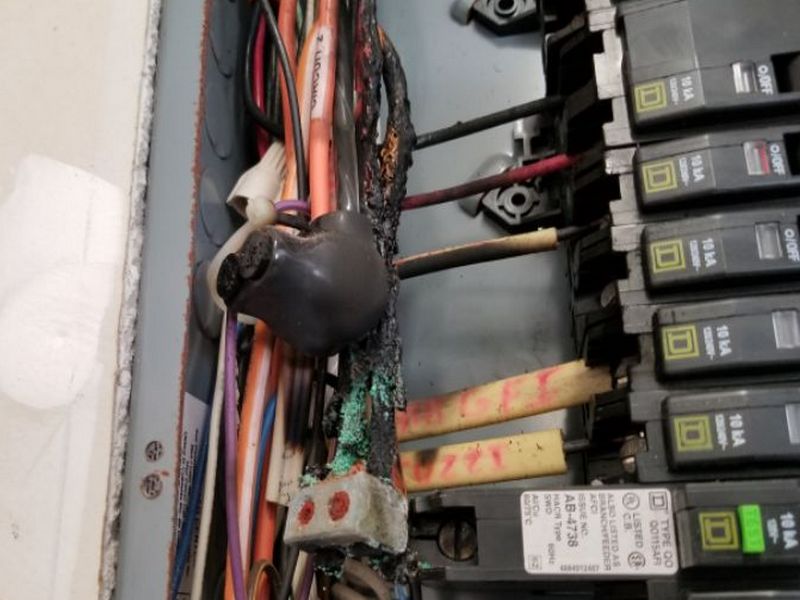

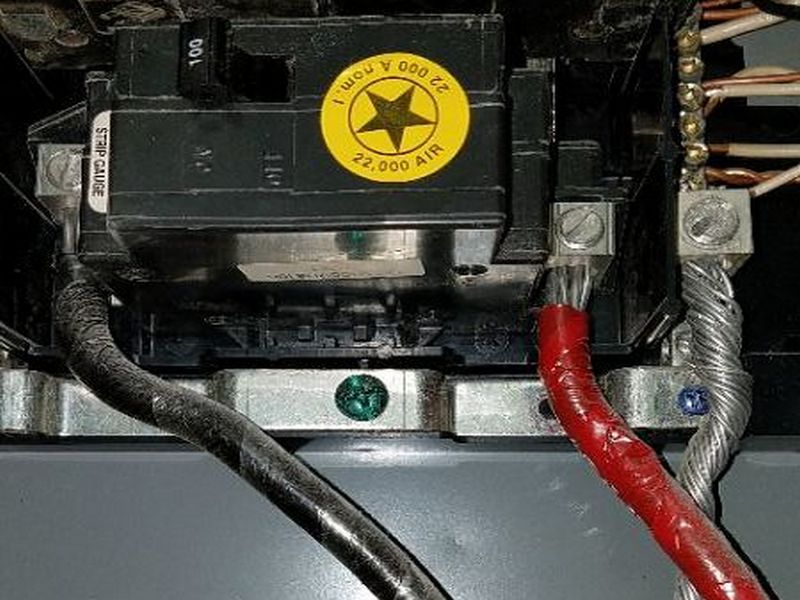

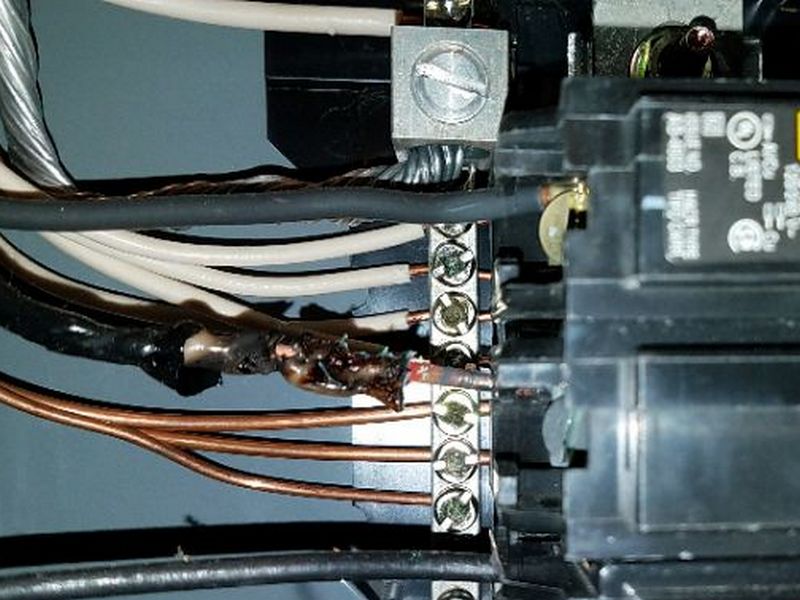

There are overheated wires at the electrical panel. This is a safety hazard. The reason for this must be identified. Hire an electrician for an evaluation and to make repairs as needed.

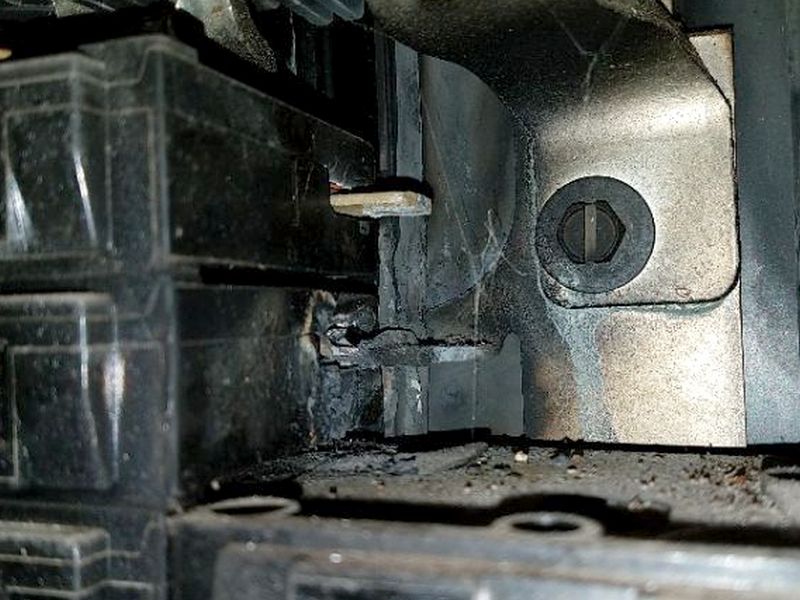

There are scorch marks inside the electrical panel. This indicates arcing and/or overheating. The cause of the problem must be identified. Hire an electrician for an evaluation and to make repairs as needed.

There are improper taps on the main lugs at the electrical panel. This is a safety issue. Hire an electrician to make the required repairs.

There is a doorbell transformer installed inside the electrical panel. This is not permitted for safety reasons. Hire an electrician to make the required repairs.