“Fuel Burning Appliances” have all of the concerns of fireplaces and then some. Free-standing stoves bring the fire out into the room, along with its flue pipe. With an insert, we are marrying a combustion appliance with an existing fireplace. We must be concerned with how they are connected even though we often cannot see that part of the installation. Additionally, wood stoves and inserts can load considerably more combustion byproducts into the system than a simple fireplace.

As with fireplaces, safety comes first. But you must make the effort as needed to inspect inside a stove or insert. If possible, look behind the insert’s front to view the flue connections. Inspect any exposed flue pipes for correct connections. Evaluate the clearances around the appliances and their vents. Assess the doors, dampers, and the combustion chamber. If it’s a gas device, make sure that all appropriate valves and pipes are workmanlike.

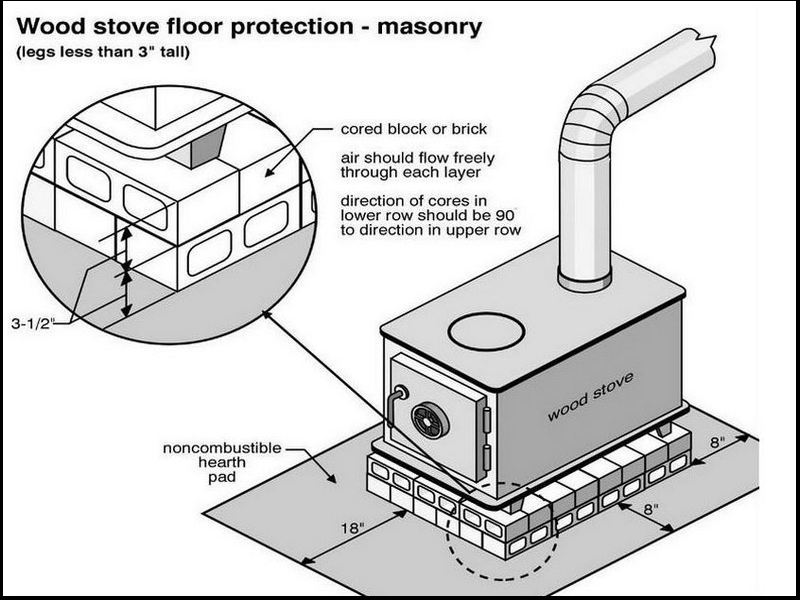

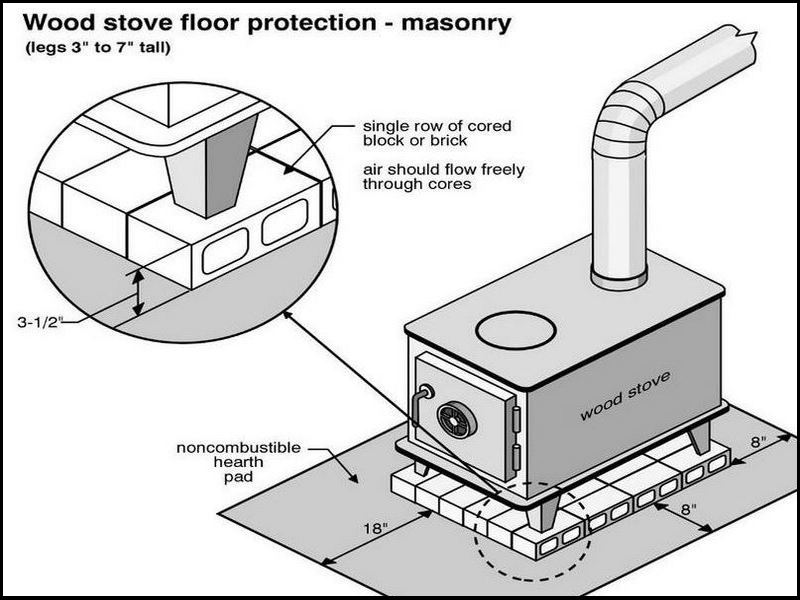

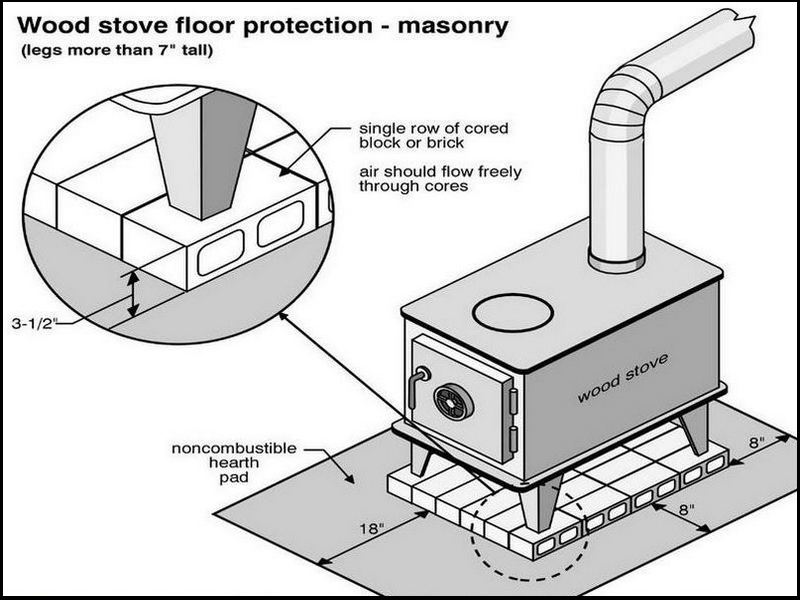

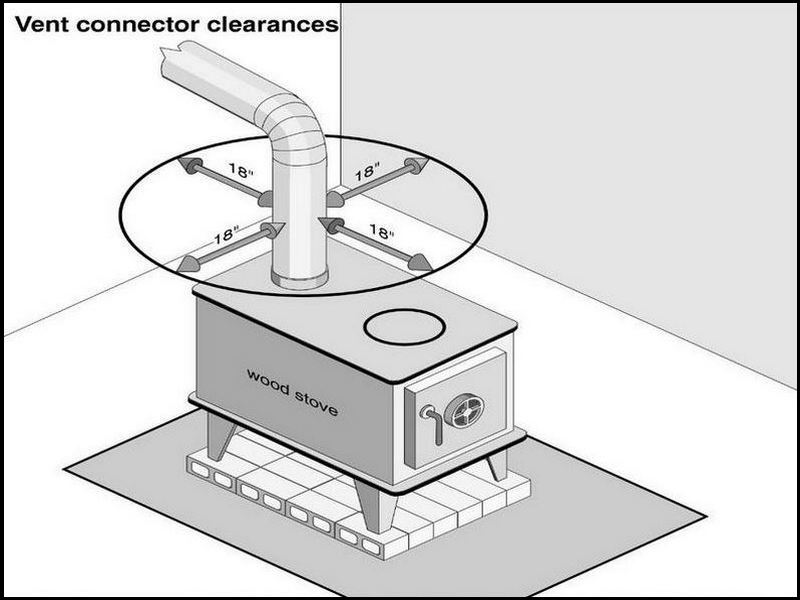

What follows in this section are general guidelines on the clearances required around a wood stove installation. It is important to understand that there are not hard and fast rules that can be applied in any case. What always take precedence is “AMI”, or “in accordance with manufacturer’s instructions.” In short, if the maker says their stove can be installed this way, it almost always overrules “code.”

Additionally, in the absence of AMI, or an “unlisted” device, the rules vary depending on many details. These include the actual appliance, the surrounding installation, and what specific code applied at the time. Use common sense, and when in doubt call for a specialist’s opinion.

The appliance is too close to combustible material. This is a safety issue. Remove the combustible materials or relocate the appliance.

There are cracks in the firebox. This is a fire hazard. Repair and seal the cracks.

The firebox is deteriorated. This is a fire hazard. Replace the firebox or the liner.

The vent pipe is too close to combustible material. This is a safety issue. Remove the combustible materials or relocate the vent pipe.

There are gaps in the vent pipe. This is a fire hazard. Repair and seal the gaps.

The vent pipe is improperly sloped. This is a safety hazard. Reinstall the vent pipe with a proper slope.

The vent pipe is damaged or deteriorated. This is a safety hazard. Replace the vent pipe.

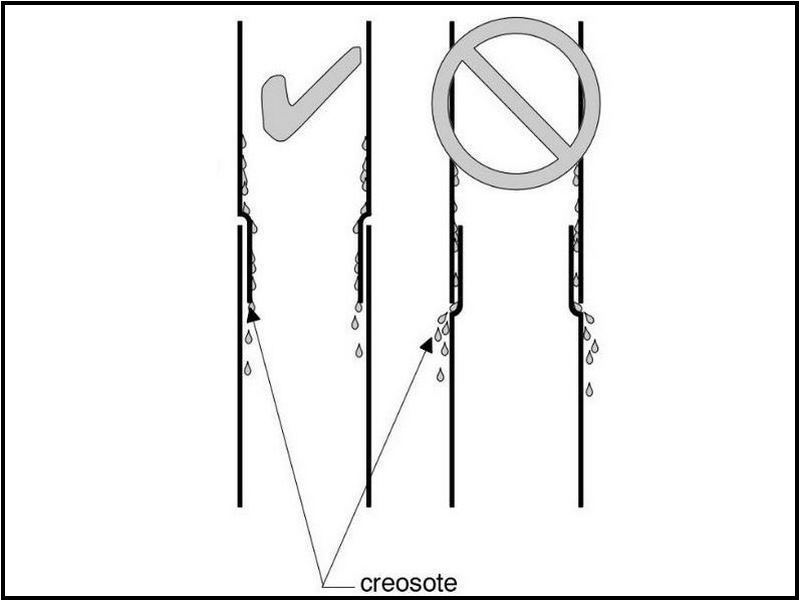

The wood stove’s vent sections are improperly connected. The crimped, male connection should be at the top and inserted downward into the female connection. Otherwise, the solid fuel resins and condensation can leak through the joints. This is a safety concern. Hire a contractor to reinstall the vent with reversed connections.

There is creosote accumulation in the firebox and vent pipe. This is a fire hazard. Hire a contractor to clean the chimney and conduct a detailed inspection.

Wood stove inserts are inspected for many of the same concerns as a free-standing stoves. The main difference, and the primary limitation, is that the entire back half is “inserted” into the existing fireplace. It is not visible. We do not slide inserts out of the fireplace. As such, any problems with the flue connections are hard to see, although you can sometimes look behind the surround cover plate.

Wood stove installations must have a continuous flue connection from the stove to the existing chimney flue. An ideal method is to use an approved metal flue pipe that extends all the way to the exterior. Exhausting the stove directly into the fireplace’s firebox or smoke shelf instead of sealing the pipe to the chimney flue is unsafe.

The wood stove insert lacks a direct and sealed connection to the chimney flue. This is sometimes referred to as a “slammer.” This is contrary to accepted practice and is unsafe. Hire a contractor to install a connection to the chimney flue.

The wood stove insert is installed in a system designed for a pre-fabricated fireplace. This is contrary to accepted practice and is unsafe. Hire a contractor for an evaluation and repairs or replacements as needed.

The gas fireplace insert has an operable damper without a clamp that prevents the damper from closing completely. This is a safety hazard. Install a damper clamp.

The valve is installed inside the fireplace. This is a safety hazard. The appliance should have master shut-off valve that is outside of the firebox and readily accessible (i.e., in the same room). Hire a contractor to relocate the valve to outside of the fireplace.

The opening is not sealed in the firebox where the gas appliance’s fuel line enters. This is a fire hazard. Seal the opening.

The fireplace’s direct vent terminates in a readily-accessible location. This is a safety hazard, especially for small children. Install an after-market protective vent cover.

The fireplace’s direct vent terminates in a readily-accessible location. This is a safety hazard, especially for small children. Install an after-market protective vent cover.

The gas flame is yellow, too high, and is burning on the gas logs. This is a safety hazard that indicates improper adjustment and operation. Hire a contractor for an evaluation and repairs as needed.

NFPA 211 is the basis of applicable chimney and fireplace safety codes. The actual adoption of a given code varies by state and locality. However, the Chimney Safety Institute of America (www.CSIA.org), the leading educational and certification organization for chimney professionals, fully recognizes NFPA 211. This includes its standards for chimney and fireplace inspections. These protocols are designated Level I, II, and III Inspections.

DEFINITIONS:

Readily Accessible:

Exposed, or capable of being exposed, for operation, inspection, maintenance, or repair without the use of tools to open or remove doors, panels, or coverings.

Accessible:

Capable of being exposed for inspection, maintenance, or repair, without damage to the chimney or building structure or finish, but which may require the removal of doors, panels, or coverings using commonly available tools.

LEVEL I INSPECTION

Scope: Readily accessible areas of chimney, structure, and flue; lack of flue obstructions or combustible deposits; basic appliance installation and connections.

Access required: Readily accessible portions of chimney exterior and interior; accessible portions of appliance and chimney connection.

Circumstances: Annual inspection during routine flue cleaning; upon direct replacement of connected appliance with one of similar type, input rating, and efficiency.

LEVEL II INSPECTION

Scope: All subjects of a Level I inspection; proper construction and condition of accessible chimney structure and flue; proper clearances from combustibles in accessible locations; size and suitability of flues for connected appliances.

Access required: All accessible portions of chimney exterior and interior, including accessible areas of attics, crawl spaces and basements; accessible portions of appliances and chimney connections; includes flue inspection by video scanning or other means.

Circumstances: Upon removal of one or more connected appliances and replacement with one of dissimilar type, input rating, or efficiency; prior to relining or replacement of flue lining; upon sale or transfer of the property; after operating appliance malfunction or external event, e.g. earthquake, severe weather event, likely to have caused chimney damage.

LEVEL III INSPECTION

Scope: All subjects of Level I and Level II inspections; proper construction and condition of concealed portions of chimney structure and enclosed flues; proper clearances from combustibles.

Access required: Internal and external portion of chimney structure including concealed areas of the building or chimney; includes removal of components of the building or chimney where necessary, but only as necessary to gain access to areas that are the subject of the inspection.

Circumstances: When necessary for the investigation of an incident that has caused damage to the chimney or building; where a hazard detected or suspected as the result of a Level I or II inspection cannot be fully evaluated without access to concealed areas.